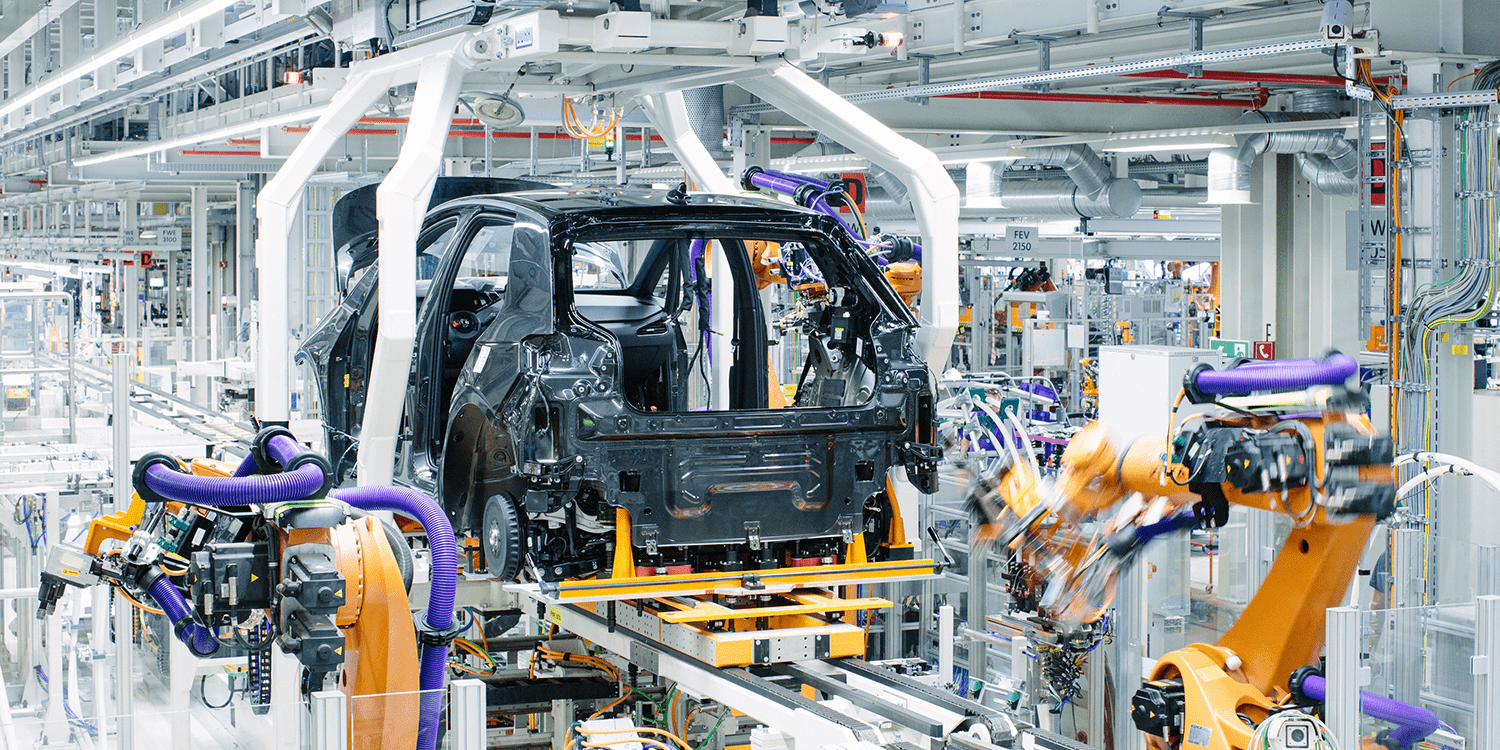

In response to weakening sales, Volkswagen has announced a temporary reduction in the production of electric cars at its Emden plant, according to the works council. The decrease in demand has affected not only the ID.4 model but also the production start-up of the new electric sedan, ID.7.

Citing information from the works council, a report in the local German publication Nordwest-Zeitung confirmed that demand for Volkswagen’s electric vehicles is nearly 30 percent below the initially planned production figures. The works council further revealed that the late shift for the production of the ID.4 and the initial models of the ID.7 will be canceled in the next two weeks leading up to the plant holidays. Additionally, the plant holidays, which typically last three weeks, will be extended by an extra week for workers in the E-segment. Moreover, around 300 temporary workers out of the current 1,500 employed in Emden will not have their contracts renewed starting from August.

Initially, Volkswagen had intended to introduce a third production shift for the E-models in the autumn. However, the works council informed the staff about the revised plans on Monday. It should be noted that the production adjustments will solely impact the electric car production at the Emden plant, while the production of the Passat will continue unaffected.

As a consequence of the reduced production, Volkswagen has decided to postpone the official ceremony marking the start of ID.7 production in Emden. While production of the model has commenced as scheduled, only a few examples are currently being manufactured in advance. The new date for the ceremony has yet to be announced.

The decrease in production is primarily attributed to low demand. Manfred Wulff, a member of the Emden works council, noted that customer hesitation is significantly impacting the electric car market. There is widespread uncertainty among customers, which has also led to disillusionment among the workforce following Monday’s announcement.

Volkswagen has refrained from commenting on the demand for specific models but remains optimistic about the upcoming launch of the ID.7. A spokesperson for the company expressed confidence in the plant’s future utilization, stating, “We are confident that the utilization of the plant will increase again with the market launch of the ID.7 at the end of the year.” It’s important to note that Emden is currently the sole production plant for the ID.7.

The situation differs for the ID.4 model, as the MEB SUV is still being manufactured in Zwickau, Europe. Initially, ID.4s for the US market were produced in Germany and exported, but since the start of ID.4 production at the US plant in Chattanooga, exports from German plants have ceased. ID.4 production began in Emden in May 2022, while production in Chattanooga commenced in July of the same year. As a result, ID.4 production capacities have significantly increased within a two-month period. Notably, this does not account for production in China, which is exclusively intended for the local market.

Olaf Lies, Lower Saxony’s Minister of Economics and member of VW’s supervisory board, deemed the decision understandable while highlighting its significance as a “warning signal for the industry.” Referring to the decline in subsidies, Lies expressed concerns about the current dip in demand, emphasizing that it extends beyond Volkswagen and affects all manufacturers. The politician suggested considering new purchase incentives, such as reduced value-added tax, to stimulate demand.