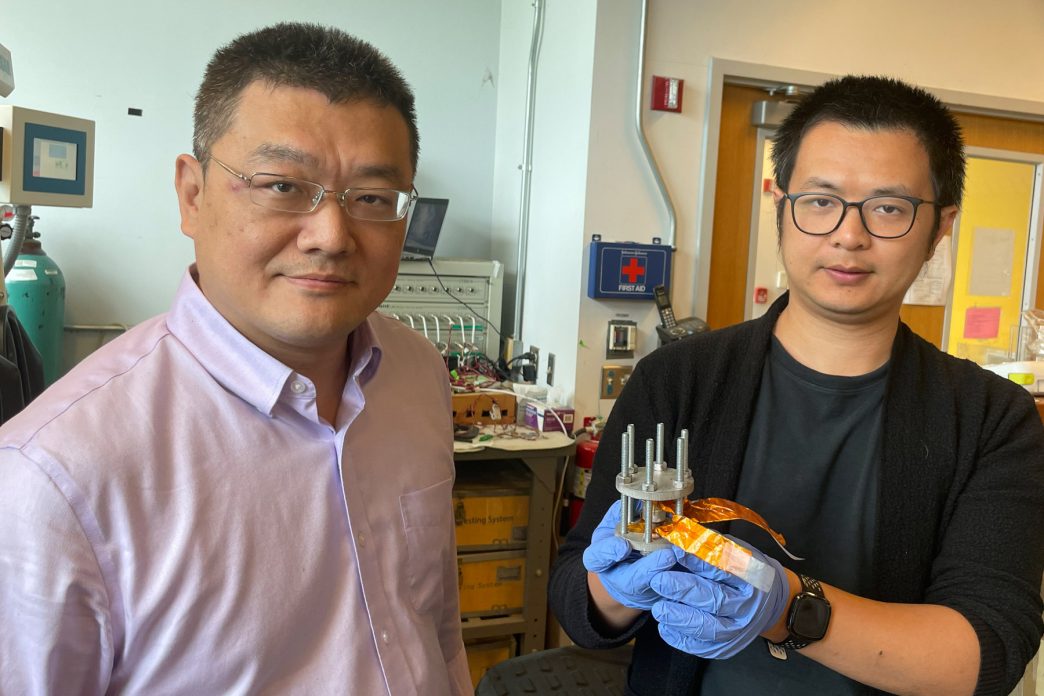

Researchers at the Georgia Institute of Technology have unveiled a low-cost cathode material for lithium-ion batteries that could significantly reduce costs for electric vehicles (EVs) and energy storage systems. The material, iron chloride (FeCl3), is said to cost only one to two percent of conventional cathode materials while delivering comparable efficiency.

“For a long time, people have been looking for a lower-cost, more sustainable alternative to existing cathode materials. I think we’ve got one,” said Hailong Chen, associate professor at the George W. Woodruff School of Mechanical Engineering and the School of Materials Science and Engineering. “Our cathode can be a game-changer.”

The new cathode, combined with a solid-state battery design featuring a chloride-based solid electrolyte and a lithium metal anode, could lower the overall cost of batteries by 30-40% compared to current lithium-ion systems. Early tests suggest that FeCl3 outperforms traditional cathodes like nickel oxide and lithium iron phosphate (LiFePO4), offering a higher operating voltage.

Despite promising results, the research remains at the laboratory scale. Scaling the technology to larger battery formats for EVs and grid-scale energy storage presents challenges. “We want to make the materials as perfect as possible in the lab and understand the underlying functioning mechanisms,” Chen said. “But we are open to opportunities to scale up the technology and push it toward commercial applications.”

Chen’s team has been working on solid-state batteries since 2019, initially encountering compatibility issues between oxide-based cathodes and chloride electrolytes. The breakthrough came when FeCl3 was identified as a suitable alternative. “This could not only make EVs much cheaper than internal combustion cars, but it provides a new and promising form of large-scale energy storage, enhancing the resilience of the electrical grid,” Chen explained.

While the researchers estimate the technology could reach commercial viability within five years, further work is needed to address the challenges of scaling up production. The development marks a step toward more affordable and sustainable energy solutions in the evolving battery market.

Source: gatech.edu