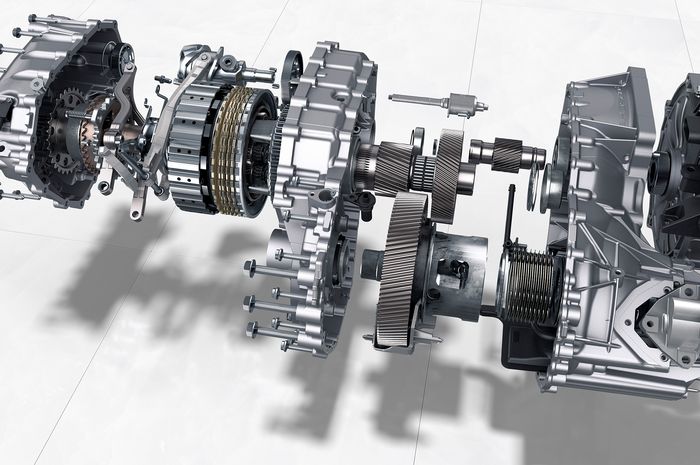

Electric cars generally use a single-speed transmission with a reduction gear mechanism.

The reduction gear of the electric car transmission is directly connected between the traction motor and the drive wheels.

The reduction gear consists of a small gear and a large gear to distribute electric power distribution.

Reduction gear is needed to reduce the rotation or rotation of the traction motor so that it is not the same as the rotation of the drive wheel. Simultaneously it also reduces the burden of transmitting electrical energy from the traction motor.

The traction motor will rotate very fast when generating electrical energy. Even in a small accelerator pedal, the rotating traction motor can reach tens of thousands of rpm.

If it is connected directly to the drive axle, the power distribution cannot be controlled. From the distribution of the reduction gear, the distribution of power to the drive wheels can be more linear and in accordance with the accelerator pedal control.

Likewise, if the traction motor is connected directly to the drive axle, the load on the electric motor will increase.

The seamless rotation of an electric motor must withstand the weight of components from wheel traction, axles, to wheel weights.

The small gear that is passed to the big gear makes the rotation of the electric motor still seamless but the distribution of power is distributed.