Samsung is gearing up for a major shift in its production strategy as it seeks to tap into the rapidly growing market for electric vehicle components. According to the CEO of its Electro-Mechanics division, the company is preparing to pivot away from its traditional focus on smartphones and PCs and instead focus on the rising demand for automotive and automobile technologies.

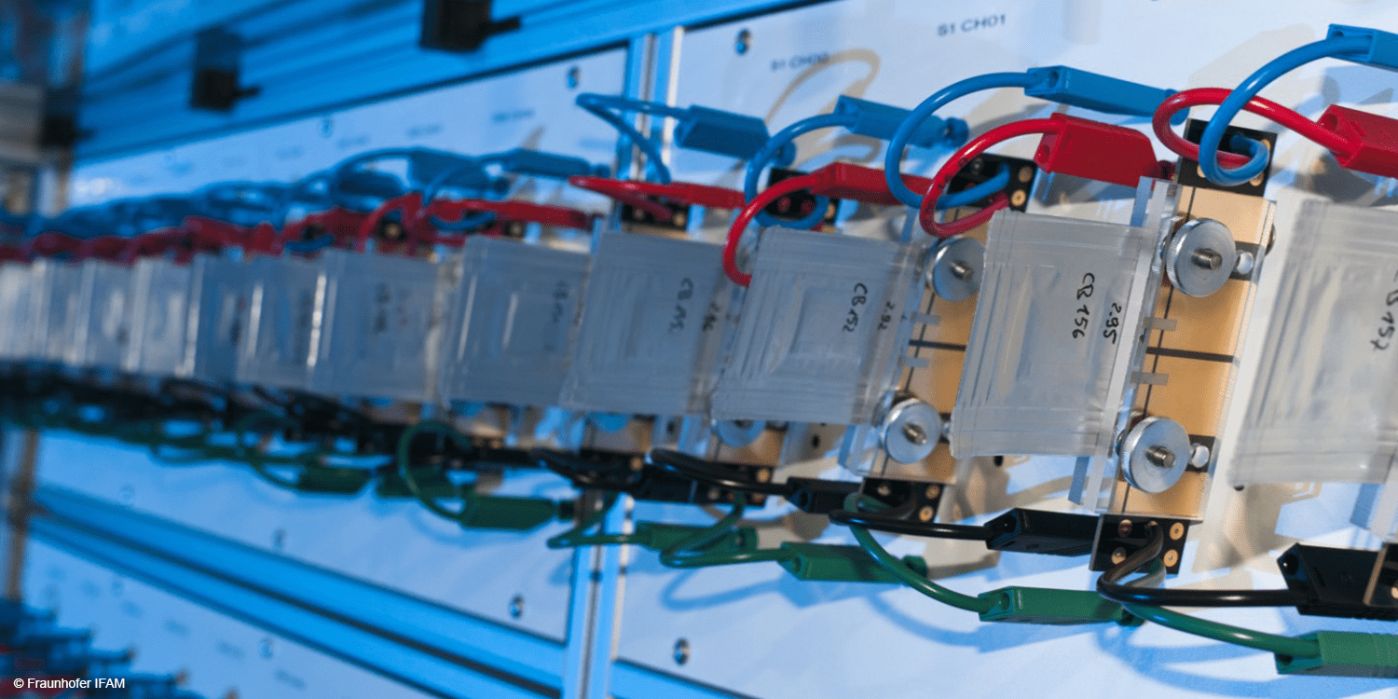

Samsung is already a major supplier of EV batteries to a number of leading automakers, including General Motors, Volkswagen, BMW, and Volvo. However, the company is now looking to vastly expand its production capacity and develop its own offerings based on new technologies like iron phosphate (LFP) or solid-state batteries.

See also: Samsung and Stellantis open up opportunities to build electric vehicle battery factories in the US

The LFP battery market is currently dominated by Chinese manufacturers like CATL and BYD, who supply cells for Tesla’s best-selling vehicles. Samsung is hoping to diversify its portfolio of performance EV batteries with LFP cells of its own, which are seen as pivotal for the next wave of mass electrification that will see many automakers introduce sub-$25,000 electric cars.

In addition to LFP and 4680-style battery technologies, Samsung is also investing in solid-state batteries. The company has reportedly equipped a pilot solid-state battery production line that will begin trial production runs in 2024. Samsung plans to leverage its experience producing solid oxide at high temperatures to create a stable oxide electrolyte that can be used in solid-state batteries instead of the flammable liquid polymer electrolyte currently used in many EV cells.

See also: General Motors and Samsung SDI to Form New Partnership for Cylindrical EV Batteries

Solid-state batteries offer several advantages over traditional lithium-ion batteries, including higher energy density and improved safety. Samsung plans to announce its solid-state battery solution once an engineering prototype is ready, with mass production set to begin in 2027.

As the deadline for commercialization of many other solid-state battery projects approaches, Samsung is hoping to establish itself as a leading supplier of EV components and capture a significant share of the growing market. With its extensive experience in developing cutting-edge technologies, the company is well-positioned to succeed in this rapidly evolving industry.