German automotive supplier ZF has introduced its latest electric vehicle (EV) technologies in a concept car based on the Porsche Taycan, showcasing their commitment to sustainable mobility. The concept car, named EVBeat, features ZF’s innovative 800-Volt electric drive, the EVSys800, as well as a proprietary central thermal management system. The launch of these cutting-edge technologies is slated for 2026.

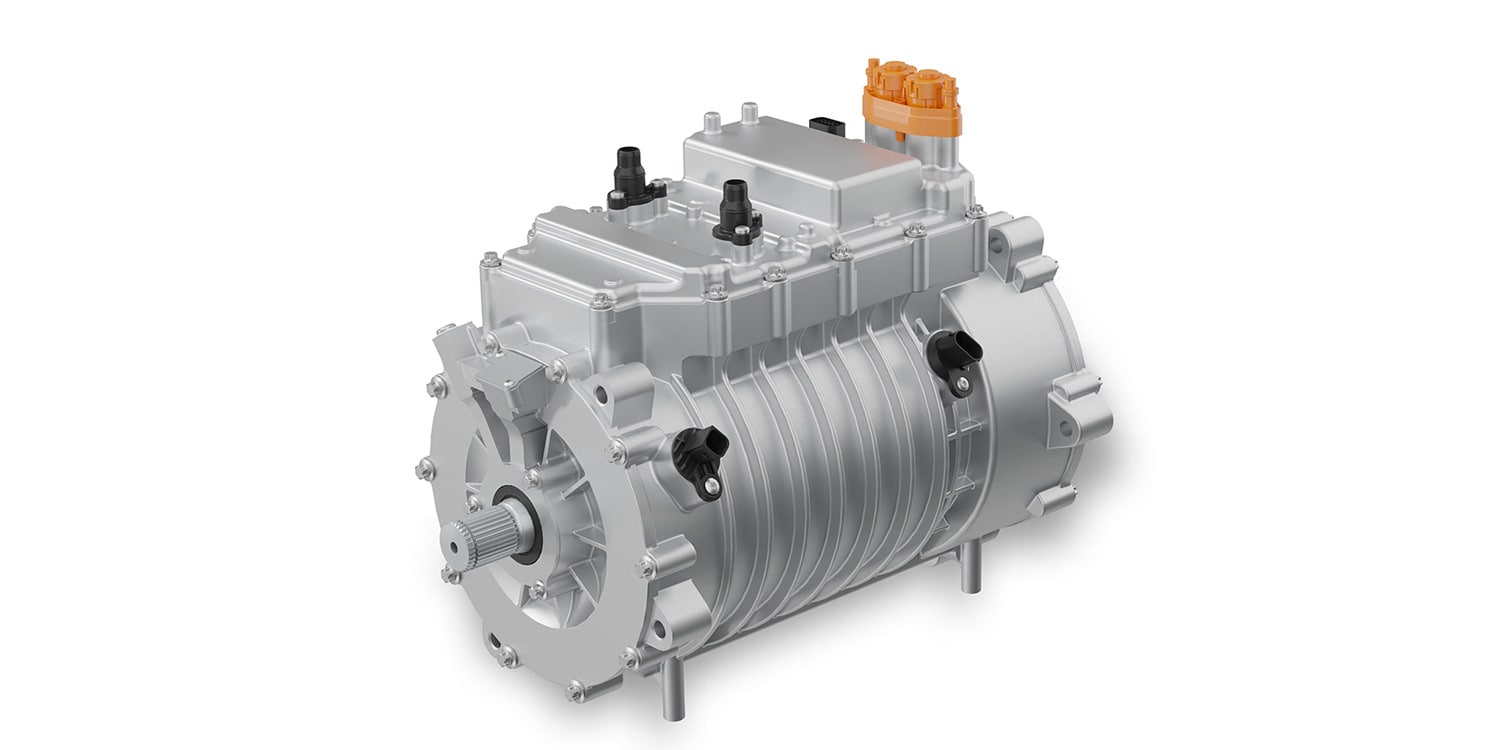

The new EVSys800 drivetrain is impressively lightweight, weighing just 74 kilograms. This makes it approximately 40 kilograms lighter than ZF’s latest 800-volt production drivetrain, contributing to the overall weight reduction of the concept car. The EVSys800 is a modular system designed for passenger vehicles, comprising a silicon carbide power electronics unit, an electric motor, and a reduction gear.

The electric motor boasts a continuous power output of 206 kW and a peak power output of 275 kW, with a torque density of 70 Newton meters per kilogram of weight. These performance features enable the concept vehicle to deliver a maximum torque of 5,200 Newton meters at the rear axle. ZF achieved these advancements through a novel cooling concept and innovative winding technology in the electric motor. The drive’s compact reduction gearbox and patented ‘Braided Winding’ save 50 millimeters in width and provide a ten percent reduction in installation space. The winding head alone is up to 50 percent smaller than conventional approaches, while direct oil cooling optimizes thermal management.

The inverter of the electric drivetrain has also undergone a fundamental redesign by ZF, resulting in improvements in electromagnetic compatibility, power modules, and capacitors. This redesign reduces size and weight, while also enhancing sustainability. Furthermore, the integration of a coaxial reduction gear improves performance by transmitting driving forces through two planetary gear sets.

ZF’s central thermal management system, named TherMaS, plays a crucial role in the EVBeat concept car. It is the first such system designed by ZF for electric vehicles and serves as the literal centerpiece of the new drive. TherMaS employs a centralized unit and software to control thermal processes for the propulsion system, battery, and passenger compartment. ZF’s design significantly reduces space requirements and weight when compared to conventional cooling and heating systems. Additionally, the inclusion of an 800-volt heat pump, which utilizes propane, contributes to energy consumption reduction.

TherMaS comprises three designated circuits, with a hermetically sealed refrigerant circuit at its core, utilizing propane as the refrigerant. Two separate coolant circuits, containing frost-resistant water, regulate the temperature of the electric machine, power electronics, and charging components. The software adjusts cooling performance based on demand, enabling higher continuous power output from the electric machine.

According to ZF, this comprehensive thermal management system enhances the range of the EVBeat by up to a third during demanding winter conditions.

Another noteworthy innovation is ZF’s cloud-based drive software, specifically developed for the modified Porsche Taycan. This powertrain software establishes a network among all vehicle systems and connects them to the cloud. While the hardware provides a solid foundation for the sustainable operation of the vehicle, the software ensures their optimal orchestration. By analyzing individual driving profiles and utilizing cloud-based artificial intelligence, the software adapts to driver behavior, resulting in improved overall performance.

The software is designed to maintain thermal operating points within the optimum range at all times, as the efficiency of an electric motor depends on it. ZF explains that the optimum thermal operating point is very low at low speeds and high torque requirements, while high temperatures are not problematic during high-speed, low-torque situations. Since thermal conditions cannot be established immediately, ZF programmed the software to anticipate the optimum operating points based on individual driving profiles. The system “learns” drivers’ behavior and predicts the probability of personal driving profiles using an AI-based cloud service. For instance, air conditioning and system cooling are reduced when short distances are detected.

Stephan von Schuckmann, a member of the ZF Board of Management, stated, “Sustainable mobility is at the core of our corporate strategy. Based on an extremely efficient production vehicle, we are showing the potential that future electric drive components offer when we combine them into an even more efficient overall system.”

Dr. Otmar Scharrer, Head of Development for Electric Driveline Systems at ZF, highlighted the ability of the new system to meet the main requirements of their customers, namely efficiency, performance, and cost-effectiveness.

The market can expect the first technologies of ZF’s new driveline to be available in 2026, marking a significant step towards advancing electric mobility and ushering in a new era of efficient electric vehicles.