Toshiba has unveiled a direct recycling method for lithium-ion batteries featuring oxide anodes, employing a simple heat treatment process that preserves the material’s stability. The new technique, which aims to address sustainability concerns in response to the EU Battery Regulation that came into effect in August 2023, allows for the recycling of high-power, long-life oxide anode lithium-ion batteries without the need for complex reactivation procedures.

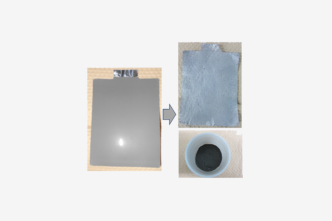

In a press release, Toshiba outlined the advantages of this new recycling process, stating, “We developed a direct recycling method that enables the recycling of high-power, long-life oxide anode lithium-ion batteries through a simple heat treatment process, and has demonstrated the effectiveness of this method.” By utilizing the inherent stability of the oxide active material’s crystal structure, the process separates the active material from the negative electrode foil, making it reusable at a low cost.

The company has successfully applied the method to niobium-titanium oxide anode batteries. Performance tests of recycled electrodes revealed they retained over 97% of their original capacity, with the recycled batteries demonstrating similar longevity to new ones. Toshiba’s recycling breakthrough presents a significant step forward in enhancing battery sustainability, with potential implications for the broader electric vehicle and energy storage markets.

This marks Toshiba’s first significant venture into battery recycling, though the company remains deeply involved in battery production and technology. In addition to this innovation, Toshiba has recently ventured into battery swapping technology and announced a design partnership with Airbus for hydrogen aircraft development.