FREYR Battery and Nidec Corporation have announced that they have established a downstream joint venture, now called Nidec Energy AS (“Nidec Energy”).

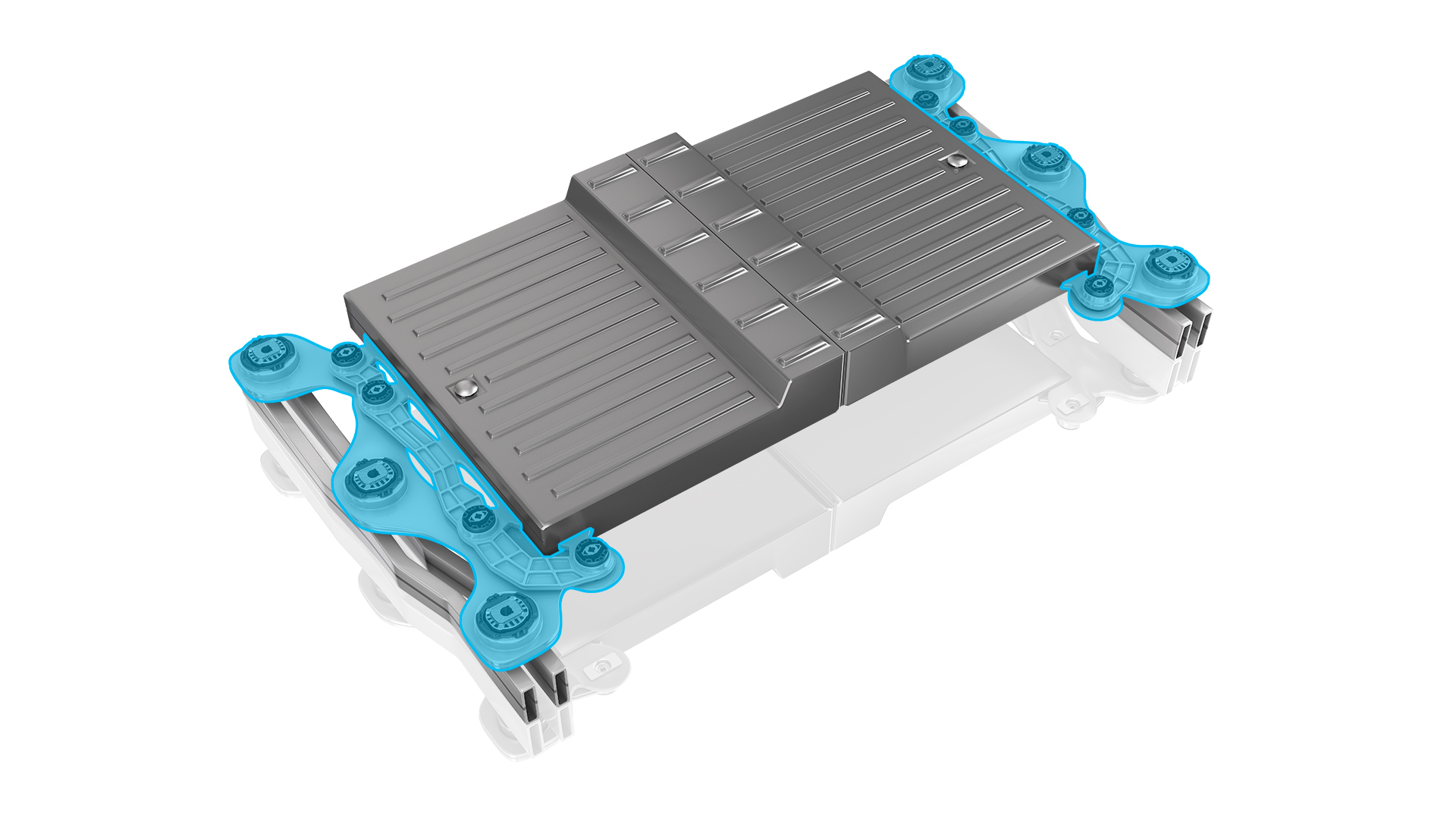

The newly established Nidec Energy aims to develop and supply highly competitive, integrated battery energy storage solutions (“BESS”) and products with low environmental impact. Mass production is expected to commence in 2025, with the ambition to manufacture more than 8 GWh per year of battery modules and packs from 2027, and 12 GWh per year by 2030.

“The official incorporation of the joint venture with Nidec is a significant milestone in our journey to bring speed, scale, and sustainability to battery storage solutions globally,” remarked Tom Einar Jensen, FREYR’s Co-Founder and Chief Executive Officer. “This partnership will enable us to accelerate the development of our highly competitive, low carbon modules and battery pack solutions for industrial and utility grade applications,” Jensen added.

Nidec Energy’s module production is expected to be integrated into FREYR’s Giga Arctic development, with volumes of integrated ESS solutions aligning with the company’s targeted ramp up of cell production in 2024. In addition, the joint venture is expected to invest more than $127 million by 2030, and eventually employ more than 300 people, the majority of whom will be based in Mo i Rana, Norway.

“We are thrilled by the progress we have made with FREYR. This joint venture will support the development of our fast-growing ESS business and aligns with our firm commitment to develop technologies that contribute to reducing global carbon emissions,” said Laurent Demortier, President of Nidec’s Energy & Infrastructure Division. “For us, FREYR is a natural partner with clean energy and sustainability ambitions. They also bring expertise and resources related to battery cell design and manufacturing, which includes the market-leading 24M SemiSolidTM lithium-ion battery cell technology.”

As one of the prerequisites to establishing the joint venture, a package of 24M Technologies (“24M”) sample cells was sent to a leading independent third-party laboratory for testing on behalf of Nidec. The purpose of the testing was to measure the capacity, charge, and discharge profiles of the cells, in addition to technical performance, to confirm that the operation of the cells was consistent with the specifications and data provided by FREYR.

Freyr battery opens new business unit and technology resources campus in Japan