BYD and FAW have achieved a significant breakthrough in the electric mobility sector by producing their inaugural battery pack at their state-of-the-art factory in Changchun, the capital of Jilin province in northeast China. The new plant, a joint venture named FAW FinDreams New Energy Technology, represents a major collaboration between the two giants in the automobile industry. However, full-scale production is set to commence in September 2023.

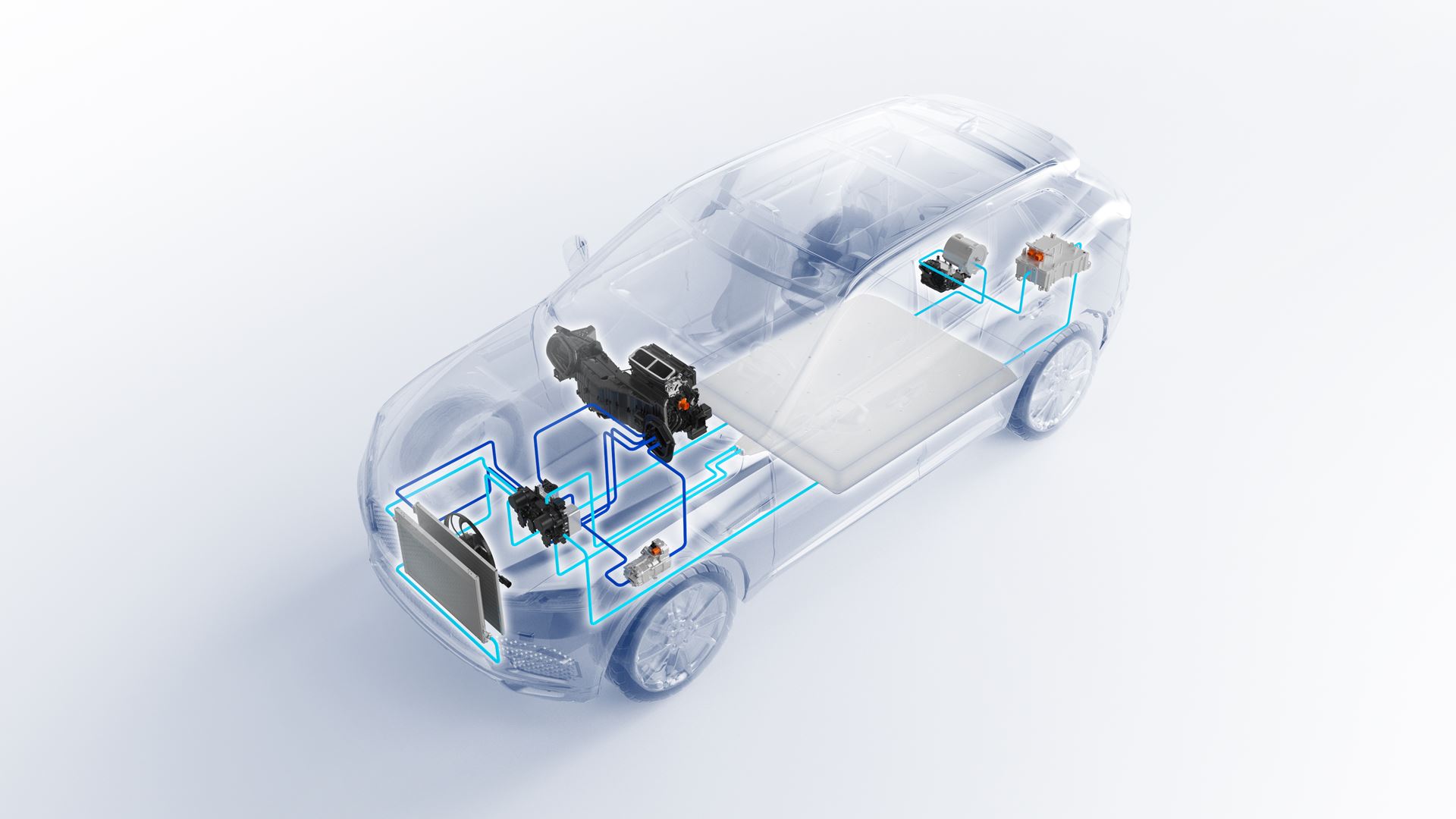

The construction of this ambitious production facility began in February 2022, with an ambitious goal to reach an impressive annual capacity of 45 GWh. The factory aims to specialize in the manufacturing of blade batteries, a pioneering technology developed in-house by BYD. These innovative pouch cells, distinguished by their elongated shape resembling a sword blade, are exclusively crafted with LFP chemistry.

See also: BYD debuted its bus chassis technology platform using Blade Battery

Commenting on this crucial milestone, BYD stated, “The production of the first battery pack at the plant marks a significant tuning of the production line, setting the groundwork for full-fledged production in September,” as reported by Chinese media.

Upon reaching the target capacity of 45 GWh, the factory is poised to become a formidable force, with the capability to produce batteries for up to one million electric vehicles annually. This impressive production output would be achievable with 45 kWh batteries per vehicle. However, for larger batteries, it may not suffice to meet the demand. Nonetheless, the factory’s projected annual production value of 20 billion yuan (approximately 2.5 billion euros) highlights its immense potential and growth prospects.

To facilitate their ambitious venture, BYD aims to maintain a competitive price point of 444 yuan per kWh (roughly 55 euros per kilowatt-hour) for their blade batteries, signaling a commitment to making electric vehicles more accessible to the mass market.

While FAW FinDreams, also known as FAW Fudi in China, has already integrated BYD’s blade batteries into the Hongqi E-QM5, their future plans for deploying these cutting-edge batteries in other vehicles remain undisclosed. It remains to be seen if FAW and BYD will primarily utilize the joint plant’s output or extend their supply to third-party customers.

With the first battery pack off the assembly line, both companies are eagerly looking forward to scaling up production and setting new benchmarks in the electric vehicle industry. As the world embraces sustainable transportation solutions, BYD and FAW are poised to play a leading role in driving the adoption of eMobility components with their revolutionary blade batteries.