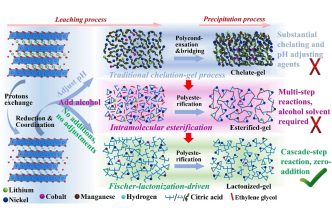

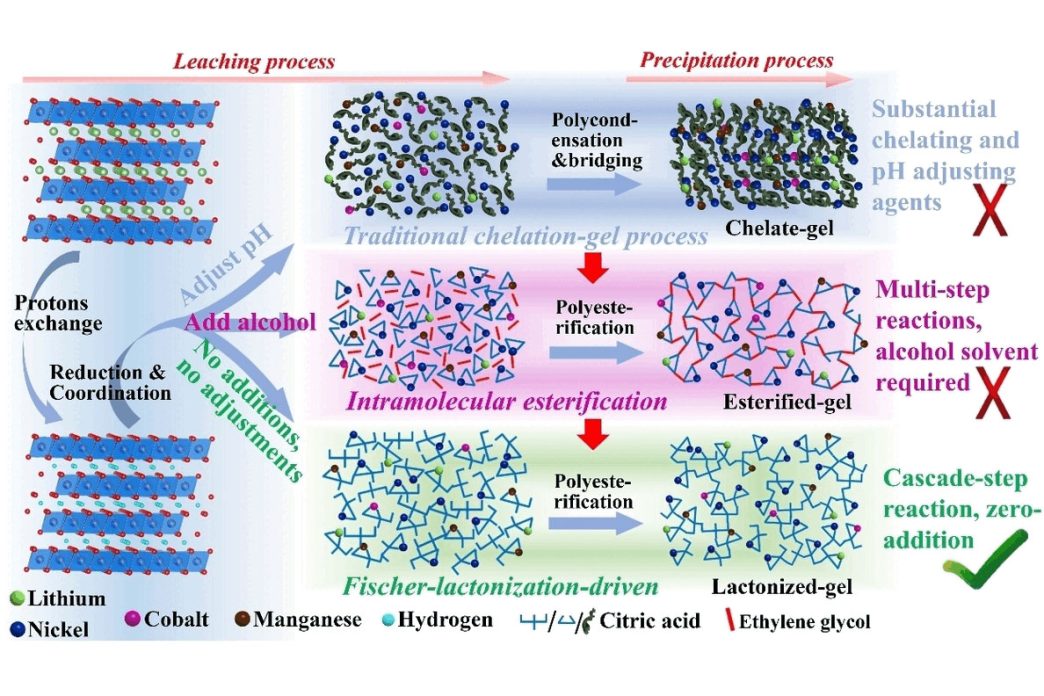

Researchers from leading Chinese universities have pioneered a sustainable method to recycle nickel-cobalt-manganese (NCM) batteries, using citric acid to extract and separate key metals with high efficiency. The innovative process, detailed in the journal Angewandte Chemie, promises to address the environmental and cost challenges associated with traditional recycling methods.

The research, a collaboration between the China University of Mining and Technology (Beijing), Fuzhou University, Beijing University of Chemical Technology, and Tsinghua University (Shenzhen), demonstrated that over 99% of lithium, nickel, cobalt, and manganese could be reclaimed using a minimal amount of citric acid. Unlike conventional methods, which often rely on excessive chelating agents and complex procedures, this process is energy-efficient and significantly reduces CO2 emissions.

“Our experiment produced a new NCM lamellar framework, which can be directly used as a high-quality electrode material,” said Dr. Ruiping Liu, the lead researcher. She explained that the novel approach avoids the high emissions and limited material quality typical of current recycling processes.

NCM batteries, widely used in smartphones and electric vehicles, have a limited lifespan, making efficient recycling critical for resource conservation and environmental protection. The researchers emphasized that their method’s simplicity and lower environmental impact could make it a viable alternative for large-scale battery recycling in the future.