The European Commission plans to amend the EU Battery Regulation in 2027, shifting the basis for calculating the CO2 footprint of electric vehicle batteries from the actual electricity used to the national electricity mix. This proposal has sparked opposition from Germany’s automotive industry.

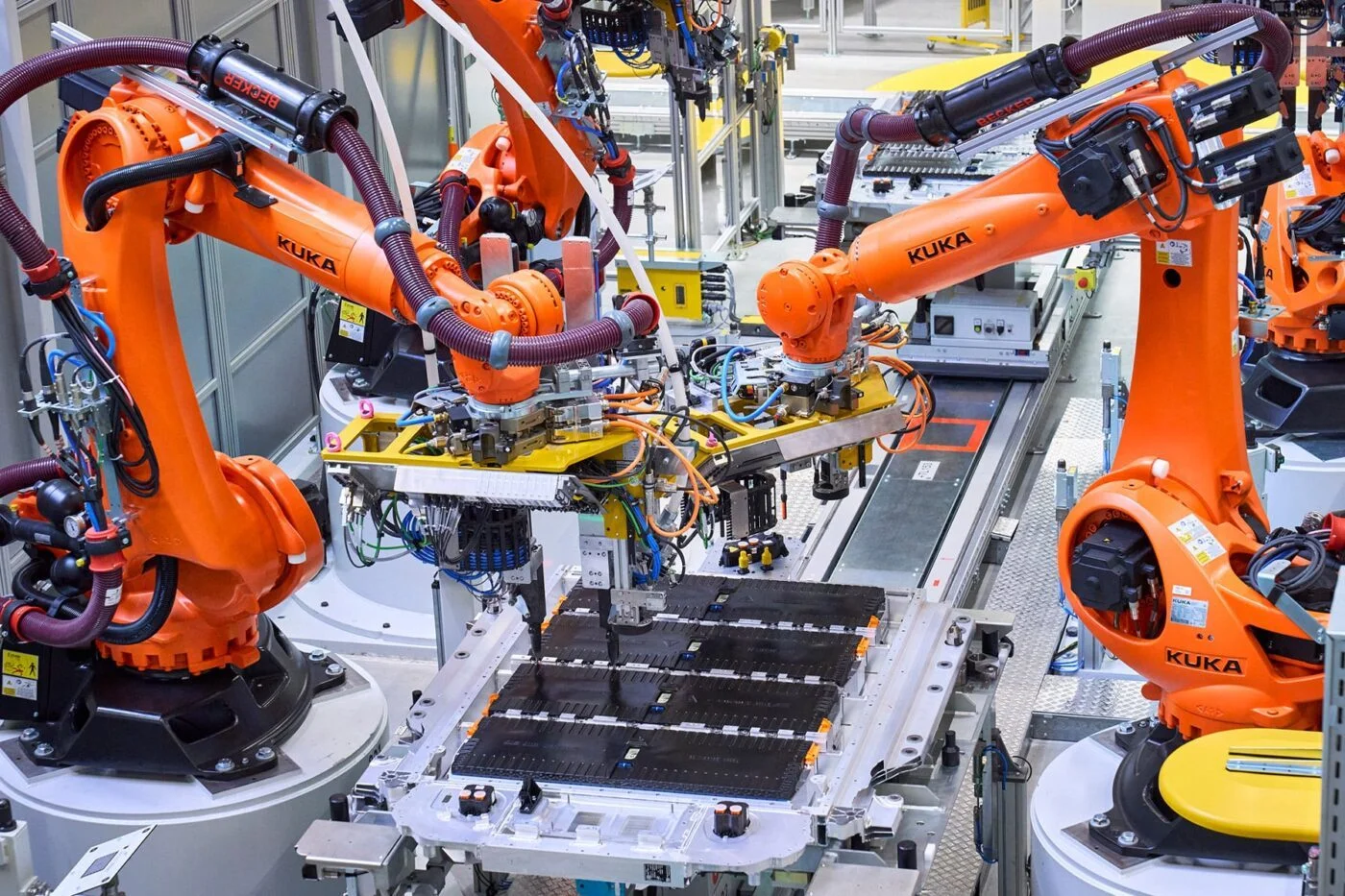

The EU’s Battery Regulation, aimed at promoting the circular economy, came into force in August 2023, with most provisions effective since February 2024. The Commission, which initiated the regulation in 2020, now seeks to adjust the calculation method for the CO2 footprint of car batteries. From 2027, the CO2 footprint will be based on the national electricity mix rather than the specific electricity used during production.

Germany’s automotive sector is concerned about this change, arguing that the national electricity mix, which includes a significant proportion of coal and gas, would unfairly penalize German-produced batteries compared to those from countries like France, which rely more on nuclear power and renewable energy. In 2023, approximately 40% of Germany’s electricity came from fossil fuels, according to Manager Magazin.

Manufacturers prefer using Power Purchase Agreements (PPAs) with electricity providers to source greener energy and argue that the new regulation would inaccurately portray their batteries as less environmentally friendly. The German Association of the Automotive Industry (VDA) expressed concerns, stating, “The automotive industry itself has little influence on the overall national/regional energy mix. This draft is at odds with previous approaches and would bring significant disadvantages for existing locations in Germany.”

The EU Battery Regulation aims to ensure supply security and stimulate the circular economy. Key aspects include mandatory declarations and labelling related to battery components and recycled material content, an electronic “battery passport,” and a QR code. These labelling requirements will start in 2026, with the QR code following in 2027.

The regulation also sets targets for recycling materials from waste batteries, requiring 50% of lithium to be recovered by 2027 and 80% by 2031. For cobalt, copper, lead, and nickel, the targets are 90% by 2027 and 95% by 2031. Additionally, new batteries must contain specific percentages of these recovered materials, with gradual increases set for 2031 and 2036.

To address environmental and social due diligence, market participants must verify the origin of raw materials and labor conditions in their supply chains. However, small and medium-sized companies will have some exceptions from these requirements.