Volvo Cars has signed a memorandum of strategic cooperation with Contemporary Amperex Technology Co Ltd (CATL) to collaborate on battery recycling, aiming to reduce the carbon footprint of electric vehicles (EVs) throughout their life cycle.

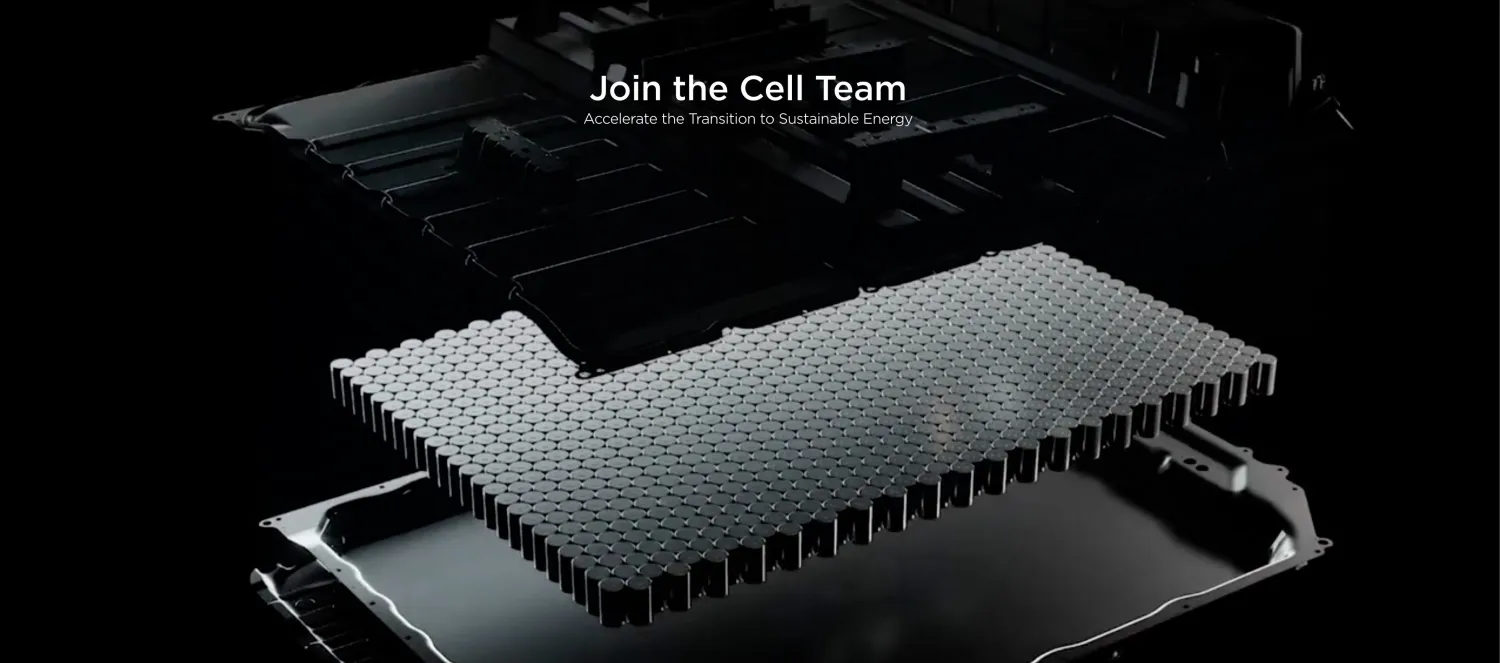

The partnership seeks to promote the recycling of battery materials, addressing the environmental challenges posed by the disposal of retired batteries, which can contain non-renewable metal elements. Volvo stated that carbon emissions from mining and processing these materials account for a significant portion of the battery production cycle.

With the rapid growth of China’s EV market, a large number of power batteries are expected to reach the end of their life, posing environmental challenges if not properly disposed of. Volvo and CATL aim to reduce EV full life cycle carbon emissions by dismantling, recycling, and reusing used batteries.

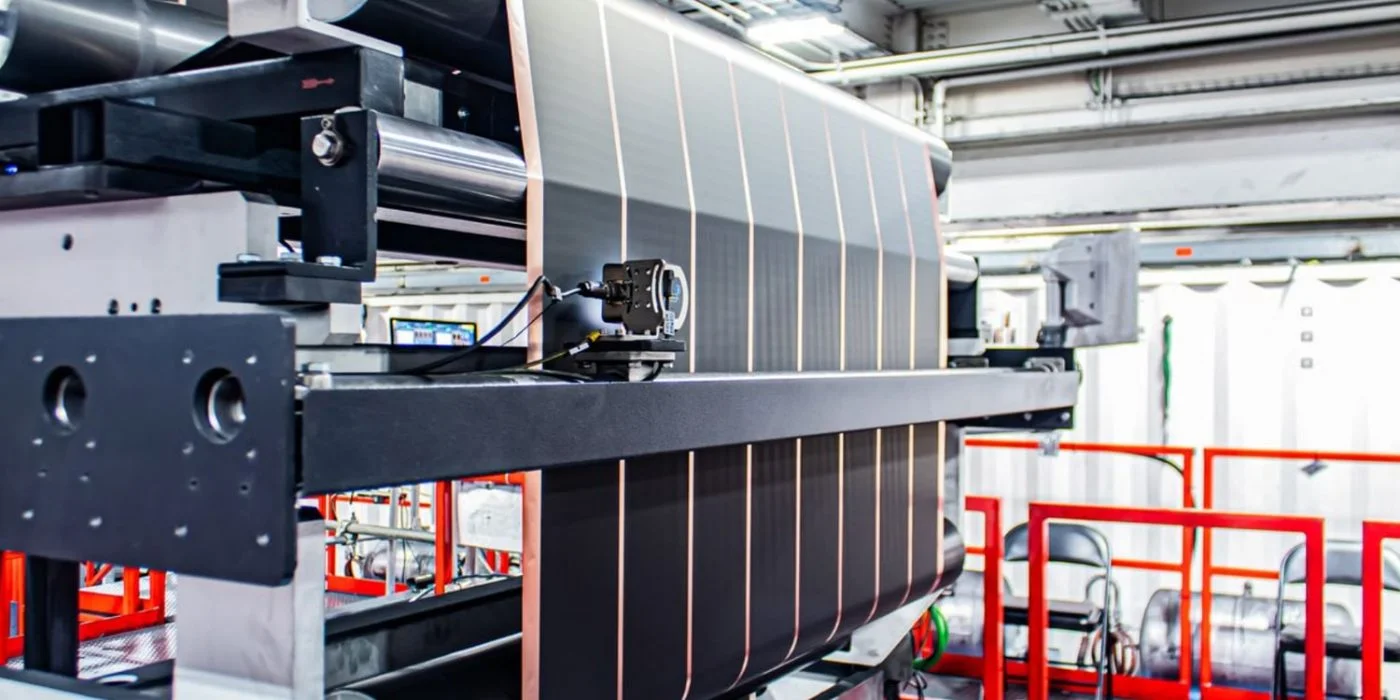

Under the agreement, Volvo will recycle retired batteries from its sold EVs and those scrapped during factory production. Certified suppliers will dismantle these batteries to extract more than 90 percent of nickel, cobalt, lithium, and other metal materials. CATL will then use these recycled materials to produce new batteries for use in new Volvo vehicles.

Tan Libin, co-president of CATL’s marketing system, described the partnership as an important milestone in building a battery recycling, closed-loop business model in China, opening a new chapter in the closed-loop management of the battery cycle.

Volvo unveiled its sustainability strategy in 2019, aiming to reach an average of 30 percent recycled material use across its entire model range by 2030. Additionally, Volvo aims to include at least 35 percent recycled materials in new models produced from 2030 onwards.

Li Hai, vice president of supply chain for Volvo’s Asia-Pacific region, emphasized the company’s commitment to achieving net-zero greenhouse gas emissions by 2040, highlighting the need for a concerted effort from supplier partners across the chain.