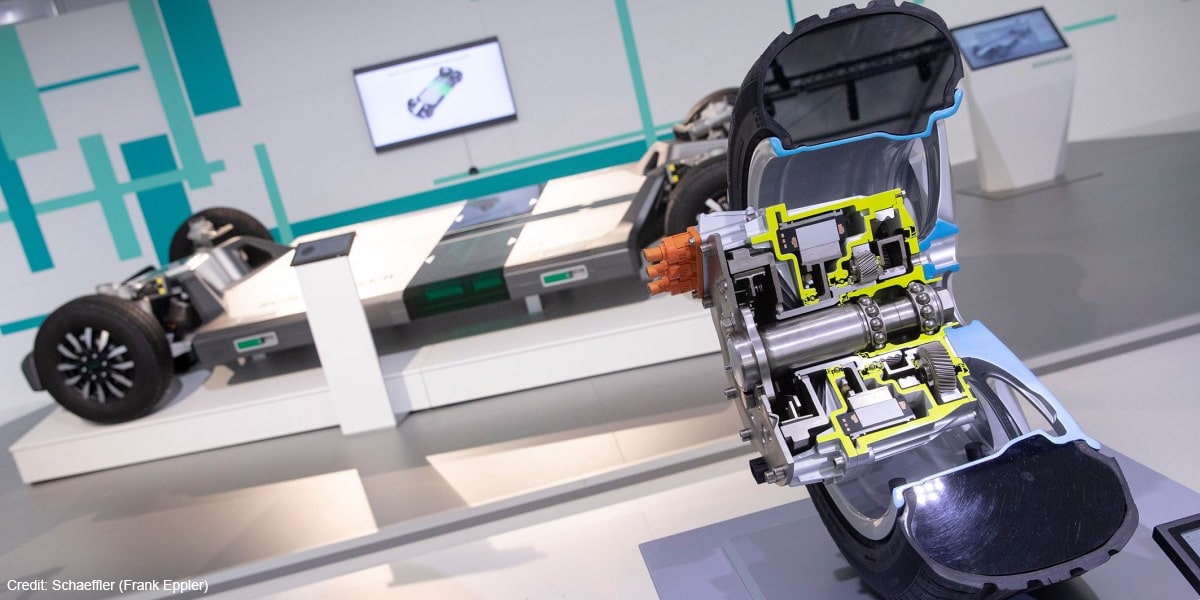

German automotive supplier Schaeffler has announced that it will soon begin series production of its in-wheel electric drive for three customers who manufacture compact municipal vehicles. The new drive technology, which features all necessary components installed directly in the wheel rim, is designed to make vehicles more agile and easier to manoeuvre in urban traffic while freeing up space that can be used for additional batteries or storage.

Speaking about the new drive technology, Matthias Zink, CEO of Schaeffler Automotive OEM, said: “We are excited to introduce our innovative in-wheel electric drive to the market. This technology is a game-changer for the urban mobility industry, offering improved handling, enhanced safety, and increased efficiency.”

The drive unit comprises an electric motor, a gearbox, and a mechanical friction brake, all of which are integrated into a 14-inch (or larger) rim. The inverter, however, must still be placed in the vehicle, but it can be positioned flexibly and does not necessarily have to be in the drive axle. Schaeffler is currently developing drive systems for 48 to 400 volts, with higher voltages also possible in the future.

See also: Hyundai Mobis Develops Electric In-Wheel System for Direct Motor Control of Each Wheel

One of the vehicles that will feature Schaeffler’s in-wheel electric drive is a multifunction vehicle with wheel hub drive from Jungo. Nicolas Jungo, the company’s founder and CEO, said: “The electric in-wheel motors and braking technology eliminates the need for oil changes and greatly enhances our vehicles’ performance in terms of efficiency, power-to-weight ratio, safety, handling, and braking reliability.”

Schaeffler’s new drive technology is primarily aimed at mobile work machines that are used in inner cities. In such vehicles, the disadvantages of wheel hub motors are negligible. While the wheel hub drive may make handling more difficult at higher speeds or during dynamic driving, refuse collection vehicles, snow ploughs, or light vans tend to travel at lower speeds in the city.

With the new drive technology, Schaeffler is tapping into a new and steadily growing market and intends to equip more and more work vehicles for cities and municipalities, in factory and logistics yards, at ports, in large parking lots, and airports with the wheel hub drive in the future. Vehicle operators of the vehicles will also benefit from the fact that the wheel hub motors have long-life, low-maintenance wheel bearings and gearboxes, meaning less maintenance and lower operating costs.

See also: Audi launched charging hub with and exclusive lounge and 320 kW chargers

In summary, Schaeffler’s new in-wheel electric drive is set to revolutionize the urban mobility industry by offering improved handling, enhanced safety, and increased efficiency. With a focus on mobile work machines that are used in inner cities, Schaeffler is tapping into a new and steadily growing market, and its innovative drive technology is sure to be in high demand among vehicle operators who are looking for long-life, low-maintenance solutions that can help reduce operating costs.