Kia Motors has announced the construction of a dedicated plant for the production of battery-electric purpose-built vehicles (PBV) at its Hwaseong plant in South Korea. The groundbreaking ceremony was held on Monday, April 12, and was attended by more than 200 people, including government officials, executives from Hyundai Motor Group and Kia Motors, and employees from the automotive parts industry.

During the ceremony, Kia Motors’ Global President and CEO, Ho Sung Song, reiterated the company’s commitment to investing KRW 24 trillion (approximately USD 20.8 billion) in the domestic electric vehicle industry by 2030. Song said that this investment would focus on enhancing the competitiveness of the entire electric vehicle ecosystem, including research and development, production, and infrastructure. He added that the goal was to make South Korea one of the top three players in the global EV market and to lead the way in driving change and innovation in the new global automotive industry.

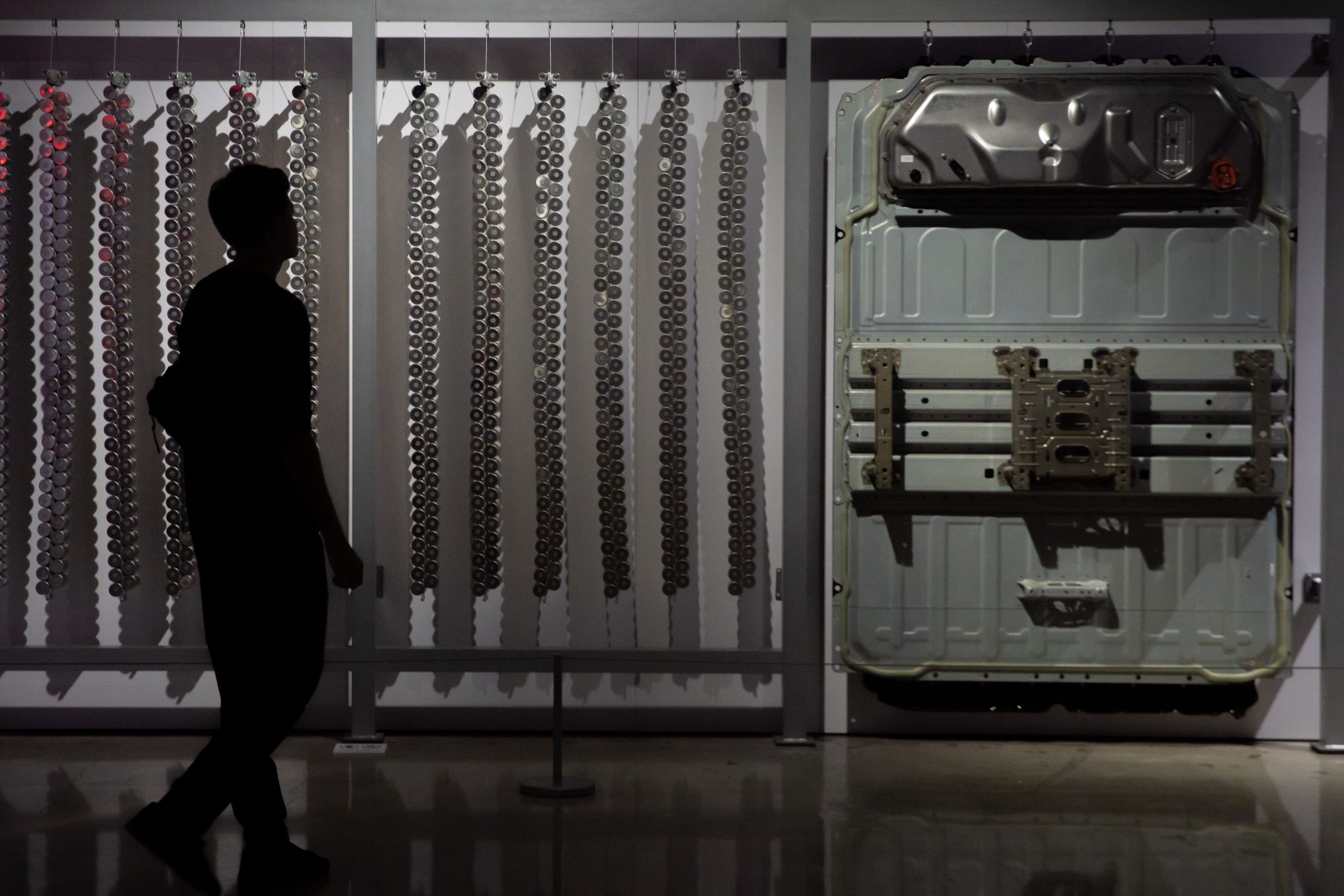

The new PBV plant will be built as an eco-friendly facility that applies future innovative manufacturing technologies while minimizing carbon emissions. With an annual production capacity of 150,000 units, Kia plans to invest around KRW 1 trillion (approximately USD 758 million) to secure 99,000 acres of land, with mass-production set to begin in the second half of 2025. The plant will use a cutting-edge smart factory system that unifies the new cell method with the original mass-production conveyor system, allowing flexible production with more customization of various product types.

One of the innovative manufacturing processes to be implemented at the new PBV plant is known as the ‘cellular (or cell) method,’ which allows vehicle production based on diverse customer demands. The cell method is a process layout strategy that groups together machines or workstations that are used to produce similar products or parts. This aims to create a more efficient and flexible manufacturing process by reducing the distance that materials and products need to travel during production.

The PBV plant’s cutting-edge manufacturing system also incorporates several innovative technologies, such as automation of facilities using machine learning and artificial intelligence (AI), automation of painting quality inspection under the vehicle, automation of installation of parts such as glass, vehicle name, and company logo, and real-time automatic measurement quality data analysis to autonomously correct and install the vehicle body in real time.

Kia’s new facility will be a ‘human-friendly’ plant by pushing automation in heavy-duty work and tasks that require looking up at the ceiling, while enhancing the feeling of ‘openness’ and also reducing noise levels. The company will also reduce carbon emissions by about 20 percent compared to existing factories by utilizing natural light and streamlining the manufacturing process, making the PBV plant a low-carbon factory.

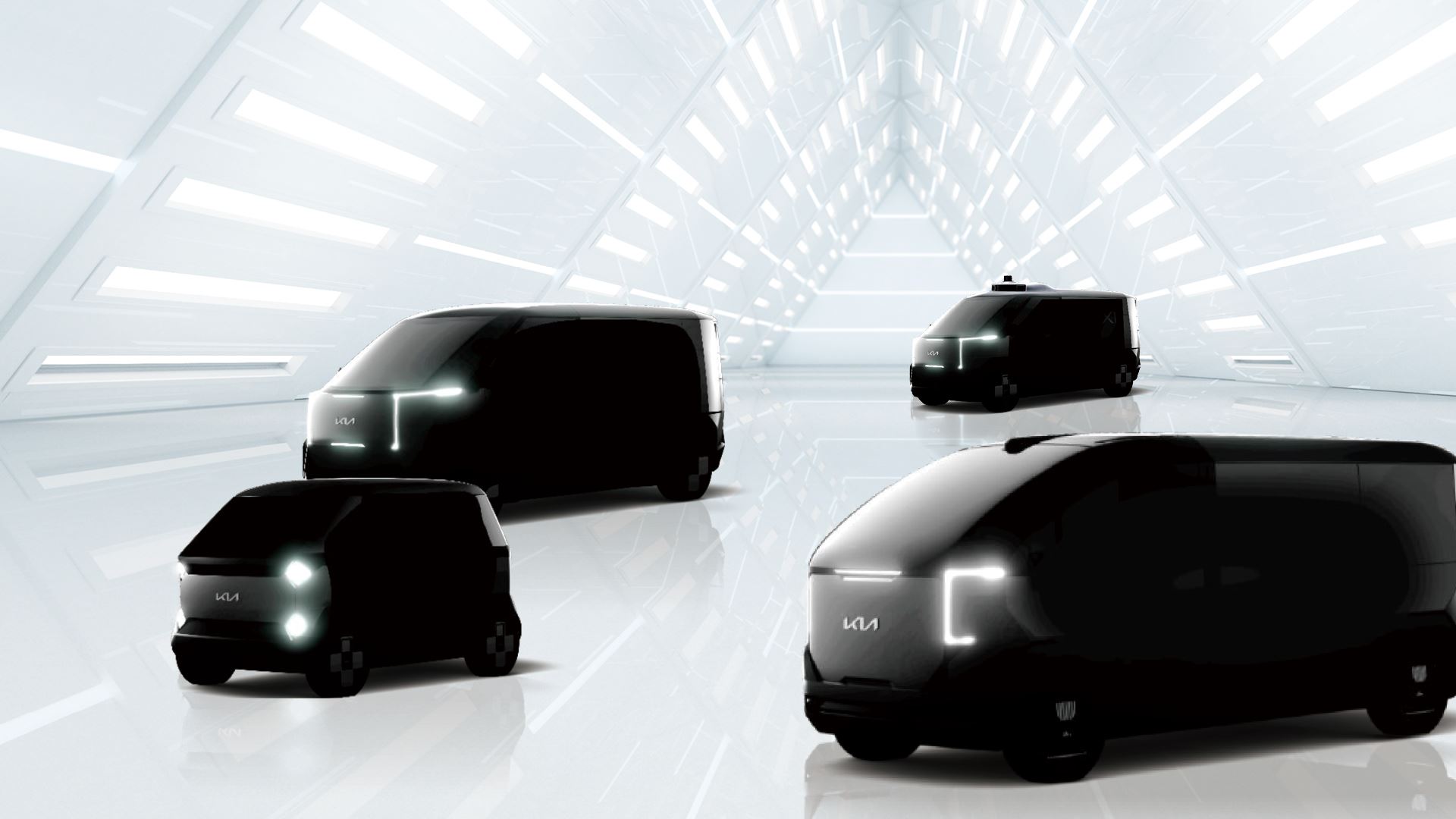

Kia’s first battery-electric PBV production is set for 2025. The company plans to show SW (project name), the first model in the company’s dedicated PBV lineup, in 2025. The mid-sized PBV model will be based on the “eS” platform, a dedicated skateboard platform for battery-electric PBVs that enables various types of vehicle bodies to be flexibly combined. SW has been developed to respond to various business demands such as delivery, ride hailing, and business-to-business (B2B) transactions thanks to its excellent load structure and spacious indoor space that reaches the height of an adult.

After launching the mid-sized SW PBV, Kia plans to expand its product lineup to large-sized PBVs that can be used for logistics, fresh food delivery, multi-seat shuttles, and mobile offices and stores, as well as small-sized PBVs and mid-sized robotaxis applied with autonomous driving technology.