Researchers at the University of Science and Technology of China (USTC) in Hefei have unveiled a groundbreaking lithium-metal battery design that could revolutionize energy storage capabilities for electric vehicles and beyond.

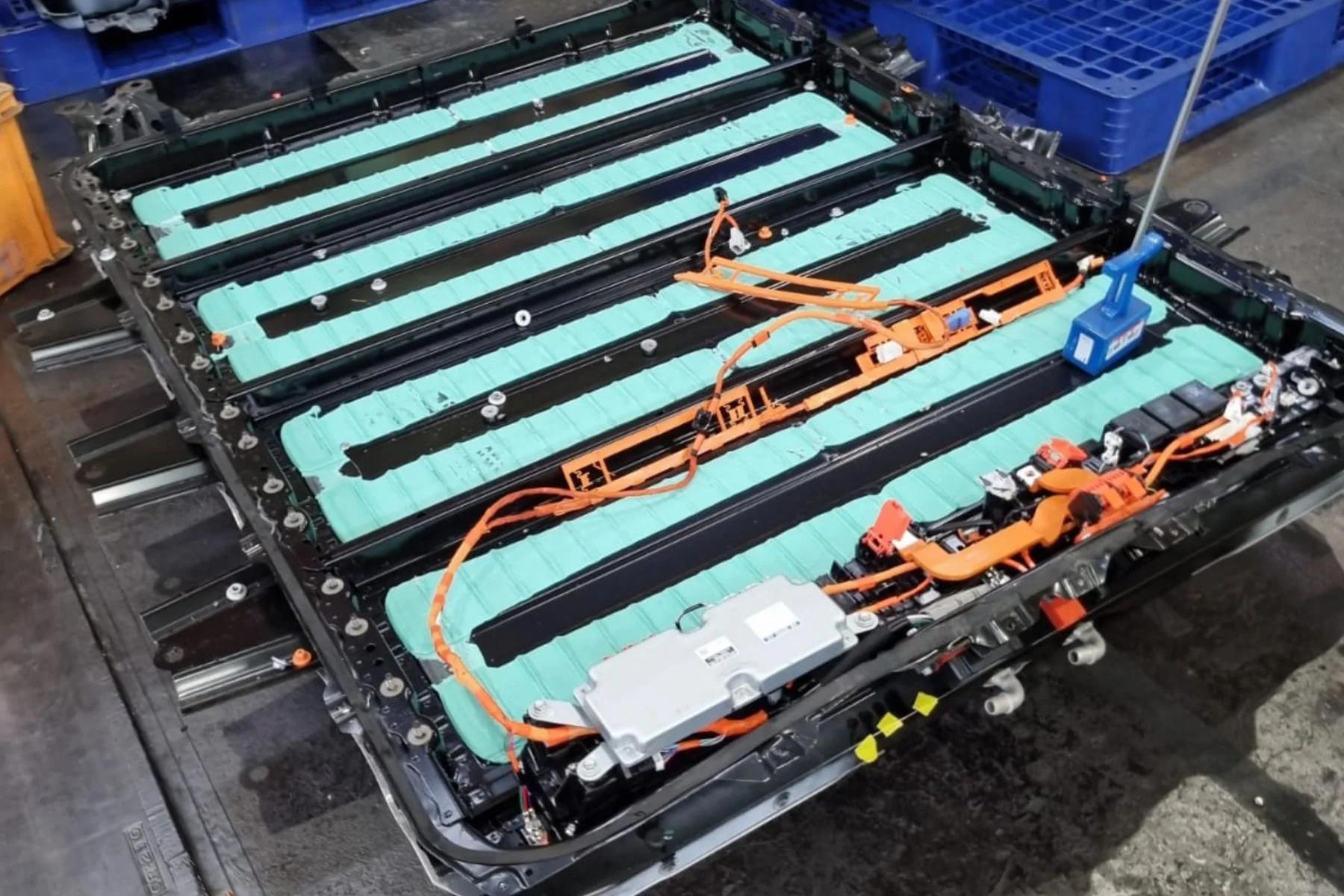

Traditionally, electric vehicle batteries offer energy densities ranging from 200 to 250 watt-hours per kilogram (Wh/kg), limiting their efficiency and overall weight savings. In contrast, home energy storage systems achieve approximately half of this density.

The new battery prototype, boasting an impressive energy density of 505.9 Wh/kg, marks a significant leap forward in battery technology. This advancement could potentially reduce vehicle weight by up to 150 kilograms (330 pounds), translating to enhanced fuel efficiency and improved driving performance.

“In previous experiments, lithium-metal batteries fell short, struggling to endure more than 50 charging cycles,” stated researchers. “Our novel approach focuses on optimizing electrolyte concentration, achieving a robust structure capable of surviving over 130 cycles with minimal capacity loss at 500 Wh/kg.”

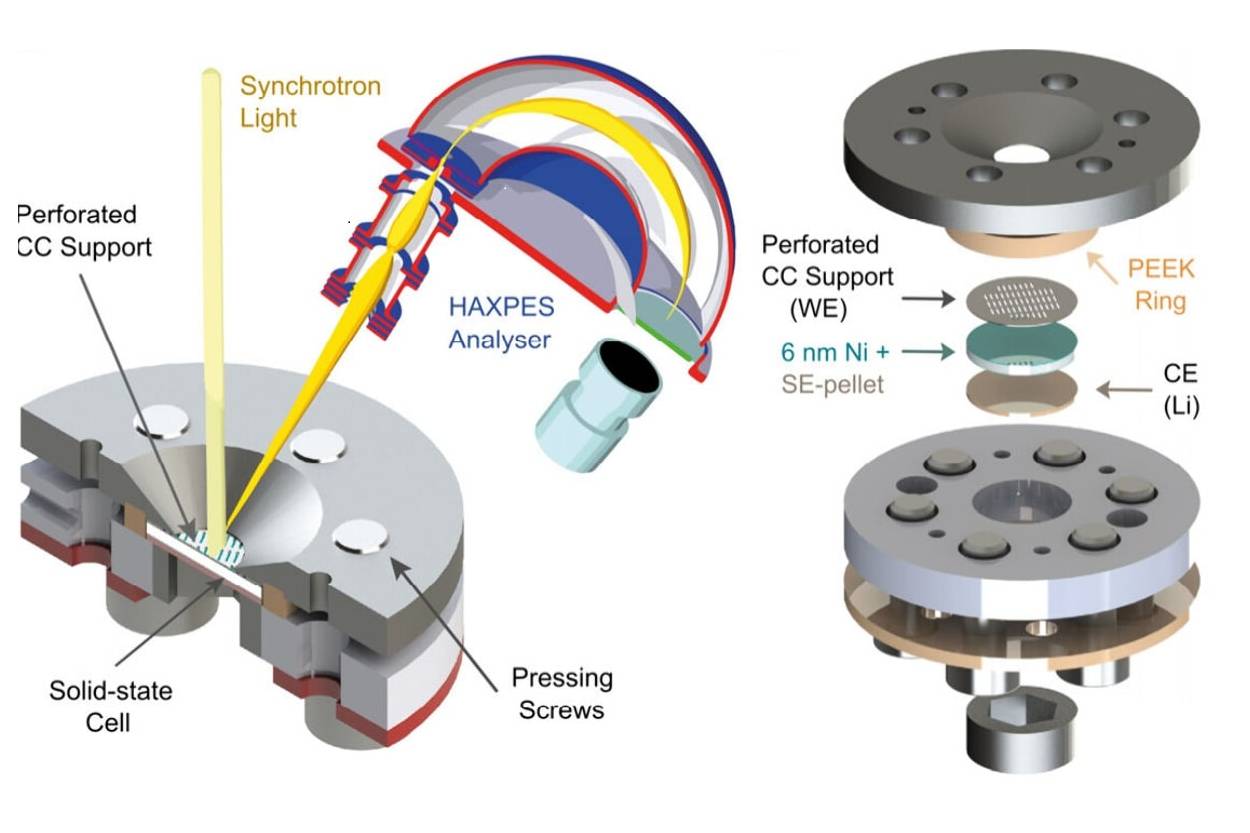

Key to this innovation is a redesigned architecture featuring densely packed lithium ions that facilitate electron transport to the anode more efficiently. This structural refinement not only enhances stability but also extends battery lifespan, offering over 300 charging cycles even at 400 Wh/kg — significantly surpassing current commercial standards.

Looking ahead, optimizing this pioneering battery design remains a top priority. The research team aims to further enhance durability to meet the demands of prolonged use. For instance, achieving an estimated range of 500 kilometers (300 miles) before a notable decline in capacity after approximately 150,000 kilometers (90,000 miles) of travel is a promising target.

As the automotive industry shifts towards sustainable mobility solutions, the USTC’s breakthrough could pave the way for lighter, more efficient electric vehicles and broader applications in renewable energy storage.