German automotive technology giant, Bosch, has recently expanded its eMobility offerings with the introduction of 800-volt systems. The company has commenced the serial production of an electric drive and an inverter featuring 800-volt technology. These components are not only lauded for their performance, but also for their remarkable efficiency.

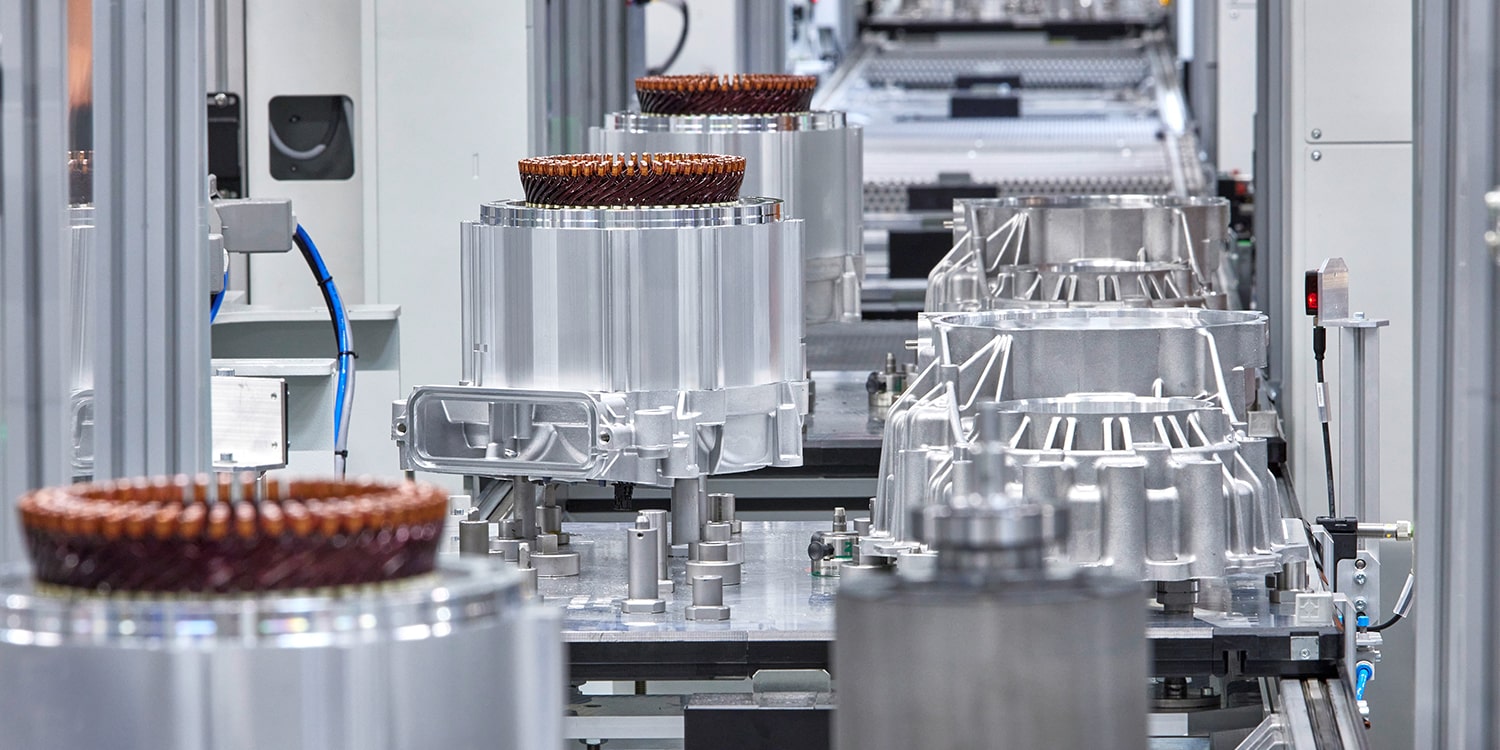

The 800-volt variant of the electric motor, utilizing a permanent magnet synchronous motor design, boasts an impressive power output of 460 kW and a torque of 830 Nm. Bosch leverages a unique ‘iPIN’ bar winding technology to enhance the motor’s efficiency, compactness, and automation during production. This innovation employs copper rods instead of traditional wound copper wire, thereby increasing the copper filling level within the stator.

See also: Bosch Seeks U.S. Government Subsidies to Power Ambitious Electric Vehicle Chip Plant Expansion

Bosch highlights that this advancement results in a power density of 60 kilowatts per kilogram—a substantial 35% increase in comparison to conventional setups. The torque density is equally noteworthy at 105 Newton metres per kilogram. With peak efficiency reaching up to 98%, the Bosch motor demonstrates remarkable energy utilization.

Notably, Bosch introduces the active components of this drive—the rotor and stator—as a first for a German premium automaker. Although Bosch refrains from specifying the automaker, it is worth mentioning that manufacturers such as BMW (with the New Class models), Audi, and Porsche (utilizing the PPE platform) have adopted the 800-volt system. Mercedes, on the other hand, is anticipated to transition to 800 volts for the EVA-2 platform, featuring their proprietary eATS-2.0 drive unit.

The company’s plans include the incorporation of oil cooling in the next iteration of the 800-volt motor. This development aims to enhance heat dissipation and ensure consistent performance during extended journeys or in commercial vehicle applications.

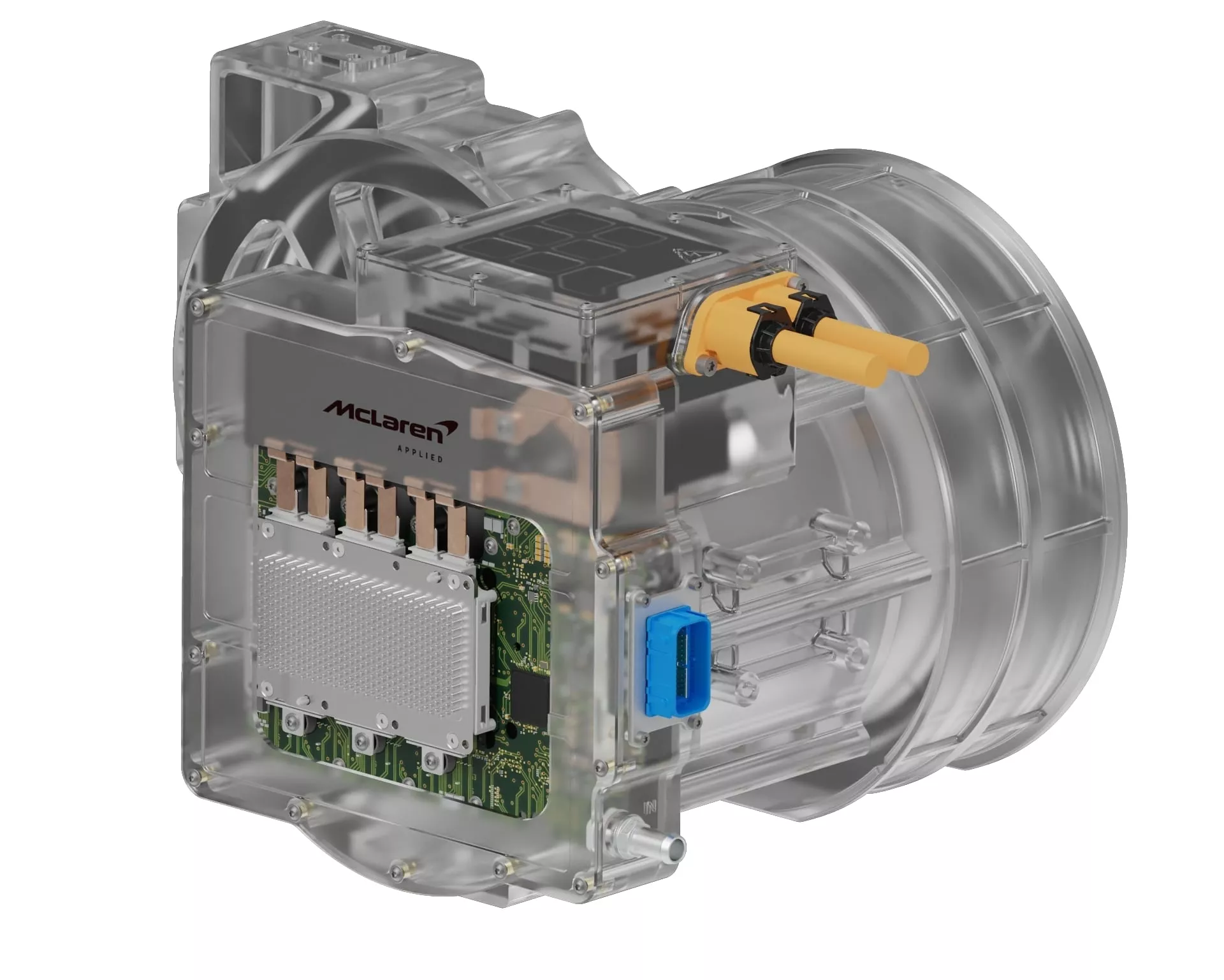

Moreover, Bosch’s 800-volt inverter relies on silicon carbide (SiC) semiconductors, contributing to improved efficiency and extended range. This integration of SiC chips elevates inverter efficiency to an impressive 99%, according to Bosch. The higher voltage level also enables a more compact inverter design, thanks to the implementation of lighter and thinner cables that can handle the increased power load at elevated voltages.

See also: Seres and Bosch China Forge Strategic Alliance for Electric Vehicle Advancements

Ralf Schmid, Divisional Board Member responsible for electrification in Bosch Powertrain Solutions, stated, “Bosch is advancing the voltage frontier in electromobility. Our 800-volt technology signifies a significant stride towards more potent electric powertrains and reduced recharging durations.” This move from Bosch showcases a pivotal progression in the realm of electric mobility and highlights the company’s commitment to pushing the boundaries of innovation in the automotive sector.