In a collaborative effort with partners from the automotive industry, Fraunhofer Institute for Reliability and Microintegration (IZM) is spearheading the Dauerpower project, aimed at revolutionizing electric vehicle (EV) technology. The project focuses on developing an electrical inverter with enhanced cooling capabilities, promising improved continuous load capacity and cost efficiency.

The key innovation lies in the inverter’s ability to operate at lower temperatures, achieved through optimized cooling management, which significantly reduces power loss. This breakthrough not only extends full-load utilization but also minimizes the required semiconductor area, contributing to lower costs associated with electric mobility transition.

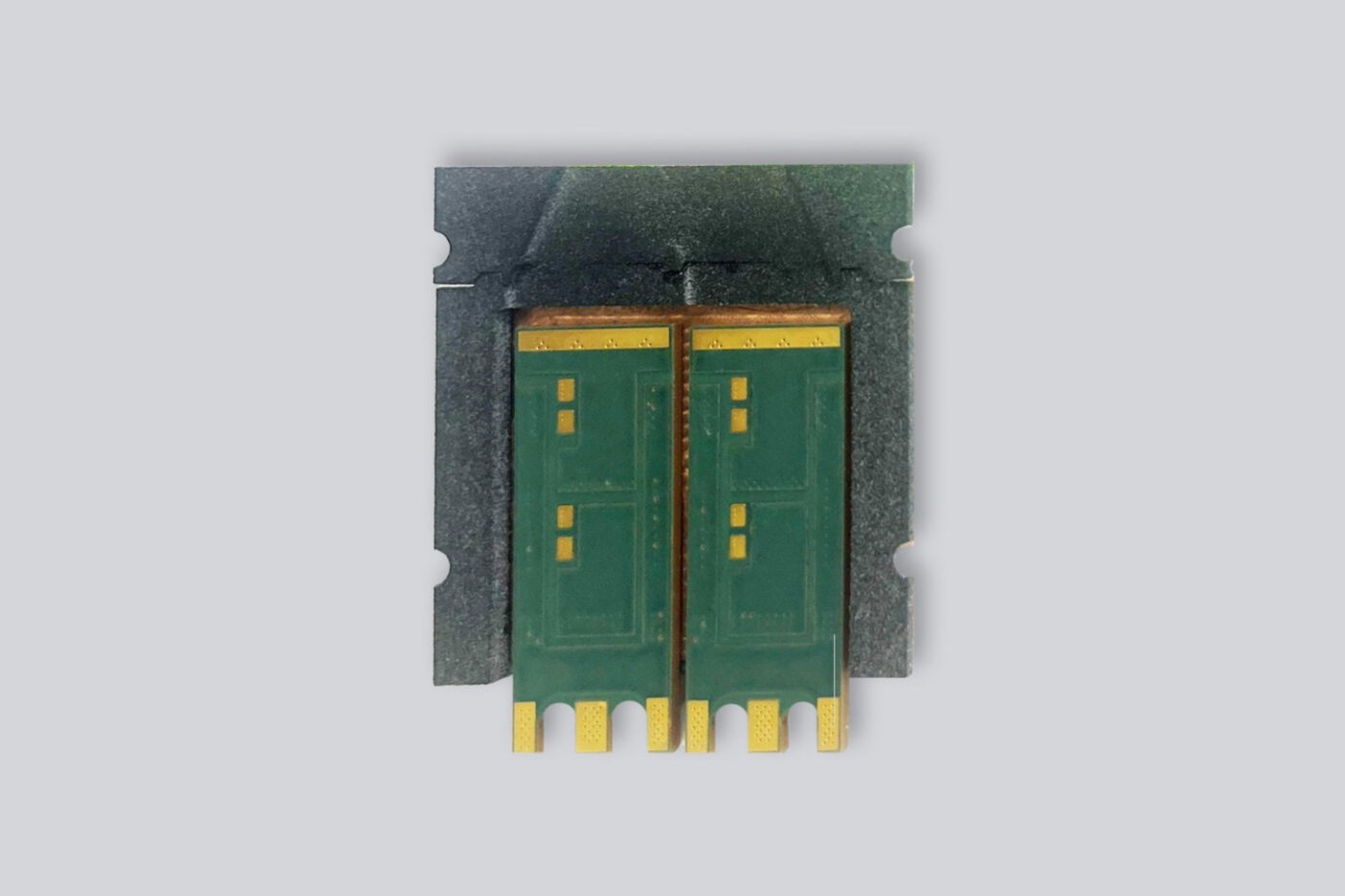

Dr. Michael Bruemmer, Head of Department at Fraunhofer IZM, highlighted the significance of thermal behavior in electric drivetrain components such as the electric motor, battery, and power electronics, including the inverter. Silicon carbide semiconductors, known for their superior efficiency and compactness, are already utilized in inverters in current series-produced electric cars. Fraunhofer IZM takes this a step further by employing a novel “innovative prepackaging process” where two silicon carbide transistors are directly applied to a ceramic substrate. This approach enhances mechanical stress tolerance and deformation behavior under heat, while optimizing space utilization.

Moreover, the cooling system has been reimagined to further enhance efficiency. Fraunhofer IZM integrates semiconductors and passive components directly into the cooling system, leveraging innovations such as 3D-printed copper cooling elements. This advancement allows for superior thermal conductivity of copper, previously limited to aluminum heat sinks, and offers design flexibility for cooling channels, optimizing installation space usage.

The prototype, currently in the construction phase following extensive simulation, boasts greater modularity, with elements integrated into replaceable and repairable sub-modules, saving resources. Partners Bosch and Porsche are actively involved in the project, with Porsche conducting rigorous testing to pave the way for series production. The inverter is designed to deliver a continuous output of 720 kW and a rated current of 900 amps, catering to high-performance requirements.