Our Next Energy (ONE), a promising energy storage technology startup based in Michigan, has unveiled impressive advancements in its Aries II lithium iron phosphate (LFP) battery pack. This breakthrough places the battery in close competition with the benchmark nickel cobalt manganese (NCM) packs commonly employed in electric passenger vehicles.

The company asserts that its Aries II battery has effectively bridged the gap in both range and mass, achieving a remarkable proximity of just six percent difference when compared to the leading NCM battery packs frequently chosen by automakers for their electric vehicles (EVs).

For the LFP battery technology, attaining near-energy density parity with the NCM standard marks a significant milestone. Currently, the majority of electric vehicles sold in the United States rely on NCM batteries due to their superior energy density at the cellular level in contrast to LFP alternatives. This preference stems from automakers’ inclination toward NCM batteries for long-range EVs.

However, ONE’s Aries II battery might prove to be a game-changer in this landscape due to its unique advantages. The battery’s cost is approximately 25 percent lower compared to a comparable NCM battery. This cost reduction is attributed to the absence of nickel and cobalt in its composition. Additionally, the Aries II battery addresses safety concerns by minimizing the risk of thermal runaway, a potential danger in batteries, as it avoids self-oxidation during instances of cell crushing or short-circuiting.

Mujeeb Ijaz, CEO and founder of ONE, highlighted, “LFP batteries have many advantages over NCM batteries, including cost and durability, while using safer and more abundant materials. The key shortfall has been range and energy density. By engineering a battery pack with similar energy density to NCM, ONE has made LFP a sustainable alternative.”

Since its inception in July 2020, ONE has remained dedicated to bridging the energy density gap between LFP and NCM batteries. The company not only successfully closed the gap but also achieved a remarkable energy density increase of 20-30 percent when compared to conventional LFP battery systems. The Aries II battery boasts an energy density of 263 Wh/L and 162 Wh/kg, indicating a substantial 34 percent and 23 percent improvement over the leading LFP pack benchmark.

Chris Hughes, Chief Battery Engineer at ONE, elaborated on the challenges the team overcame, stating, “When the team took on the challenge of achieving energy parity with NCM batteries, we looked at everything from improving cell chemistry to redesigning the inside of the pack. Ultimately, it was the durability and safety of LFP that led to our novel pack and cell design that boosted Aries II’s energy density.”

ONE’s engineering team also made remarkable strides in reducing the overall pack weight. By employing more abundant and cost-effective raw materials at the cell level, the company could incorporate advanced materials in the pack, consequently reducing its overall weight. This combination of heightened energy density and lightweight design enables the Aries II battery to provide an impressive range of over 350 miles for a standard passenger electric vehicle.

A noteworthy advantage of LFP batteries lies in their supply chain sustainability. The Aries II battery capitalizes on the earth’s abundant five percent iron composition, a stark contrast to the less than 0.1 percent makeup of nickel and cobalt.

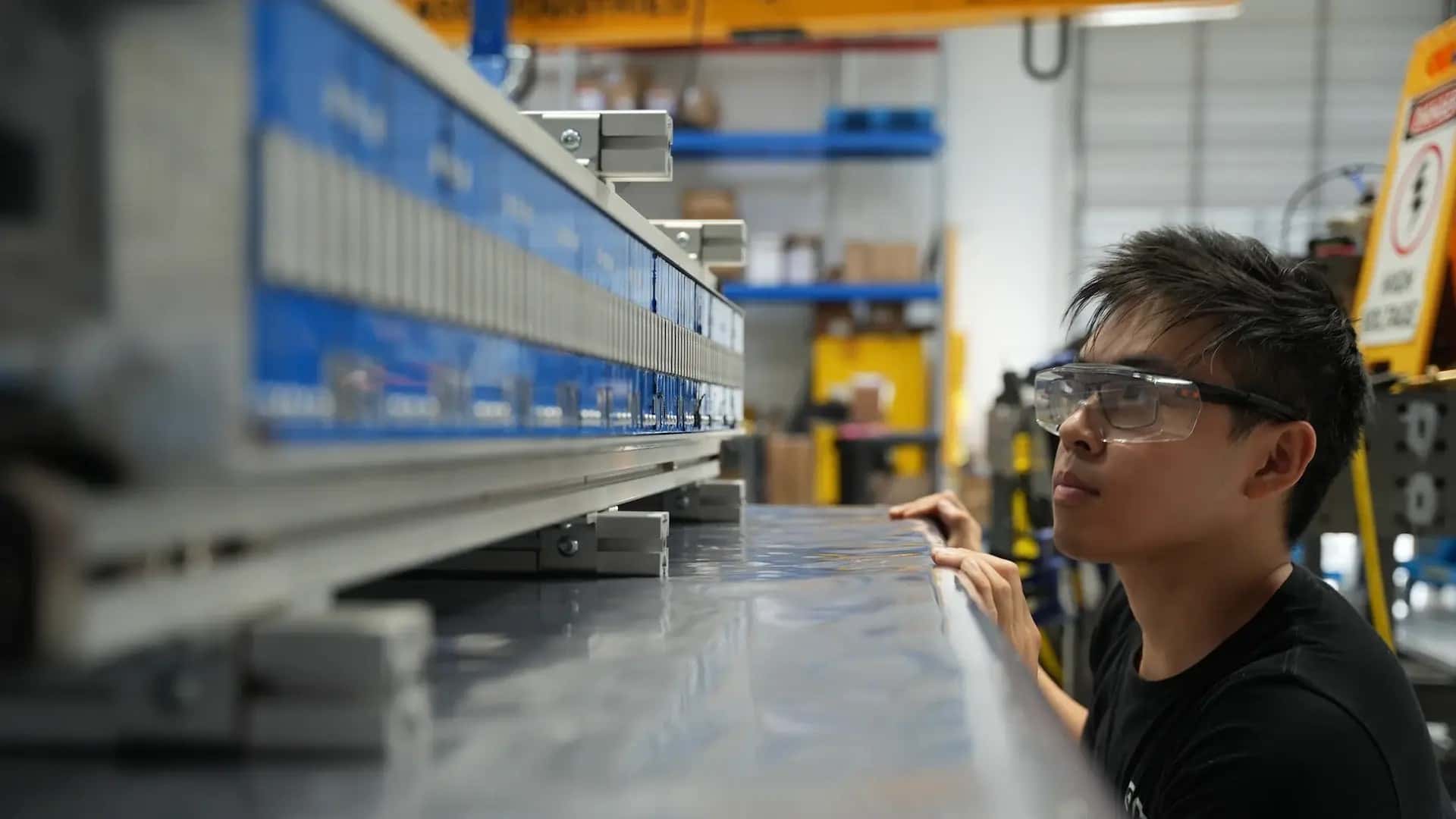

ONE anticipates full compliance of its Aries II batteries with the Inflation Reduction Act (IRA) requirements as it prepares for production commencement in late 2024 at the ONE Circle facility situated in Van Buren Township, Michigan. With these advancements, ONE is poised to potentially reshape the EV battery market, offering a compelling and sustainable alternative to the prevailing NCM battery solutions.