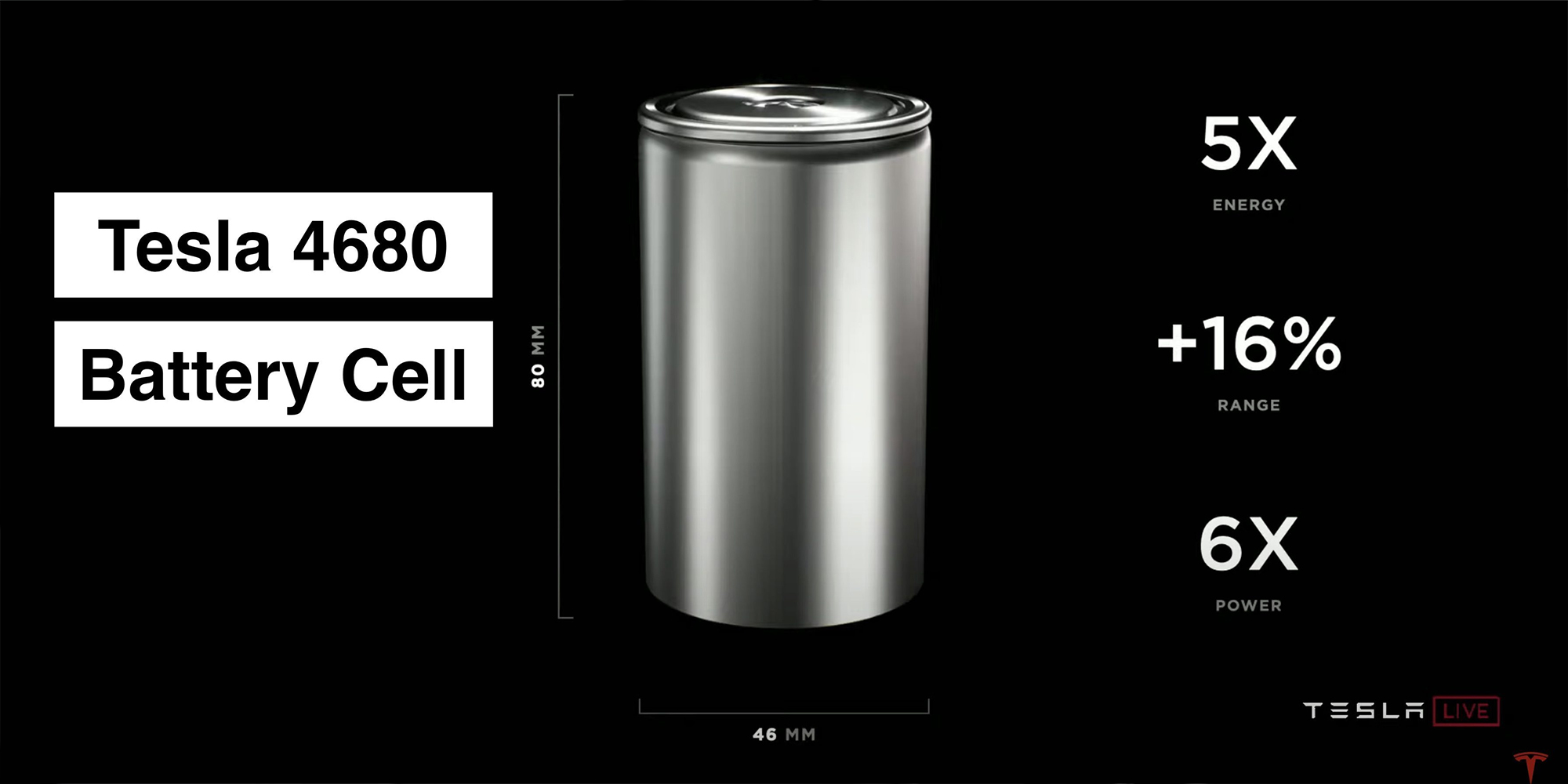

Tesla has provided a comprehensive update on its 4680 battery cell program, which is anticipated to be critical for its future electric vehicles. The 4680 battery cell format has been a topic of interest since Tesla introduced its own cell strategy at Battery Day in 2020. The company claimed that the new design could potentially reduce battery costs by over 50%. However, Tesla has faced bottlenecks in its efforts to bring it to volume production. During a conference call following the release of its Q1 2023 financial results, Tesla’s Senior VP of Engineering, Drew Baglino, gave an update on the production of the 4680 battery cell.

According to Baglino, Tesla is producing 4680 cells at its pilot plant in Fremont, but higher volume production is expected to take place at Gigafactory Texas. The Texas factory is referred to as the “cell factory” by Baglino and will have a 70% lower capex per gigawatt hour compared to typical cell factories when it is fully ramped up. Tesla is pursuing densification and investment reduction opportunities in future factory buildouts, such as in Nevada.

See also: Tesla possible shift to 800-volt architecture for Cybertruck and Semi

Baglino stated that Tesla is now in production with not only the first-generation tabless cell unveiled on Battery Day but also a second, more manufacturable version at its Texas facility. The company has a number of activities underway per the Battery Day roadmap on the cathode material side. Tesla aims to start commissioning portions of its Corpus Christi Lithium Refinery by the end of the year. The refinery uses the sulfate-free refining process with reduced process costs, no acid or caustic reagents, and lower embodied energy.

Baglino also gave an update on Tesla’s cathode factory at Gigafactory Texas, stating that Tesla has successfully demonstrated a lower process cost, zero waste water precursor process that they described on Battery Day. The company is on the detailed design phase for incorporating this technology into the front end of their Austin cathode facility. Tesla is 50% equipment and 75% utilities installed at its new cathode building in Austin, and the goal is to begin dry and wet commissioning this quarter and next quarter with a target to produce the first material before the end of the year.

The 4680 cell also enables Tesla’s new structural battery pack design. The Model Y in production at Gigafactory Texas is the first vehicle to feature this new chassis/battery pack design, and Tesla’s future vehicles, including the upcoming Cybertruck, are expected to have this design as well.

According to Baglino, Tesla saw significant improvements with pack manufacturing with the 4680 cell on the structural pack concept. The company believes that structural as a concept is good because it is simpler. Tesla will continue to structurally load the cells and use the pack as the floor of the vehicle while iterating the design to closer to B-level execution of this A-level architecture in future programs.

See also: Tesla plans to start production of 4680-format battery cells at the Texas Gigafactory this quarter

Baglino reported that Tesla made significant improvements in both cost and quality during the first quarter. On Texas production, Tesla increased 50% quarter-over-quarter, yields increased 12%, and peak rate increased by 20%. The company achieved a 25% reduction in COGS over the quarter and is on track to achieve steady-state cost targets over the next 12 months. Going forward for the rest of the year, the priority one is to yield in cost for the 4680 program as Tesla ramps up production ahead of Cybertruck next year.

Tesla’s detailed update on its 4680 battery program could indicate that the company is starting to overcome its bottlenecks. Tesla recently hired a new expert to help resolve its dry electrode issues in the 4680 program. As Tesla continues to work on this new battery technology, the industry will be watching