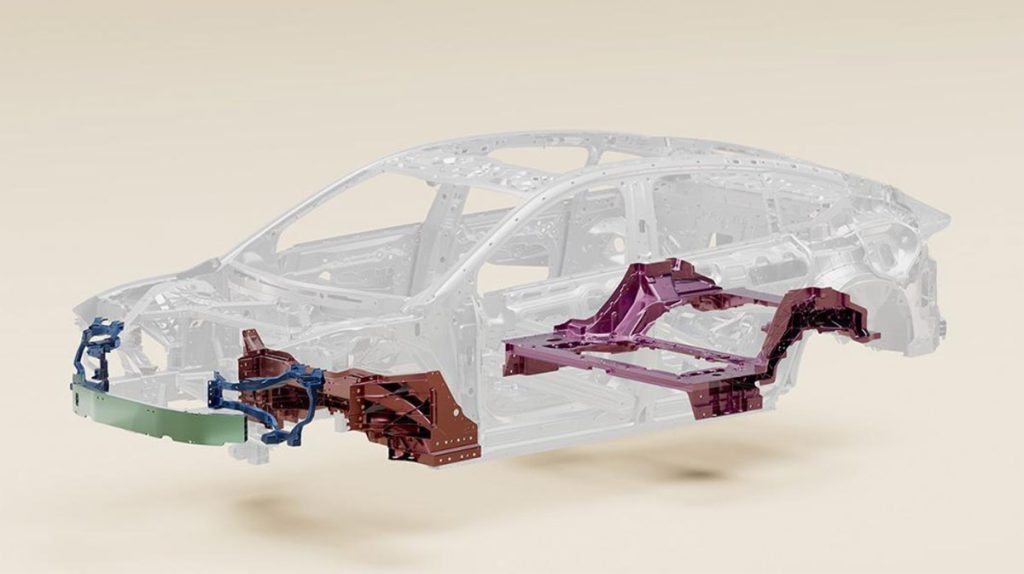

Nio has announced the development of a new self-hardening aluminum alloy designed for high-pressure die casting (HPDC), marking a significant milestone in the electric vehicle (EV) industry. This innovative material has already been used in the body-in-white of Nio’s ET9 and Onvo L60 models.

The new alloy, which is based on an aluminum-silicon alloy system, has been tailored through careful chemical tuning and multiple trial runs in Nio’s die-casting facilities. According to Liu Huachu, principal researcher at Nio’s Materials Research and Applications (MRA) team, the material is proven to be suitable for making large, structural castings such as rear floors and battery casings.

See also: Spy Photo Reveals Interior of Nio’s Firefly Sub-Brand Model Ahead of April Launch

Gary Hughes, MRA team leader, explained, “After balancing cost and performance, Nio released the new alloy to the vehicle program,” noting the collaboration between Nio’s design, manufacturing, and industrialization teams, which led to the successful validation of the alloy before mass production.

The development of the alloy breaks the monopoly of the C611 aluminum alloy in China’s large die-casting market, marking the first self-hardening aluminum alloy for structural large castings developed by a Chinese automotive brand. The alloy technology is now open to the entire automotive industry, with Nio stating that it will help drive the adoption of high-pressure die casting, enhancing both performance and cost-effectiveness.

See also: Nio to Launch New Models and Facelifts Across All Brands in 2025

The new material has been validated with the support of Nio’s partners, including alloy maker CSMET and high-pressure casting vendors Wencan and Huihan. Nio is positioning this innovation as a significant leap forward in the economic, environmental, and intellectual property benefits for China’s automotive industry.