German automaker Volkswagen is setting its sights on implementing a groundbreaking production process for electric car batteries on a large scale. By utilizing a dry coating technique, Volkswagen aims to reduce energy consumption in battery cell production by 30 percent and significantly lower the costs of electric vehicles by several hundred euros per unit.

According to a report by German publication Spiegel, Sebastian Wolf, a board member of Volkswagen’s battery subsidiary PowerCo, unveiled the company’s ambitious plans. Volkswagen intends to ascend the value chain by producing cells for future electric car batteries in their own large-scale manufacturing plants.

Internal tests have proven the viability of the electrode dry coating method, leading PowerCo to invest further in the process. A pilot line will be installed in a laboratory near Salzgitter, Germany, where PowerCo is currently establishing its first battery cell factory worldwide. Wolf stated that Volkswagen, in collaboration with partners, has been researching this innovative process since 2020, with the aim of applying it to millions of battery cells by the beginning of 2027. The project’s total costs to date are estimated to be around 40 million euros.

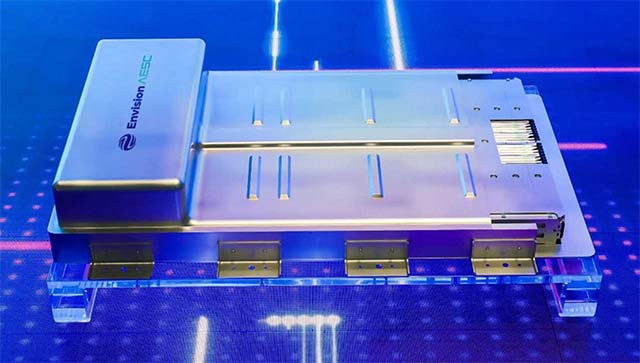

Dry-coating processes for electrodes are being explored by several companies and research institutions globally. The electrode, a vital component of the battery, typically consists of a metal foil covered with a thin coating containing active components responsible for energy storage. Traditionally, the coating process involves wet-chemical methods using paste-like mixtures, requiring lengthy drying periods to evaporate the solvent. The introduction of dry coating eliminates the need for these steps, streamlining the production process.

One notable alliance actively involved in this field includes Siemens, LiCAP Technologies, and BW Papersystems. They recently formed a strategic partnership to manufacture and market equipment for the battery cell industry capable of dry coating. Tesla is also pursuing dry coating for its large 4680 cells, although reports suggest it is encountering challenges with the cathode’s dry coating process.

Volkswagen is not only focused on the dry coating process but is also looking ahead to future production systems. In 2021, the company invested in the US battery start-up 24M Technologies, which specializes in a semi-solid process that surpasses dry coating. As a licensee of 24M Technologies, Volkswagen aims to achieve significant cost optimization in battery production by reducing material usage and eliminating various steps in the conventional production process. A Volkswagen subsidiary will further develop and scale this technology based on 24M’s patent rights for automotive applications.

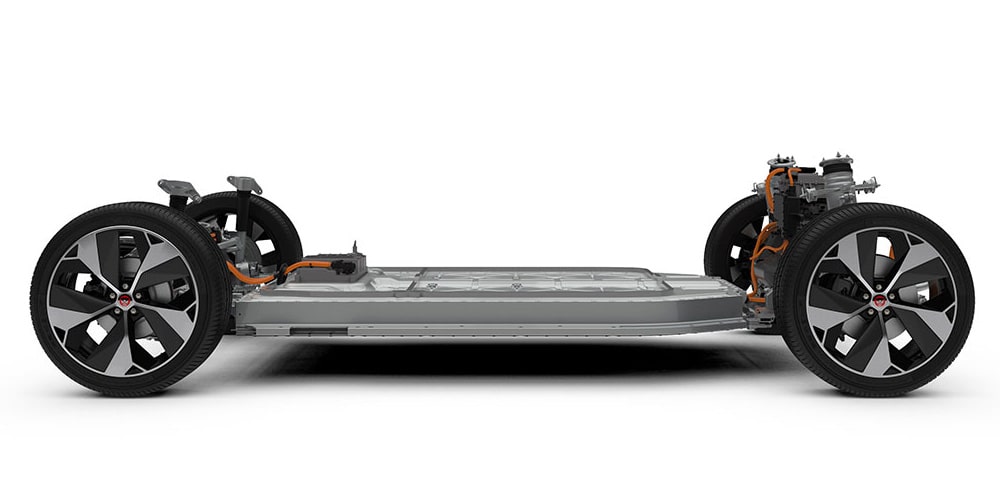

The company has identified potential benefits of the solid-state technology, including up to a 40 percent reduction in production space, substantial cost savings, improved product recycling efficiency, and a positive impact on the CO2 emissions associated with battery production. The introduction of this process on a large scale was initially planned for the second half of the decade. While the current status of that timeline remains uncertain, the recent developments surrounding the dry coating process indicate that Volkswagen is committed to advancing battery production techniques.