In a significant advancement toward addressing the mounting challenge of lithium iron phosphate (LFP) battery waste, a team of researchers from China has unveiled a pioneering self-powered recycling system. This novel system, combining an electrochemical Li-ion battery (LIB) recycling reactor and a triboelectric nanogenerator (TENG), holds the potential to revolutionize the sustainable disposal of spent LFP batteries.

Published in the esteemed RSC journal Energy & Environmental Science, the research article outlines the ingenious method developed by the Chinese team. The central components of their innovation are the electrochemical LIB recycling reactor and the TENG, working in tandem to effectively recycle used LFP batteries.

See also: 6 Types of Electric Vehicle Batteries You Need to Know

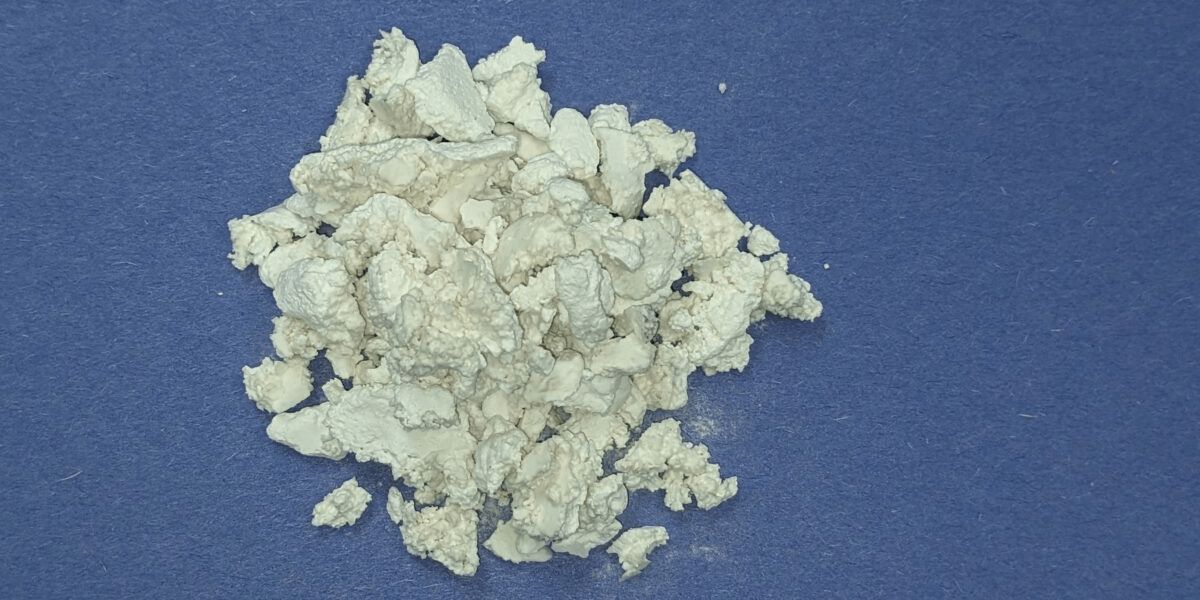

The core principle behind the electrochemical LIB recycling reactor hinges on the utilization of the Cl−/ClO− pair, which is generated through electrochemical processes in a sodium chloride (NaCl) solution. This redox mediator plays a pivotal role in disintegrating LFP batteries into two main constituents: FePO4 and Li+. This process, known as a redox targeting reaction, obviates the need for additional chemicals, thus streamlining the recycling procedure.

Complementing the electrochemical reactor is the triboelectric nanogenerator (TENG), ingeniously crafted from discarded elements of LIBs such as casings, aluminum-plastic films, and current collectors. The TENG, designed to harness wind energy, produces an impressive power output of 0.21 W. This energy not only powers the electrochemical recycling system but also serves in recharging batteries, establishing a self-sustaining loop.

The ingenuity of this recycling system lies not only in its efficiency but also in its eco-conscious design. By repurposing components from used batteries, the TENG significantly curbs the creation of secondary pollutants, addressing a persistent concern associated with battery recycling. This approach aligns well with the global push for greener practices.

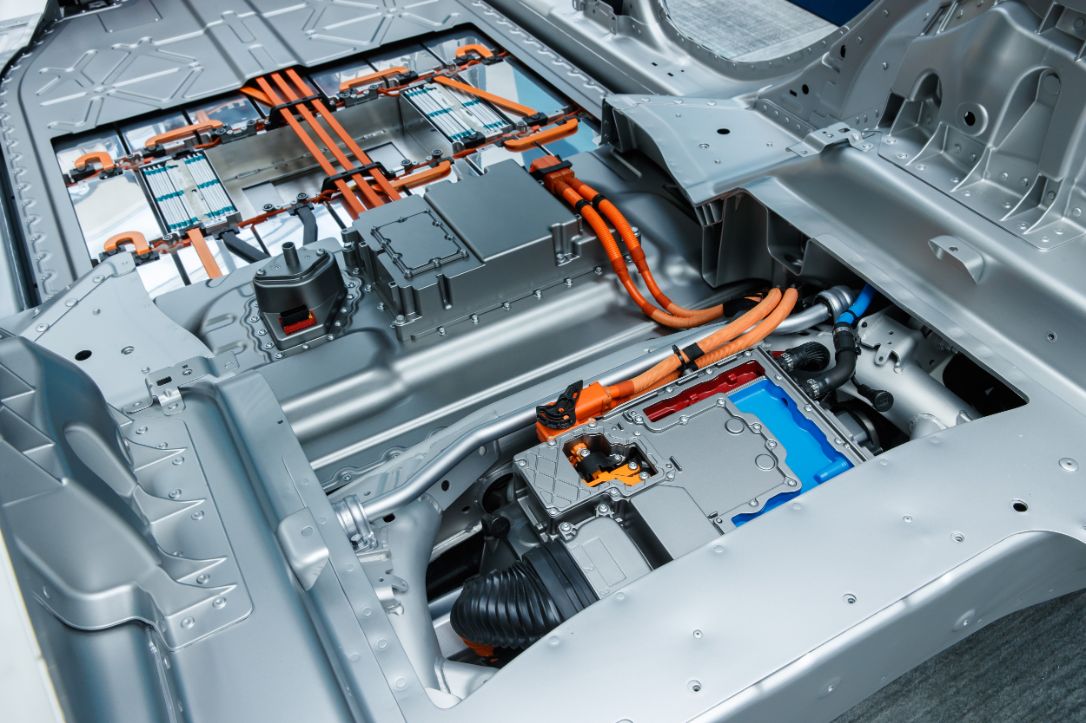

LFP batteries occupy a substantial 32% share of the global lithium-ion battery (LIB) market. Despite their prominence, the recycling of these batteries has been marred by the limitations of existing methods. Conventional recycling technologies, predominantly based on electrochemical or chemical leaching processes, have long grappled with issues like complex procedures, excessive chemical and electricity consumption, and the release of secondary pollutants.

The researchers assert that their proposed recycling system offers a multifaceted solution to these challenges. By achieving high purity levels of 99.70% for Li2CO3 and 99.75% for FePO4, the system ensures that the recycled materials are of superior quality. The self-powered aspect of the system adds to its allure, presenting a streamlined approach that simplifies the recycling process while minimizing external energy requirements.

See also: Republic Services Unveils First Fully Integrated Electric Recycling and Waste Collection Truck

In a world that is becoming increasingly conscious of environmental sustainability, this innovation could mark a pivotal step forward in enhancing the viability of LIB technologies. As the demand for batteries continues to surge across industries, solutions like these could contribute significantly to a cleaner, more efficient future.

As this research ushers in a new era of battery recycling, the implications could extend beyond LFP batteries, influencing the broader landscape of waste management and sustainable technology development. The combination of inventive science and environmental stewardship showcased by this Chinese research team underscores the potential for groundbreaking change on a global scale.