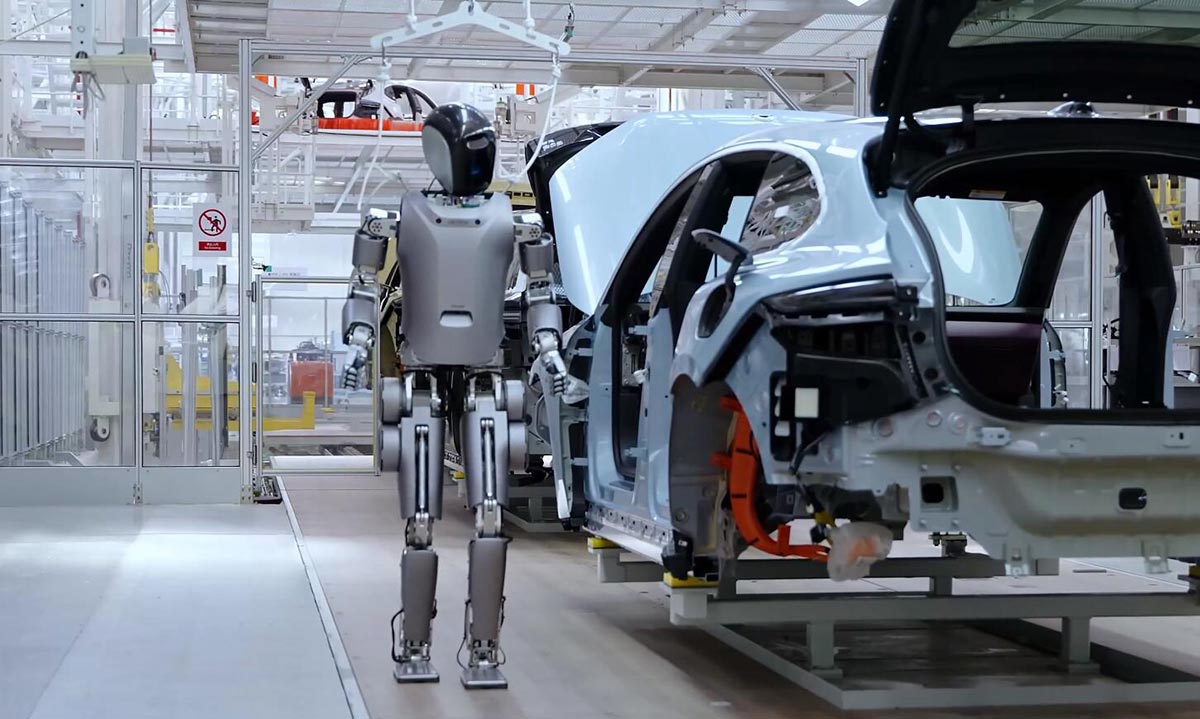

Nio has launched a pilot program utilizing humanoid robots on its EV assembly line at one of its factories.

Nio, known for manufacturing EVs at its facilities in Hefei, the largest city in Anhui Province, China, is now incorporating advanced robotics to streamline its production process.

The Shenzhen-based company UBTECH ROBOTICS, publicly traded on Hong Kong’s stock exchange, has developed the Walker S robot specifically for this purpose, marking the first instance of its use on an EV assembly line.

See also: Nio’s Sub-brand “Firefly” Makes First Appearance in Spy Shots, Set to Debut in Europe in 2025

The Walker S robot is responsible for conducting quality inspections on various components, including headlight covers, door locks, and seat belts. Additionally, it is tasked with attaching Nio EV logos to the vehicles, demonstrating its versatility and precision in assembly line tasks.

While Nio has yet to make an official statement regarding its humanoid robot pilot, UBTECH ROBOTICS is enthusiastic about the potential of deploying robots on EV assembly lines to enhance productivity. The company asserts on its website that “the future of humans lies in human-robot coexistence,” indicating a strategic focus on integrating robotics into manufacturing processes.

See also: Nio Showcases ET9’s SkyRide Chassis System in Winter Testing Video

Although specifics about the Walker S robot are not listed on UBTECH’s website, its predecessor, the Walker humanoid robot, stands at 57 inches (145 cm) tall and weighs 170 pounds (77 kg). The Walker robot is equipped with lithium iron phosphate batteries, which require two hours to charge and provide a battery life of two hours, ensuring efficient operation on the assembly line.