Atlas Materials, a U.S.-based company pioneering an innovative technology for processing low-grade nickel ore suitable for electric vehicle (EV) batteries, has successfully raised $27 million in funding. The funding injection marks a significant milestone as the firm prepares to construct a pilot plant in North America, according to an announcement made by the startup.

Atlas has devised a groundbreaking method to transform a specific type of nickel ore traditionally used in stainless steel production into a suitable form for EV batteries. Importantly, this process generates minimal emissions and produces no waste.

CEO Jeremy Ley outlined the company’s ambitious plans, revealing that Atlas intends to commence production at a pilot plant by 2027, choosing from three potential locations in Canada or the United States. The facility is expected to have an annual nickel output of 1,800 metric tons.

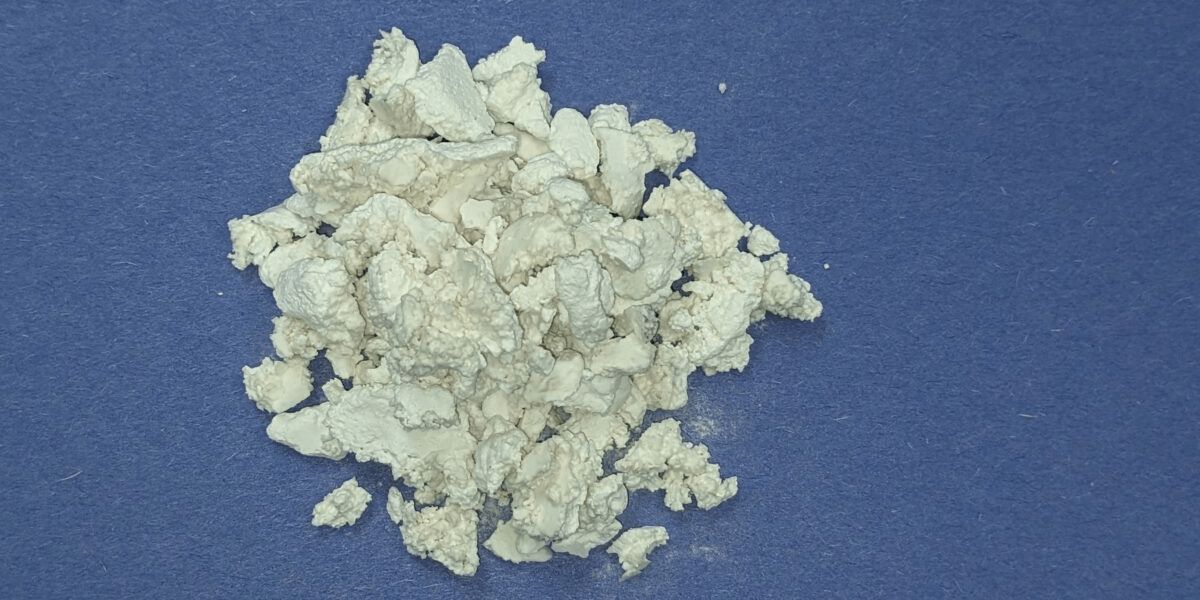

Atlas specializes in processing saprolite nickel ores, a resource that constitutes approximately one-third of the world’s nickel reserves. Through their innovative approach, the company converts these ores into mixed hydroxide precipitate (MHP) for use in batteries.

“This would be the first production of MHP in North America,” noted Ley.

Traditionally, saprolite ores are typically transformed into ferronickel for stainless steel production. Atlas’ breakthrough processing technology employs hydrochloric acid and caustic soda to leach the ore, eliminating the need for high-pressure or high-temperature conditions and minimizing waste.

Notably, the ore-to-MHP process yields two valuable byproducts: magnesium hydroxide and a material suitable as a substitute for portland cement in construction, both of which can be commercialized.

Ley emphasized the sustainability aspect of their technology, highlighting its near-zero carbon dioxide emissions. Unlike some alternative processes, such as high-pressure acid leaching (HPAL) used in Indonesia, which generates toxic waste, Atlas’ method stands out for its eco-friendliness.

Atlas Materials’ Series A Funding round secured support from investors including the Grantham Environmental Trust and Voyager Ventures, bringing the company’s total financing to $33 million. While this funding will contribute to engineering and design work for the pilot plant, further financial backing will be necessary for the plant’s actual construction, according to Ley.