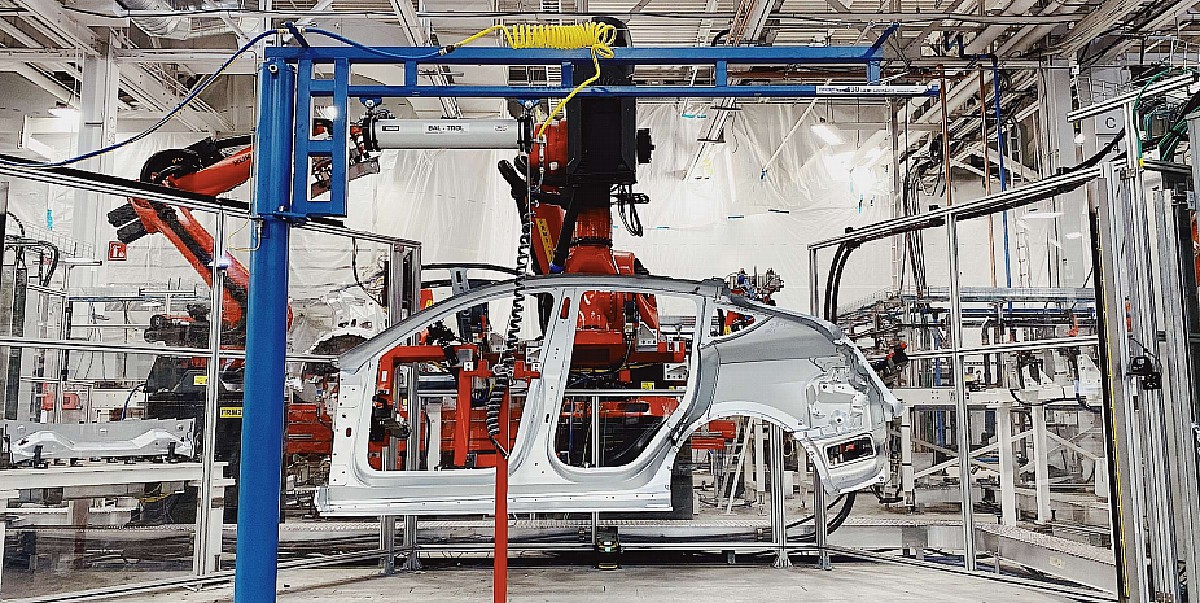

Tesla’s Giga Shanghai factory in China has made significant improvements to its production practices, enabling it to produce a Model Y body-in-white in approximately 40 seconds on average.

These upgrades to the assembly lines have allowed the automaker to speed up production, giving workers extra time off at the end of 2022. The factory uses large “Giga casting” machines and die-casting technology to streamline and accelerate body production, with the ability to even incorporate the EV’s battery pack into the vehicle’s frame.

Despite not meeting its target for 50% delivery growth from 2021 to 2022, the Giga Shanghai factory has seen impressive manufacturing growth and has set numerous records, including producing its 1 millionth Tesla EV in August 2022. The factory serves not only as a supplier for the Chinese market, but also as the company’s primary export hub.

People's Daily: Tesla Shanghai Giga factory produces a Tesla car in 40 seconds on average#tesla $TSLA pic.twitter.com/EV9bpFAfN1

— 大趙 (@zhongwen2005) January 3, 2023

Elon Musk, CEO of Tesla, has consistently emphasized the importance of manufacturing in the success of the electric vehicle company. Tesla has made significant efforts to optimize production, including reducing steps and lowering costs, which has allowed it to increase production by around 50% for the past two years.

To support these high production rates, the Giga Shanghai facility has achieved a localization rate of over 95%. This facility supplies various components for Tesla’s EVs, including batteries, chips, interiors, and advanced driver-assist systems.

Tesla is working on expanding its production capabilities with the construction of two new factories, one in Germany and the other in Texas. The company is also expected to unveil the location of a new factory in North America in the near future. In addition to these efforts, CEO Elon Musk envisions using humanoid robots developed by Tesla to make EV manufacturing even more efficient and cost-effective in the future.