ZSW, the Centre for Solar Energy and Hydrogen Research in Baden-Württemberg, has made a groundbreaking discovery in the production of cathodes for lithium-ion batteries. The researchers have replaced toxic solvents with water in the production process, making it a safer, more environmentally-friendly and cheaper process.

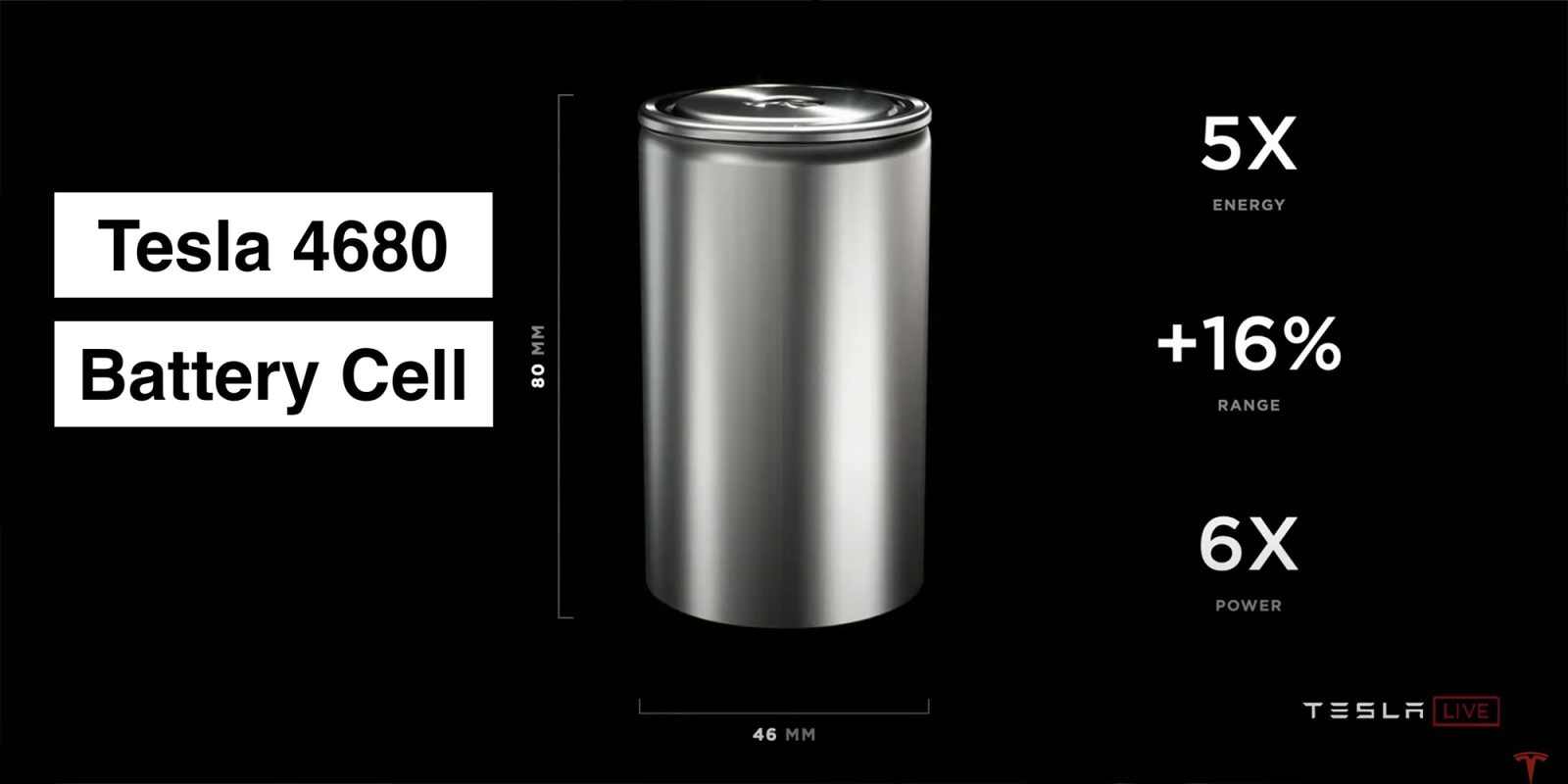

Lithium-ion batteries, which are used in electric vehicles, rely on materials with a high proportion of nickel in the cathode mass to increase their energy density. However, the production of these cathodes requires toxic solvents and chemicals, which can have a negative impact on both the environment and human health. The use of water and aqueous liquids instead of these solvents is a significant breakthrough that has the potential to revolutionize the production of lithium-ion batteries.

See also: Electric Vehicles Linked to Improved Health: Study Finds Surprising Benefits of Zero-Emissions Cars

Dr Margret Wohlfarth-Mehrens, who led the project, explained that the team was inspired by their previous success in using water as a solvent for the anodes. “After working with water as a solvent for the anodes for many years, also on an industrial scale, we have now managed to do the same for the cathode materials,” she said. “In addition to eliminating toxic solvents, the use of water also makes it possible to use non-fluorinated binders, which significantly simplifies the recycling of batteries.”

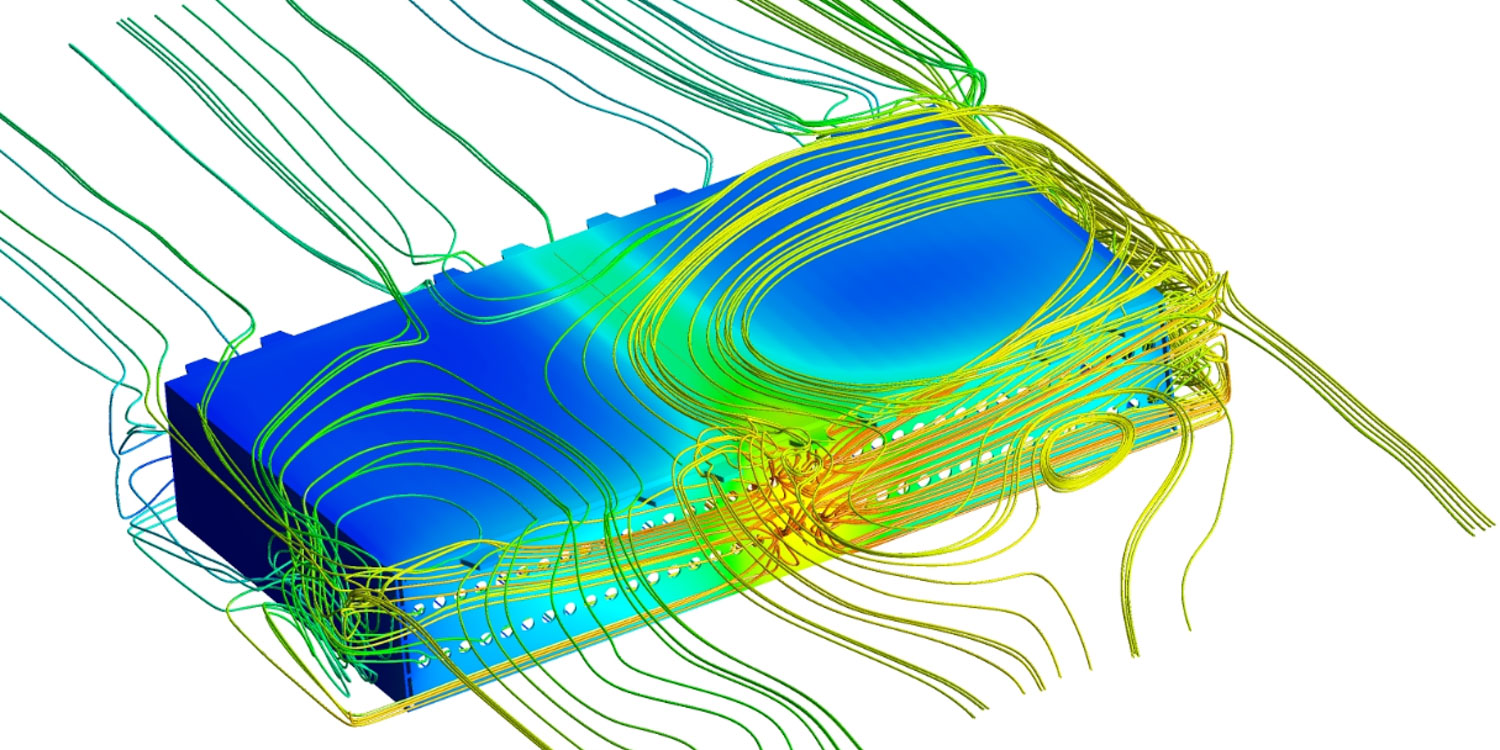

The team has successfully produced electrodes on a millimeter scale in the laboratory and, more recently, electrodes of around 100 meters in length on a scale close to production, without using solvents. The electrodes have been installed in round cells of the 21700 type, which are used in the Tesla Model 3, and have demonstrated promising results. “After 1,000 charge/discharge cycles, they still had 80 per cent of the initial capacity and are thus suitable for use in battery vehicles,” the research institute stated.

The discovery not only improves the sustainability of the battery production process, but it is also cheaper. However, the ZSW did not provide any further details on the cost reduction. The process is expected to be tested for other cell formats in the near future.

Prof. Dr Markus Hölzle, head of the ZSW business unit in Ulm, expressed his satisfaction with the discovery. “Our work aims to improve the production of electrodes in lithium-ion batteries and make it environmentally friendly without compromising battery performance,” he said. “The substitution of toxic solvents and non-biodegradable fluorine-containing chemicals plays an important role in this.”

This breakthrough discovery in battery production is expected to have far-reaching implications for the electric vehicle industry and the wider renewable energy sector.