The European Union has launched the BATTwin project with the goal of establishing efficient and sustainable production of lithium-ion batteries in Europe, reducing dependence on other nations. Led by the Polytechnic University of Milan (Italy), the project aims to develop digital twins of battery factories by May 2027 to reduce waste, energy requirements, and emissions from cell production, ultimately creating a European “zero-defect gigafactory.”

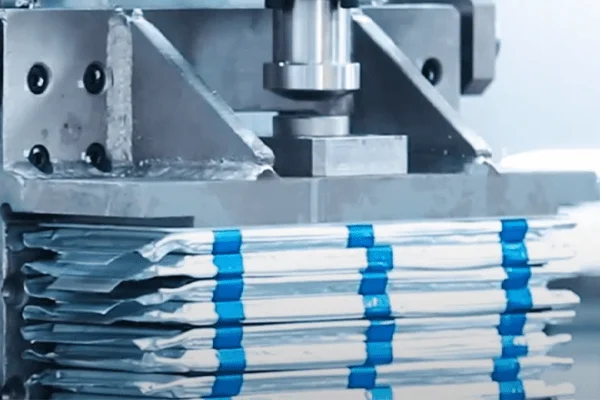

One crucial aspect being investigated in Oldenburg is how to avoid producing faulty battery cells. Andreas Rauh, leading the team from the ‘Distributed Control in Networked Systems’ department, is focusing on reducing the current reject rate of around ten percent. The team is developing models of cell production stages based on physical processes, coupled with data-driven processes, to improve the production process and optimize control variables not only during the design phase but also during operation.

Rauh’s team is also establishing a laboratory infrastructure to experimentally test the charging and discharging processes of individual battery cells on their test bench. This setup will allow them to test their models, enabling conclusions about battery cell condition and ageing based on measurements available during operation.

Funded by the EU’s Horizon Europe program with around 6.4 million euros, BATTwin includes six universities, research institutions, and ten industry partners from across Europe, including plant manufacturer Comau and battery manufacturer Verkor. Approximately 630,000 euros of the funding will go to the University of Oldenburg.