Volkswagen, the German automaker, is undertaking a significant reorganization of its production operations in China. The company plans to create space for the production of electric vehicles (EVs) by consolidating its manufacturing processes. As part of this restructuring, the assembly of combustion models will be relocated from the Anting plant to other facilities.

The German publication Handelsblatt, citing a company spokesperson, reported on these changes. While specific details about the reorganization remain limited, it is confirmed that SAIC Volkswagen’s main plant in Anting will be restructured from its current four-part setup to a three-part configuration.

Volkswagen made these plans public in response to speculation on social media platforms in China regarding the closure of the Anting factory. However, it is still unclear where the internal combustion engine production will be relocated from the Anting plant. Volkswagen has assured that this move will not impact the production capacities of individual models and emphasized its commitment to accelerating the transition to e-mobility.

The move comes as Volkswagen faces a decline in its market share in China. In 2022, the automaker delivered only 3.18 million vehicles (across all drive types) in the country. Handelsblatt highlights that Volkswagen’s plants in China have not been operating at full capacity due to the impact of the COVID-19 pandemic. According to data from industry service Marklines, the SAIC plants alone have the capacity for approximately 2.27 million vehicles annually. However, last year’s production only required capacity for about 1.34 million cars.

Recently, Volkswagen announced the establishment of a new development center for electric cars in Hefei, China. The aim of this facility is to expedite the introduction of new EVs to the Chinese market, aligning them with the preferences and requirements of Chinese customers. The company plans to invest around one billion euros in this project. Described as more than a traditional research and development center, it will serve as a “new center for development, innovation, and procurement for fully networked electric cars,” according to Volkswagen’s headquarters. The new venture, known as “100%TechCo,” will integrate vehicle and component development, as well as procurement, resulting in a 30% reduction in the development time for new products and technologies, according to Volkswagen.

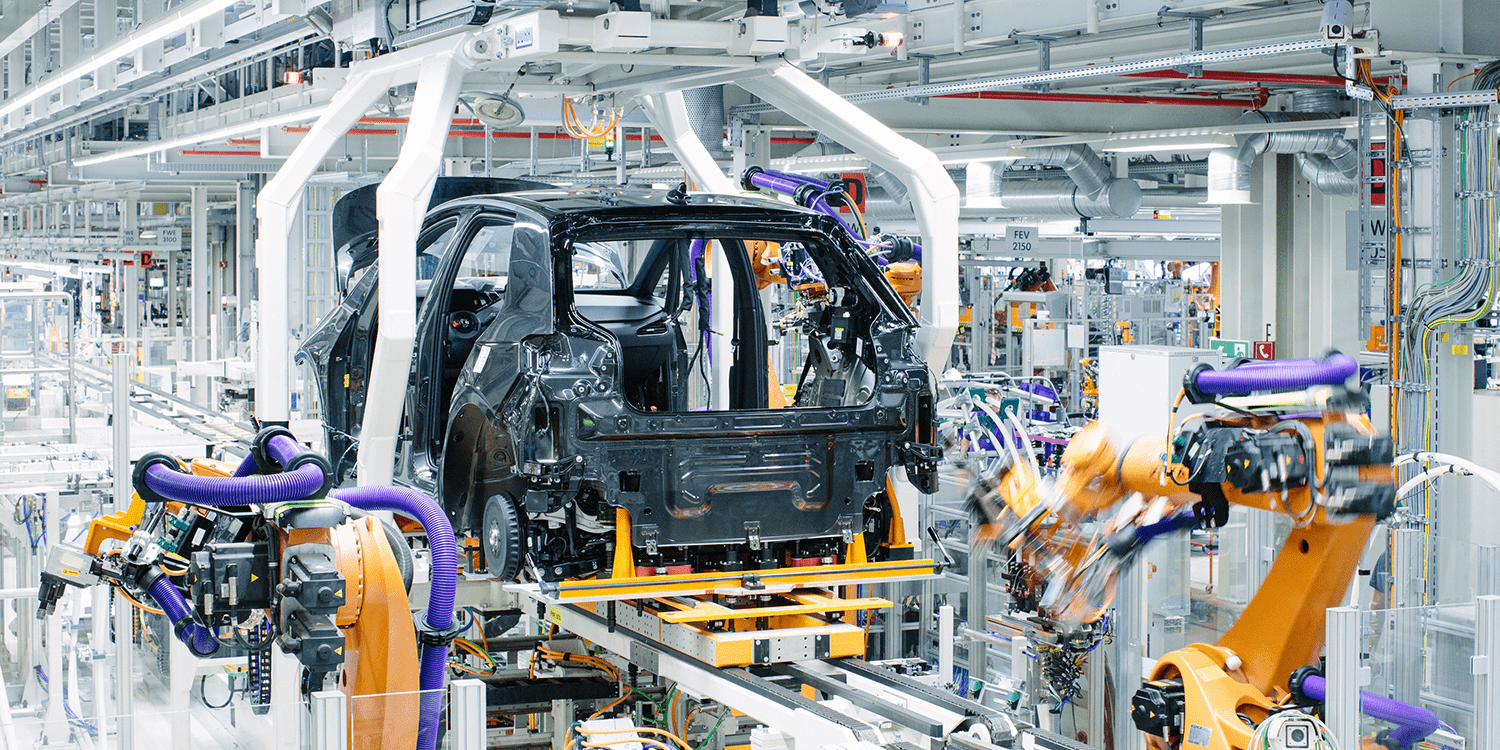

Currently, the Volkswagen Group produces electric cars based on the MEB platform in three Chinese factories: Anting (SAIC-VW), Foshan (FAW-VW), and Anhui (formerly JAC-VW) since 2022. The Anhui facility stands out from Anting and Foshan as Volkswagen took over the majority of the JAC-Volkswagen joint venture in 2020, rebranding it as Volkswagen Anhui. Consequently, Volkswagen has full control over the plant, distinguishing it from its partnerships with SAIC and FAW. The Anhui plant is also recognized as Volkswagen’s most automated facility in China, with over 900 robots deployed across its expansive 140,000 square meters.

Volkswagen’s reorganization in China signifies its commitment to adapt to the evolving automotive landscape and meet the increasing demand for electric vehicles. By consolidating its production processes and investing in development centers, the company aims to enhance its competitiveness in the Chinese market while furthering the transition towards e-mobility.