Nissan has quietly been making strides in the solid-state battery field, as the electric car industry focuses on a select few players. The automaker is confident in its progress and has begun preparations for a trial factory where the production process will be fine-tuned. This facility is expected to be operational within the next two years.

Nissan’s goal is to master large-scale manufacturing of solid-state batteries by 2026 and then increase production in the following years. The company plans to introduce an electric vehicle powered by its own solid-state battery to the market by 2028.

David Moss, Nissan’s senior vice-president for research and development in Europe, said: “We think we have something quite special and are in a group leading the technology. We want to get the cost down [compared with lithium ion batteries] by 50%, to double the energy density and to offer three times the charging speed.”

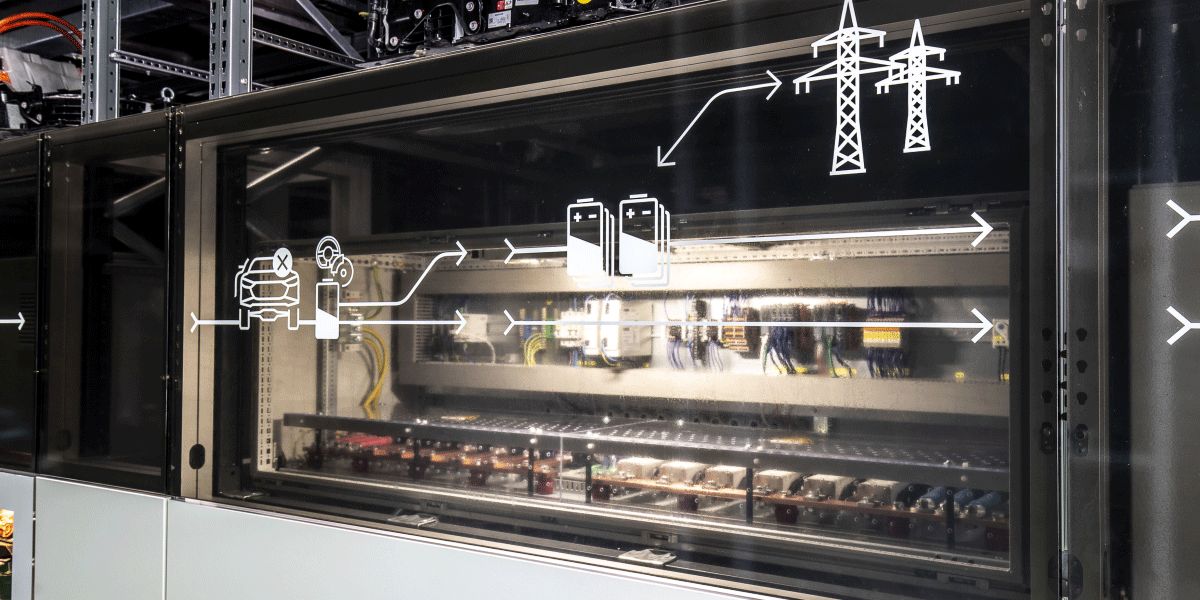

The technology is “all solid-state,” meaning it completely eliminates the use of liquid electrolytes in the battery. This is a significant improvement, as liquid electrolytes can boil, affecting the efficiency and power of the battery.

This new technology opens up the possibility of electric mobility for larger vehicles such as pick-up trucks and SUVs. However, to bring this technology to market, Nissan will need to develop an entirely new vehicle architecture and build a new factory to accommodate the changes in manufacturing. Nissan has already hinted at its plans for next-generation EV hardware with its trio of concept cars (Max-Out, Surf-Out, and Hang-Out).

Moss stated that implementing solid-state technology requires a complete overhaul of the vehicle’s design and architecture, and so it is being developed separately from any specific vehicle project to prevent delays. Fast charging speeds will also play a crucial role in reducing costs, as smaller batteries can be used if charging is faster, more stable, and consistent.