Researchers at RWTH Aachen University’s Chair of Production Engineering of E-Mobility Components (PEM) have reportedly developed a new laser process that significantly reduces the drying time for battery electrodes, potentially revolutionizing the production of lithium-ion batteries.

The high cost of lithium-ion batteries, which account for 31% of the total costs of an electric car according to PEM, has been a major barrier to widespread adoption of electric vehicles. Current production processes, in addition to raw material procurement, contribute significantly to these costs.

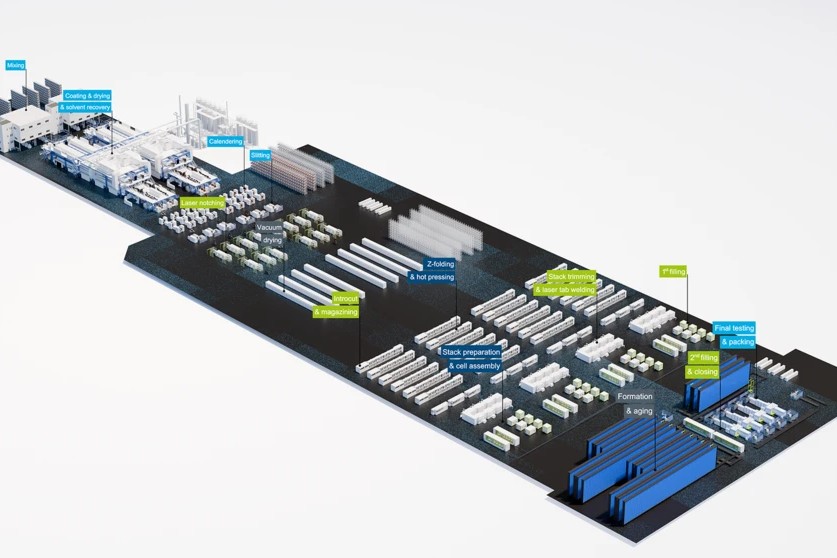

One of the most energy-intensive steps in battery production is the drying of electrode paste, which is applied as a slurry and then dried in large ovens to remove the liquid components. The new laser-based process, developed in collaboration with spin-off engineering service provider PEM Motion and laser specialist Trumpf, aims to reduce this drying time while maintaining or improving quality.

According to the researchers, the new technology allows for “a significant reduction in drying time with at least the same quality compared to the current state of the art.” VCSEL-based laser heating systems are key to this advancement, reportedly reducing operating costs and CO2 consumption by up to 40%. Furthermore, equipment costs could be slashed by up to 50% while maintaining electrode and cell quality.

The modular design of the VCSEL laser heating systems enables precise drying, with separate zones for control of individual illumination areas. The compactness and short working distance of the modules facilitate easy integration into existing systems.

Professor Achim Kampker, Head of PEM, expressed his optimism about the new process, stating, “This step enables a much more energy-efficient, high-quality, and cost-effective production of batteries.” Ralph Gudde, Vice President of Marketing and Sales at Trumpf Photonic Components, highlighted the advantages of laser drying, including improved energy efficiency, reduced floor space, and better process control.

The results of the experimental study conducted by RWTH Aachen University, PEM Motion, and Trumpf are detailed in a white paper in English, showcasing the potential of the new technology.

In April, PEM announced another breakthrough in battery drying technology, developing a method for drying LFP cathodes and graphite anodes using a laser process as part of the IDEEL research project, in collaboration with the Fraunhofer Institute for Laser Technology (ILT).