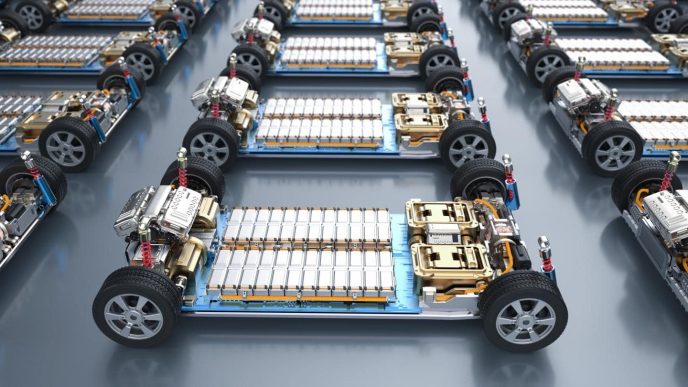

Italian automation expert Comau is taking a leading role in the European Union’s Reinforce project, a major initiative addressing the critical challenge of end-of-life management for electric vehicle (EV) batteries. The project aims to create standardized, automated, and cost-efficient processes for recycling and repurposing lithium-ion batteries while maximizing material recovery.

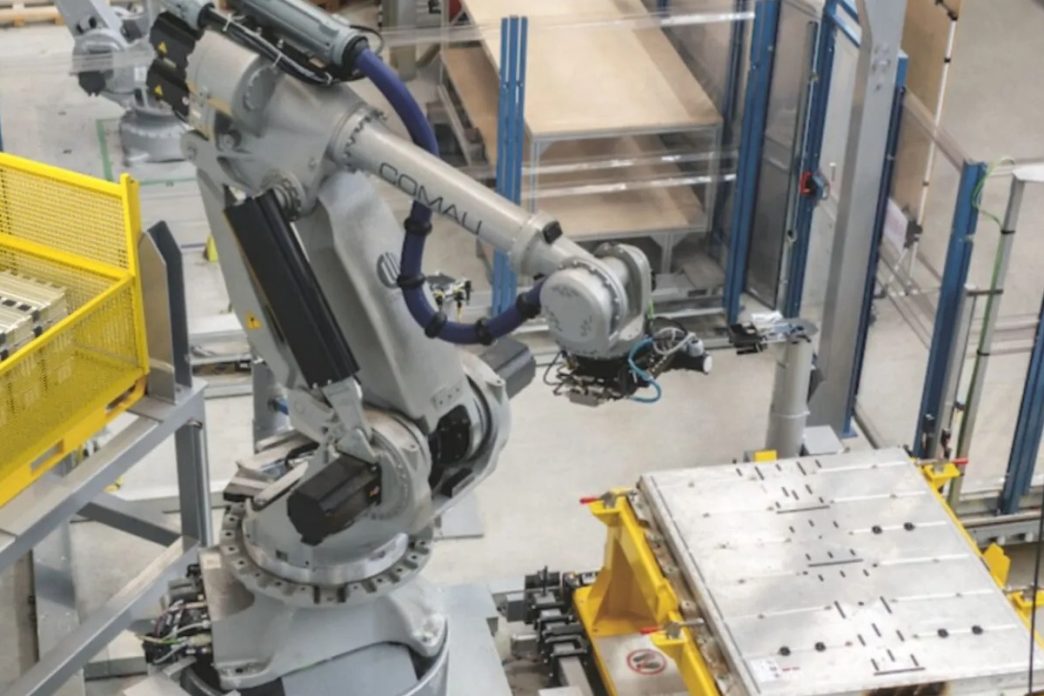

As part of its involvement, Comau is leading one of Reinforce’s eight working groups and developing a cutting-edge robotic solution for safe battery disassembly. “Our advanced robotic disassembly solution will not only enhance the efficiency and safety of the disassembly process but also support the circular economy by maximizing the recovery and reuse of materials from end-of-life batteries,” said Andrew Lloyd, Chief of Engineering at Comau.

The Reinforce project focuses on several critical areas, including optimizing battery collection routes, improving diagnostic and recovery techniques, and implementing traceable dismantling methods. Comau’s efforts aim to create a comprehensive solution that processes batteries from electric cars and stationary systems, supporting the broader goal of reducing waste and advancing sustainable electrification.

“This project underscores the increasing need to develop a circular electrification path and represents a significant step forward in sustainable battery management,” Lloyd added.

In addition to recycling, Comau is actively innovating in battery production. The company is working with the UK-based LiNa Energy to develop manufacturing processes for solid-state sodium battery cells and is a key player in the EU’s BATTwin project, which focuses on sustainable battery production.