ZF has inaugurated its new 800V Test & Validation facility at its research and development hub near Solihull, UK, marking the company’s first such laboratory in the country. This facility will also offer validation testing services to external parties, supporting advancements in electric vehicle (EV) technology.

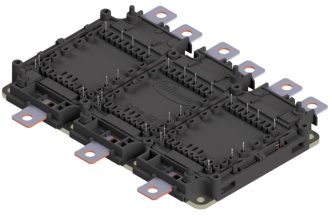

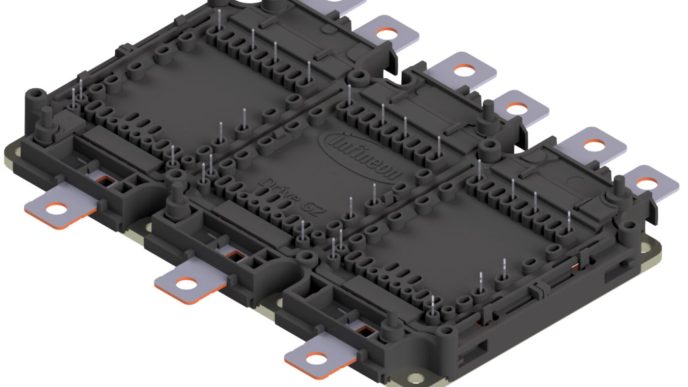

The shift from the conventional 400-volt architecture to 800 volts presents significant advantages, particularly in reducing EV charging times. ZF aims to accelerate the adoption of this technology, stating that “up to 10 percent efficiency gains are possible” when combined with Silicon Carbide MOSFETs, which may also lead to smaller battery sizes.

The facility, which spans 46 square metres, is equipped to test ZF’s own inverter architecture and will be accessible for academic projects and other organizations. One of the initial tests performed at the Solihull site involved validating a new fuel cell air compressor intended for truck and bus applications. ZF further noted that it has “more recently validated a new fuel cell Hydrogen Recirculation Blower, which the company unveiled at the IAA Transportation 2024 last month.”

The laboratory features interlocked and monitored doors, ensuring a secure environment for testing. ZF highlighted the facility’s capability to accommodate a range of components, from small modules to a full E-drive truck axle, with plans to potentially expand to support larger components in the future. The power supply, currently set to handle 1,500 VDC at 45 kW, can be increased to 90 kW as needed.

“OEMs want the compelling benefits of 800V but finding facilities capable of validating these higher-rated systems has not been easy,” said Adrian Mitcham, Head of Special Applications at ZF. He added that the company intends to provide 800V validation services to external organizations, aiming to facilitate the realization of these benefits across the broader mobility sector.