Tesla is moving forward with the production of 4680-format battery cells at its Texas plant, with the company making an improved version of the cylindrical cell already. The company is also set to make its cathode material in Austin before the end of the year. Drew Baglino, a high-ranking manager at Tesla, revealed during a conference call that the company will make the first generation tabless cell in Texas and a “second mote manufacturable one.” The 4680 cylindrical cells, unveiled at Tesla’s Battery Day in 2020, will significantly reduce battery costs by up to 50% due to several innovations. However, the company encountered some difficulties on the way to bringing the cylindrical cell and announced improvements into series production.

See also: Tesla plans to start production of 4680-format battery cells at the Texas Gigafactory this quarter

According to Baglino, Tesla has established a cost-down roadmap through 2026, dividing it into five areas: the tabless cell design itself, the anode and cathode materials, the structural pack concept, and the cell factory itself. Baglino added that Tesla has made progress across all these aspects since then.

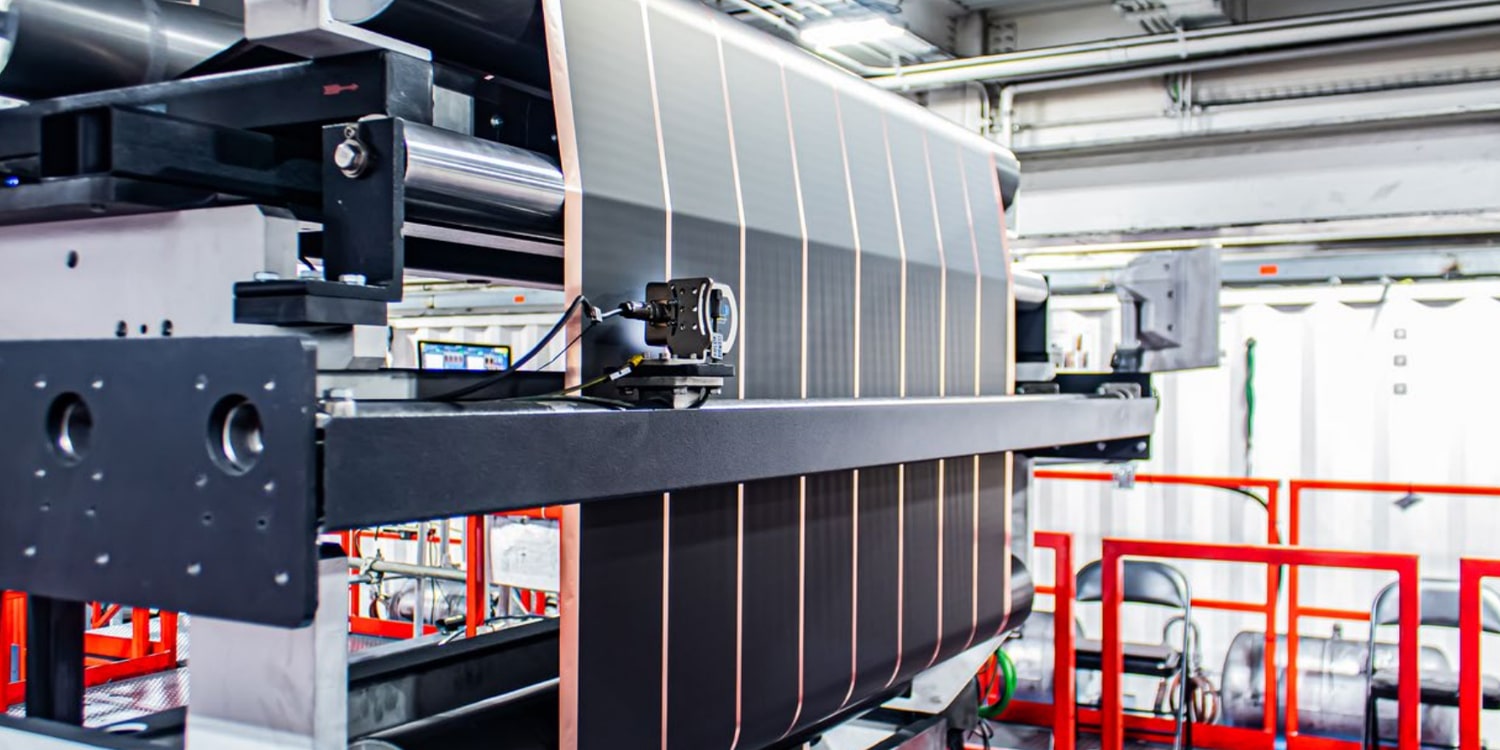

Once fully ramped up, the 4680 cell factory in Texas is expected to have a 70% lower capex per GWh “than typical cell factories.” Tesla had reached a weekly production rate of 868,000 4680 cells in December 2022, enough for 1,000 vehicles. The first cathode material for the 4680 cells will also be produced in Texas this year. Half of the production equipment and three-quarters of the supply units have already been installed in the cathode building in Austin.

Tesla is also planning to build its own lithium refinery in Texas, with construction set to begin in May. Baglino confirmed that the refinery uses the sulphate-free refining process with reduced process costs, no acid or caustic reagents, and lower embodied energy. It also produces a beneficial byproduct that can be repurposed in construction materials.

On the roadmap, there should also be progress on the structural battery pack. Baglino stated that the company believes structural, as a concept, is a good one, and that they will continue to structurally load the cells and use the pack as the floor of the vehicle while iterating the design to closer to B-level execution of this A-level architecture in future programs. The Model Y and other models could see more advanced versions of the structural packs. In conclusion, Tesla is making significant strides in the production of the 4680-format battery cells, which could result in more affordable electric vehicles and a more sustainable future.