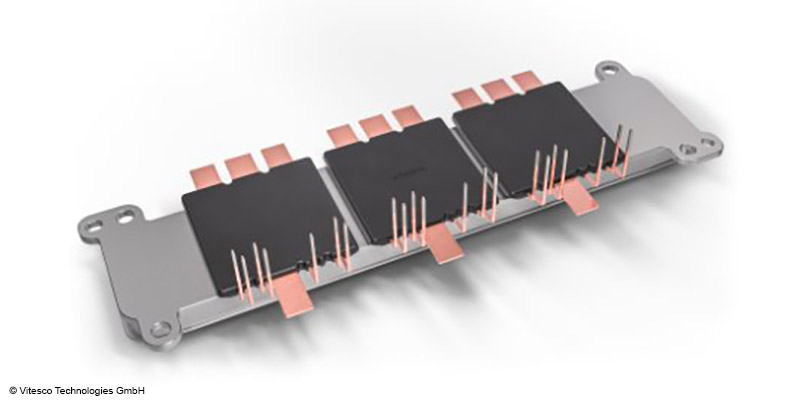

Vitesco Technologies, a German powertrain supplier, has introduced a cutting-edge power module produced through the transfer molding process. This innovative power module is slated for delivery to a major global car manufacturer by mid-2025.

Comprising three overmold half-bridges, the new power module is set to become the cornerstone of power electronics systems designed to control drive energy and recuperation in electric vehicles. Vitesco Technologies emphasizes that these overmold power modules leverage state-of-the-art silicon carbide (SiC) chip technology combined with overmolding, resulting in a remarkably robust product characterized by increased power density, cost-efficiency, and reduced weight.

Thomas Stierle, a board member and the head of the Electrification Solutions Division at Vitesco Technologies, highlights the company’s strategic approach of utilizing scalability and modularity in power electronics development. Stierle states, “Combined with our extensive overmolding expertise, we can deliver an extremely robust product to our customers. This is yet another example of how we successfully transfer proven technology to an electrification product.”

The transfer molding process involves sealing the power electronics beneath a dielectric material, providing exceptional protection to the components. Vitesco Technologies has been employing this process since 2020, initially for compact transmission control units.

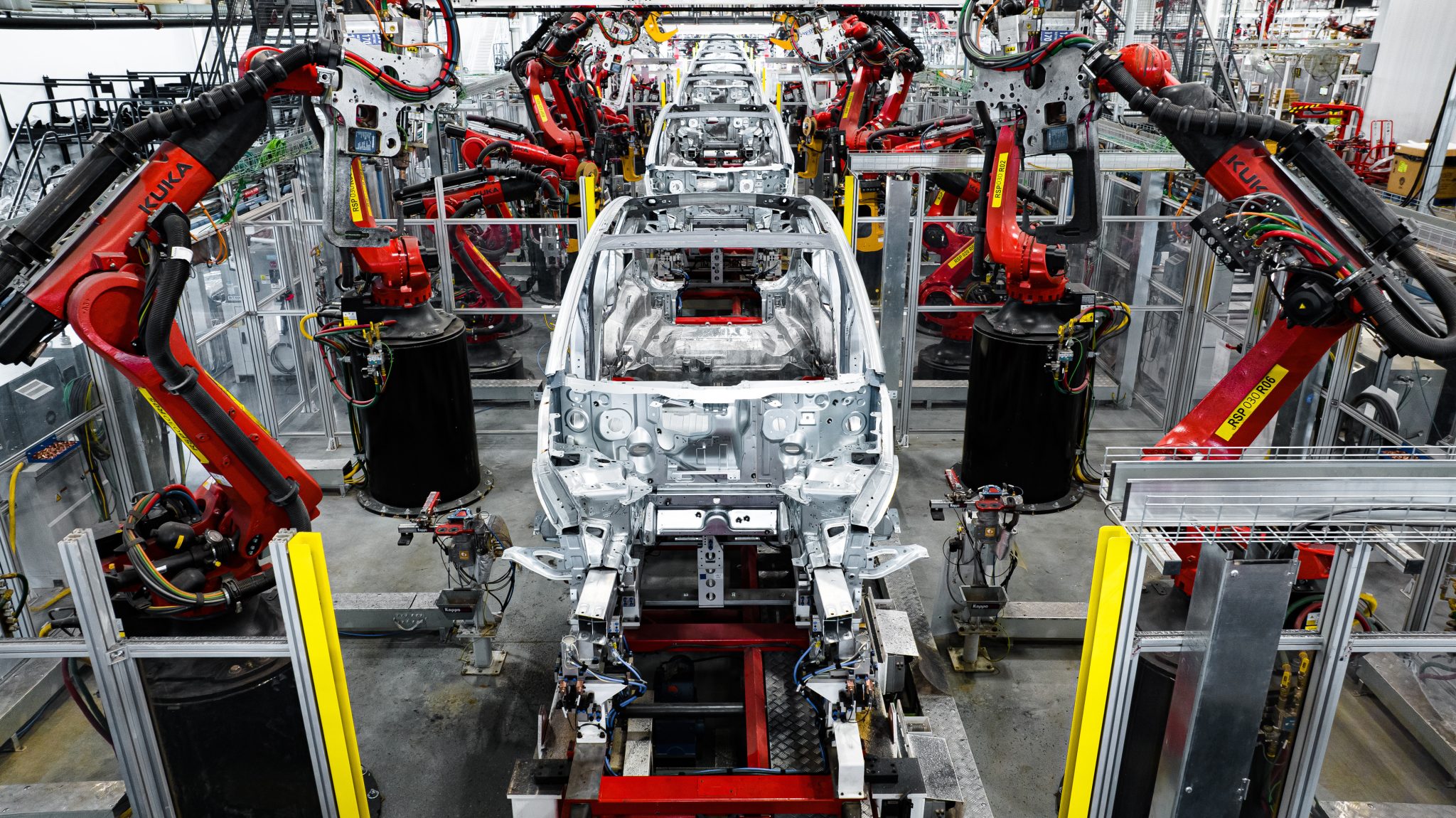

The production of the power module takes place at Vitesco Technologies’ Nuremberg facility. The company cites the presence of essential competencies and experience, along with a dedicated focus on electronics and e-mobility, as the reasons for selecting this location. Moreover, plans are in motion to transform the Nuremberg electronics plant into a “plant of the future” to ensure international competitiveness.

Vitesco Technologies has not disclosed the identity of the “major global customer” set to receive the power module from mid-2025, which is standard practice in the supplier industry.