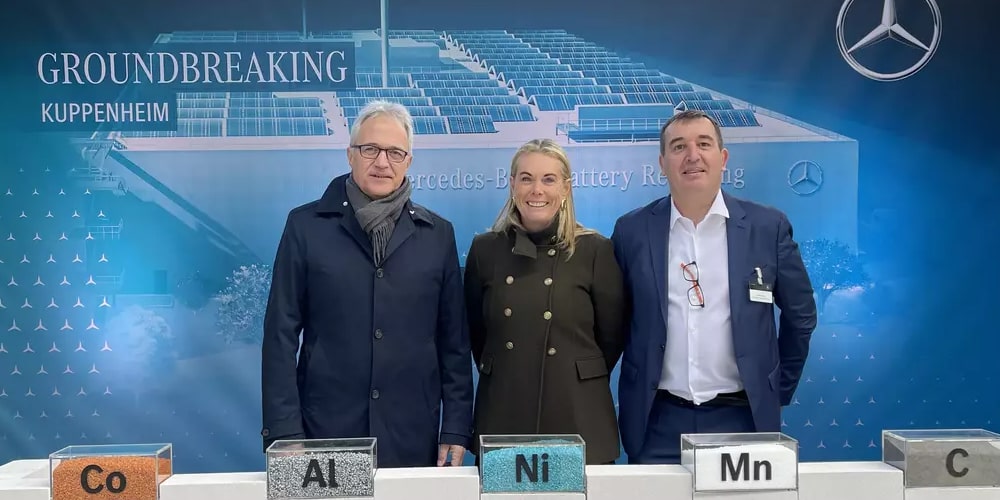

In a significant development for the battery recycling sector, Primobius, a collaborative effort between the German SMS Group and Australian battery materials firm Neometals, has secured a contract to establish a lithium-ion battery shredder plant, known as a ‘Spoke,’ at the Mercedes-Benz facility in Kuppenheim.

This deal marks Primobius’ inaugural commercial supply agreement with an international electric car manufacturer, signifying a milestone both for the joint venture and the broader cause of sustainable battery disposal. The Spoke facility is anticipated to handle a daily processing capacity of up to ten tonnes. The foundation stone laying ceremony for the battery recycling plant took place in Kuppenheim in March 2023, with the initial operational phase slated to commence by the year’s end.

Recent updates indicate a minor delay in the timeline, as stated by Neometals, the parent company of Primobius. The installation of the shredding plant is now scheduled to begin in the fourth quarter of 2023, followed by the commissioning in the first quarter of 2024.

The selection of Primobius for this project aligns with Mercedes-Benz’s strategic vision, as the automaker had designated Primobius as a partner in its global recycling strategy announcement in March 2022. The recycling plant is anticipated to boast an annual capacity of 2,500 tonnes. To meet this capacity, the facility would need to operate at full load for approximately 250 days annually, or alternatively, at a lower capacity for an extended duration.

Notably, Primobius anticipates another order from Mercedes-Benz in the near future, this time for a “hub” plant, which represents the core recycling unit. This hub plant is also designed to handle ten tonnes of material per day.

The recycling process typically involves two stages: firstly, the mechanical crushing and pre-sorting of used batteries or production rejects, which separates materials like copper and aluminium. Following this, a mixture known as the “black mass” remains, comprising battery-active materials. This initial step is often conducted near battery factories or major clients, resembling the spokes of a wheel. The subsequent transformation of the black mass into individual battery components takes place in the “hubs,” utilizing hydrometallurgical processes. These higher-cost hub plants are strategically located to process black mass from multiple spoke plants. In a departure from convention, the Mercedes-Benz pilot plant encompasses both a small spoke facility and a hub plant within Kuppenheim, a town in Baden-Württemberg, South Germany.

This partnership between Primobius and Mercedes-Benz exemplifies a proactive stride towards establishing a sustainable and environmentally responsible ecosystem for managing lithium-ion batteries, a crucial step as the electric vehicle market continues to expand.