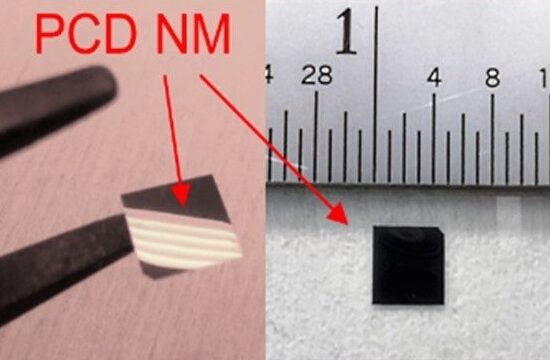

Researchers at Fraunhofer USA have achieved a significant breakthrough in electronic cooling technology by developing wafer-thin nanomembranes made of synthetic diamond. These nanomembranes can be integrated into electronic components to reduce the local heat load by up to ten times, offering a promising solution for cooling high-power-density components like those used in processors, semiconductor lasers, and electric vehicles (EVs).

The unparalleled thermal conductivity of diamond makes it ideal for cooling electronic components, improving the driving performance and service life of electric cars. Additionally, the use of diamond nanomembranes can significantly reduce the charging time of EV batteries.

See also: Researchers at Penn State University might have cracked 10-minute electric vehicle charging

Traditionally, heat sinks are made of copper or aluminium plates to increase the heat-emitting surface of components, thereby preventing damage due to overheating. The researchers’ development of nanomembranes from synthetic diamonds, thinner than a hair, allows for direct integration into components to cool power electronics in EVs. These electronics transfer traction energy from the battery to the electric motor and convert current from direct current to alternating current.

The improved heat tolerance resulting from the use of diamond nanomembranes enhances the efficiency, service life, and road performance of electric cars, while also enabling higher charging speeds. According to the researchers, “the diamond membranes contribute to charging speeds that are five times higher.”

See also: Stanford Researchers Discover Potential to Restore Capacity in Lithium Metal Batteries

The process of creating the diamond nanomembrane involves growing it on a separate silicon wafer, detaching it, turning it over, and etching away the back of the diamond layer. The final result is a free-standing, smooth diamond that can be heated at a low temperature of 80 degrees Celsius and subsequently attached to the component.

Dr. Matthias Mühle, head of the Diamond Technologies group at the Fraunhofer USA Center Midwest CMW, explained, “We want to replace this intermediate layer with our diamond nanomembrane, which is extremely effective at transferring heat to the copper, as diamond can be processed into conductive paths. As our membrane is flexible and free-standing, it can be positioned anywhere on the component or the copper or integrated directly into the cooling circuit.”