In a recent Twitter video shared by Shanghai’s tourism handle, Tesla’s Gigafactory Shanghai displays an awe-inspiring production speed, with a brand new Model 3 or Model Y rolling off the assembly line every 40 seconds. The plant’s efficiency and scale have once again underscored the automotive giant’s manufacturing prowess in Asia’s second-largest country.

Comparing the manufacturing capabilities, Tesla’s Gigafactory Shanghai outperforms Ford’s Dearborn, Michigan truck plant, as Tesla can produce a vehicle every 40 seconds, while Ford’s F-150 takes 49 seconds.

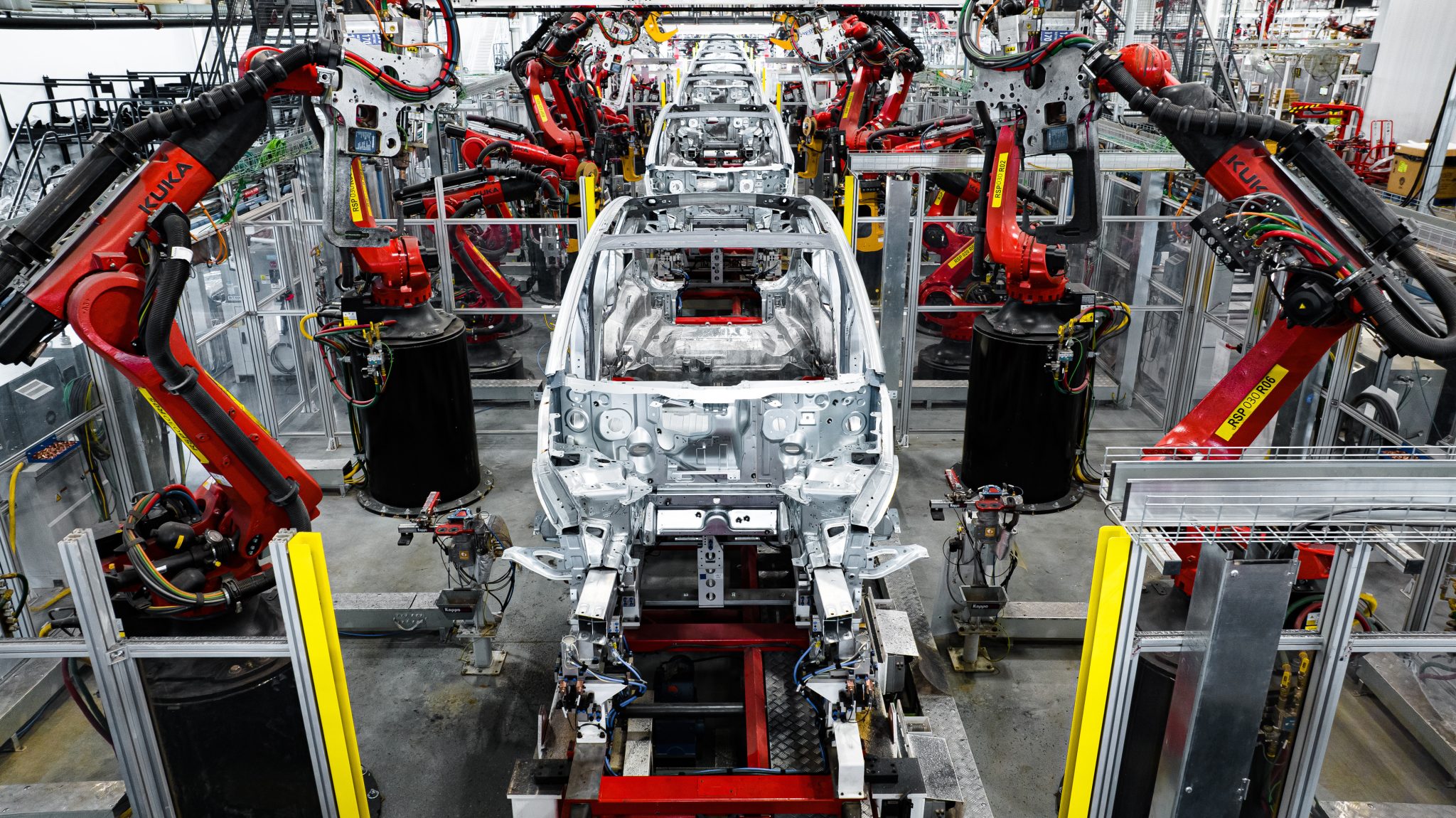

The fascinating video offers an inside glimpse of the Giga Shanghai facility, where dozens of robotic arms work in perfect harmony at a single station to enhance overall efficiency. Additionally, the clip highlights the innovative arrangement of double-stacked workshops, a technique that optimizes production lines for maximum efficiency.

Check out our efficient and eco-friendly production ♻️ and enjoy some delicious food at GFSH! 😋 https://t.co/rOKg8eoGgM

— Tesla Asia (@Tesla_Asia) July 25, 2023

Tesla’s Q1 and Q2 2023 earnings reports reveal that the Shanghai factory has been operating at near maximum capacity for several consecutive months. Despite the impressive performance, Tesla has no immediate plans to further increase production in China, as mentioned in the earnings report.

The Gigafactory Shanghai boasts an annual production capacity of over one million vehicles, contributing to the impressive sales of nearly half a million “Made-in-China” (MIC) EVs by Tesla in H1 2023. Furthermore, the facility serves as an export hub for Tesla, with the MIC Model 3 and Model Y being shipped to various overseas markets, including Thailand and Canada.

Tesla’s key to success lies in cost optimization, which involves incorporating more in-house designed controllers, utilizing cheaper and scalable drive units, and introducing undisclosed innovations to enhance efficiency further.

In an effort to simplify manufacturing, reduce component count, and lower costs, Tesla employs techniques like giga casting. Since the introduction of the IDRA giga press, several other carmakers have also announced plans to adopt this technique.

Notably, the Gigafactory Shanghai goes beyond just production; it caters to the well-being of its workers with 16 restaurants available on-site. Tesla’s IT team has developed an app called Teshenghuo, which allows workers to conveniently order food within the facility.

However, at the start of July 2023, Tesla reportedly laid off some workers from the Giga Shanghai battery production line, possibly due to the incorporation of automated equipment. In response, Tesla offered affected workers the option to transition to different workshops such as stamping, painting, or general assembly, ensuring their continued employment within the company.