Researchers at the U.S. Department of Energy’s Argonne National Laboratory have unveiled a new cathode design for lithium-ion batteries, potentially improving their performance and reducing production costs. This innovation builds on a previously developed NMC (Nickel Manganese Cobalt) material, but with a key modification: the surface of the cathode is now enriched with cobalt, while the interior remains virtually cobalt-free. As a result, the use of cobalt has been significantly reduced, comprising only about two percent of the material compared to the typical ten to twenty percent.

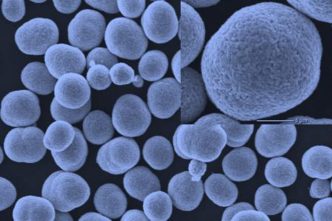

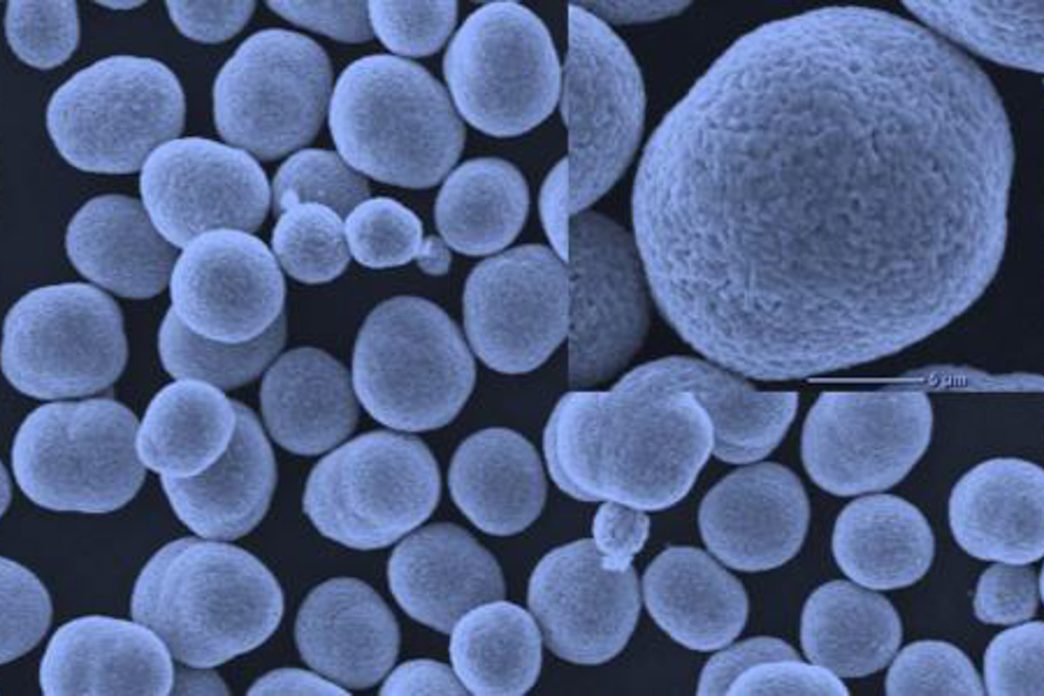

The new cathode design, known as the ‘dual-gradient’ structure, incorporates a composition gradient approach where the concentration of nickel decreases from the core to the surface of the cathode particles. This modification aims to maximize energy density during high-voltage battery operation, while minimizing reactivity, the laboratory explained. These cathode particles feature a layered structure, creating pathways that facilitate the transport of lithium ions between the battery’s electrodes.

“This new design could help batteries operate at higher voltages, increasing energy output and extending driving ranges for electric vehicles (EVs),” said Khalil Amine, head of the Advanced Battery Technology team at Argonne. “At the same time, they must remain safe and be less expensive to produce.”

The introduction of the dual-gradient design addresses a significant challenge with cathodes in high-voltage applications: the risk of structural breakdown and increased reactivity with the battery’s electrolyte. To counteract this, the particles’ surface is deliberately disordered, which suppresses crack formation and reactivity, while the ordered core promotes efficient ion transport.

Tests on the new material have shown promising results. After 500 charge and discharge cycles, the cathode material retained 98 percent of its original capacity, confirming its stability under high-voltage conditions. “We proved that the disordered particle surface is indestructible, with virtually no reactivity or structural strain,” said Tongchao Liu, a chemist at Argonne and lead author of a recent article in Nature Energy on the dual-gradient cathode design.

The new cathode material has already been licensed to battery and material manufacturers and is expected to be used commercially.

Source: anl.gov