German-Australian firm Vulcan Energy has successfully produced lithium hydroxide at its facility in Frankfurt-Höchst, marking what the company describes as Europe’s first sustainable lithium production process, spanning raw extraction to final product.

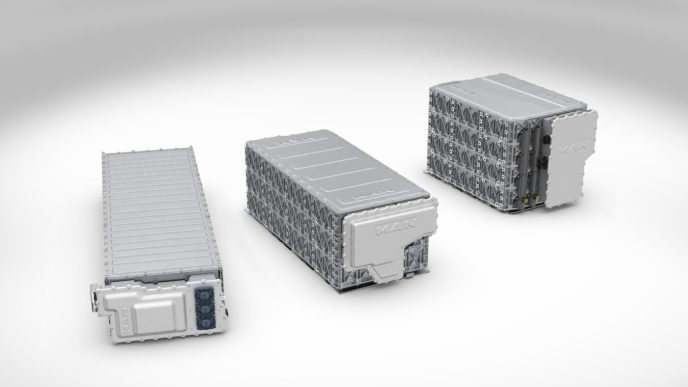

Vulcan Energy’s approach involves extracting lithium from geothermal brine, establishing a European supply of this essential battery material. The company operates one of Europe’s largest geothermal and lithium resources, primarily located in Germany’s Upper Rhine Valley. According to a February 2023 feasibility study, Vulcan’s initial production goal is set at 24,000 tonnes of lithium hydroxide monohydrate (LHM) per year, utilizing lithium chloride through a multi-stage refinement process.

To advance toward commercial production, Vulcan has established two test plants in Germany. The LEOP (Lithium Extraction Optimisation Plant) in Landau began filtering lithium chloride from geothermal brine in April, followed by the CLEOP (Central Lithium Electrolysis Optimisation Plant) in Industriepark Höchst, which further processes the lithium into battery-grade lithium hydroxide.

In a statement, Vulcan highlighted that these processes create an integrated supply chain and enhance Europe’s access to local critical resources. The LEOP and CLEOP test plants will continue to refine the process, operating at a reduced scale (1:50) compared to the planned commercial facility, the Central Lithium Plant (CLP), also set for Industriepark Höchst.

The lithium hydroxide produced will undergo validation by Vulcan’s partners, including Stellantis, Renault, LG, and Umicore, in the initial project phase. Vulcan states that the extraction and production processes avoid fossil fuel use, instead relying on renewable heat and green electricity, contributing to a low carbon footprint and reduced transportation emissions for its European partners.