Zeekr, the premium electric vehicle (EV) subsidiary of Geely Holding Group, has introduced a humanoid robot into its manufacturing process, following a similar move by Nio.

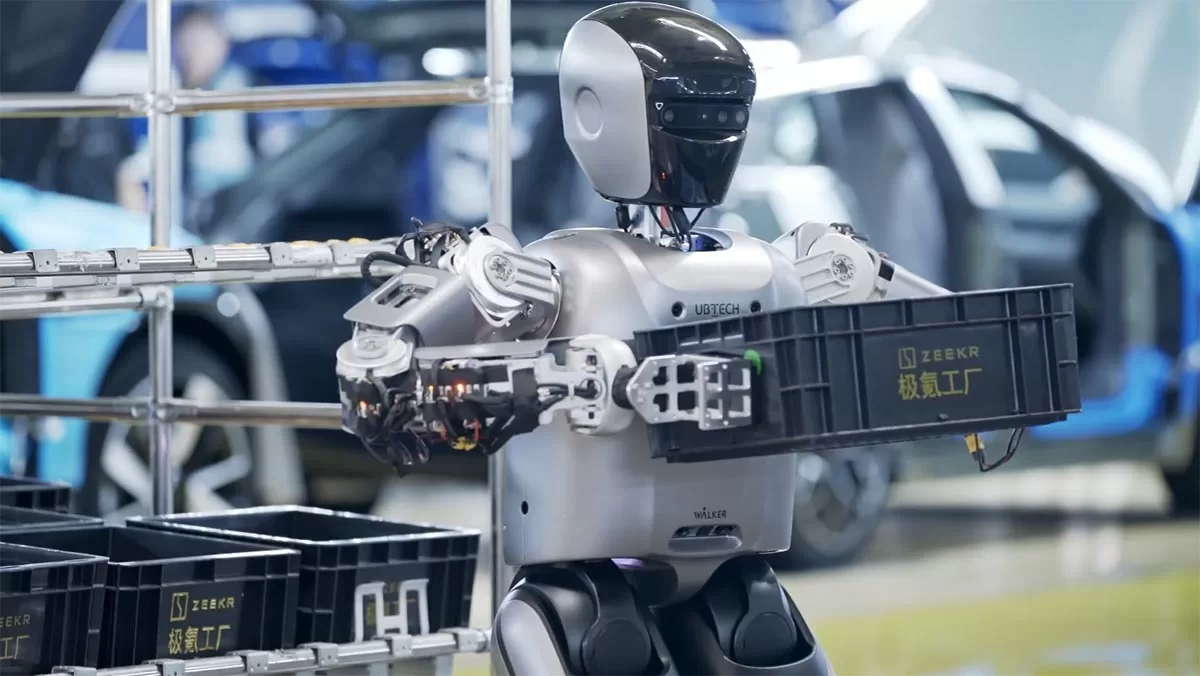

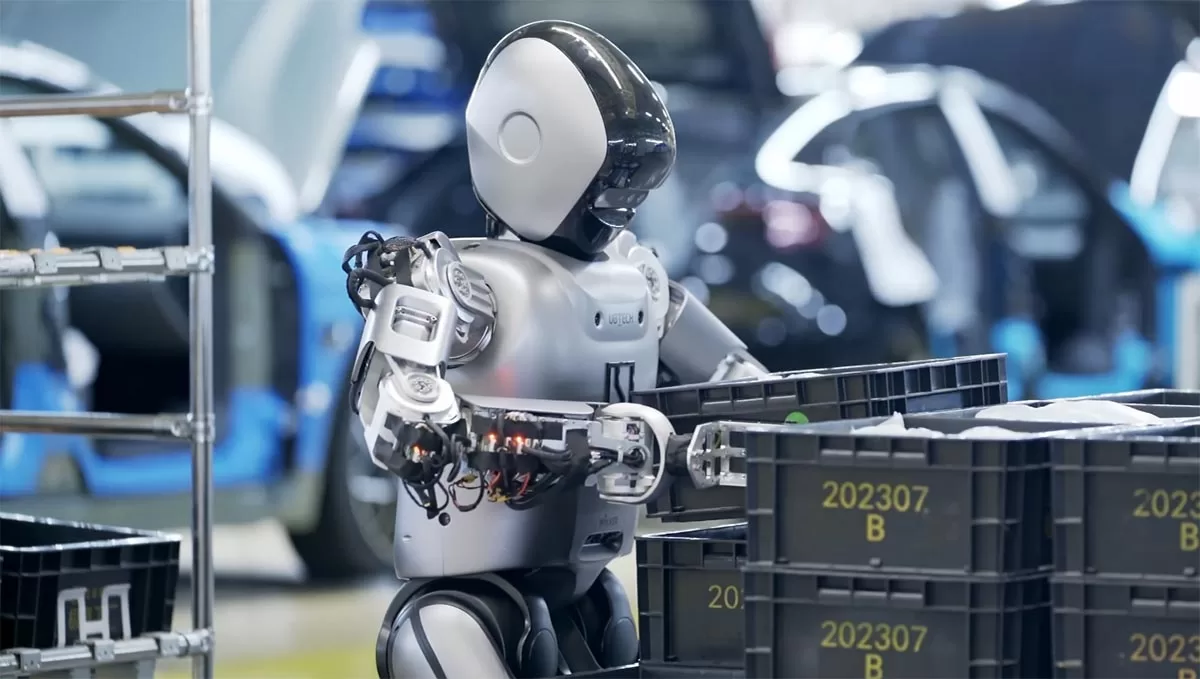

The Zeekr factory began using the Walker S Lite, a humanoid robot from UBTech Robotics, in early July. This robot has been operational at the plant for 21 days, aiding in lifting tasks and showing high efficiency in its role.

The deployment of Walker S Lite at Zeekr is part of a collaboration with UBTech, Geely Holding, and Miracle Automation Engineering. Miracle Automation, which recently secured a contract for an assembly mainline conveyor project at Nio’s F3-1 project, has been involved in similar projects with other manufacturers.

Nio Explores Integration of Humanoid Robots in Vehicle Assembly Plants

Walker S Lite is designed with advanced features, including semantic Visual Simultaneous Localization and Mapping (VSLAM) navigation, imitation learning, and visual recognition. It can autonomously navigate and perform tasks on assembly lines while interacting with automated guided vehicles (AGVs).

The robot, equipped with high-performance servo drives and force sensors, is capable of lifting boxes weighing up to 15 kilograms.

Zeekr’s initiative reflects a broader trend among electric vehicle manufacturers to integrate humanoid robots for enhanced factory automation. UBTech’s Walker S robot has also been implemented at other automotive factories, including those of Nio, Dongfeng Liuzhou Automobile, FAW-Volkswagen Qingdao, and Geely Auto, aiming to advance the use of humanoid robotics in manufacturing environments.

Dongfeng Motor Corporation Embraces Next-Generation Robotics in Vehicle Manufacturing