In response to the surging demand for electric vehicles (EVs) and the critical need to reduce carbon emissions, the United Kingdom is embarking on an ambitious venture. The nation is set to construct Europe’s inaugural and largest lithium refinery, a move aimed at providing a steady supply of this sought-after mineral while significantly curbing its carbon impact.

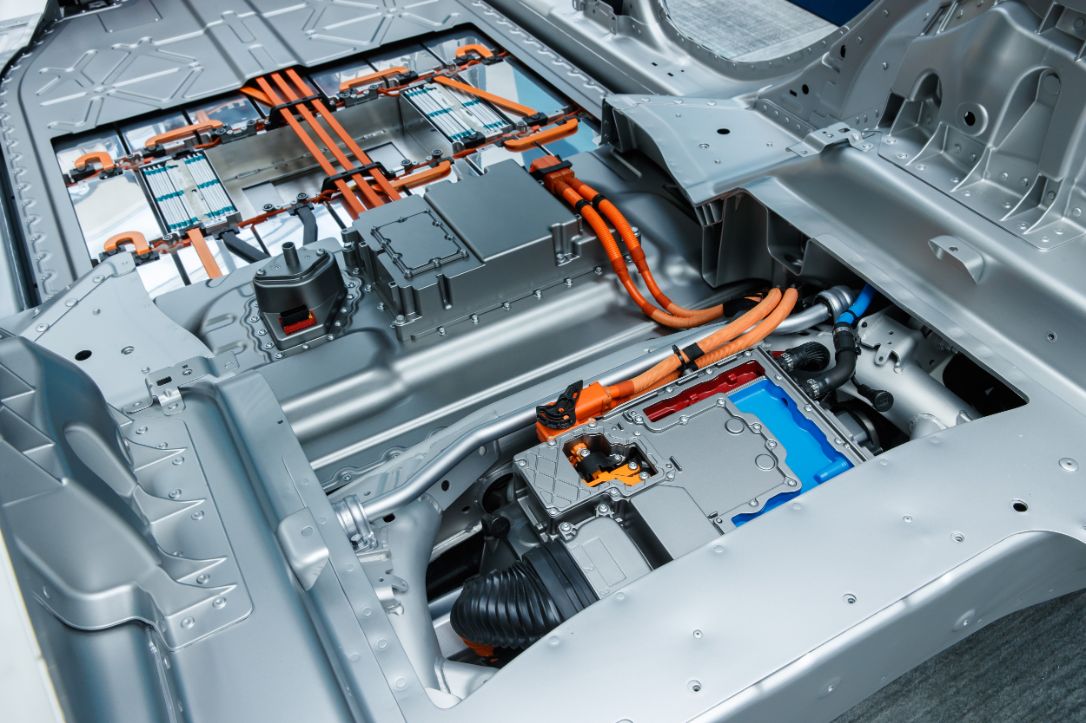

The global shift towards renewable energy sources has ignited a frenzy for lithium, a pivotal component in the production of EV batteries. As the planet rallies behind sustainability goals, the demand for the ore metal has escalated dramatically. It’s projected that up to 60 percent of new vehicle sales by 2030 will be comprised of EVs, each reliant on lithium-ion batteries. For instance, the battery of a Tesla Model S currently necessitates around 12 kilograms of lithium.

See also: Japan’s Idemitsu to close Yamaguchi oil refinery facility as cars go electric

Presently, however, the majority of the world’s refined lithium hails from East Asia, predominantly China, responsible for 89 percent of global output. This dependence on a singular region for lithium supply poses challenges for the burgeoning electric vehicle industry.

Addressing this concern, the UK government has granted the green light to Green Lithium, a UK-based company, to establish a refinery in Teesside, England. This strategic move is anticipated to invigorate the local and European automobile manufacturers.

Sean Sargent, the CEO of Green Lithium, emphasized the compelling necessity for growth in battery materials to power the electric revolution. “We think by 2030 we’re going to need about 800,000 tonnes per annum,” stated Sargent, referring to the mounting demand for battery chemicals in Europe.

The planned refinery, slated to commence operations in 2027, is poised to possess an annual production capacity of 50,000 tonnes of battery-grade lithium chemicals. This quantum leap in supply could furnish batteries for up to one million EVs. The establishment’s modus operandi revolves around processing spodumene, a hard rock mineral imported from Western Australia, to extract and refine lithium suitable for battery use.

While the process of lithium mining often bears the detrimental impact of air pollution and soil contamination, Green Lithium is making strides to mitigate such concerns. The company intends to revolutionize lithium refining by adopting low-energy procedures, harnessing renewable electricity, integrating hydrogen gas, and deploying carbon capture technology. By doing so, Green Lithium seeks to achieve an impressive 80 percent reduction in the carbon footprint associated with traditional refineries.

Sargent underscored the overarching environmental benefits of their approach, highlighting that even with the logistical overhead of shipping materials to the UK, the subsequent reduction in carbon emissions far outweighs the costs. “So, straight away we start with a huge dividend in carbon reduction, but we’re also producing our chemicals sustainably,” Sargent affirmed.

In an era where sustainable practices are paramount, the establishment of Europe’s first lithium refinery stands as a testament to the innovative solutions that can drive the EV sector towards a greener future. With the promising prospect of diminished carbon footprints and enhanced battery supply, the Teesside refinery could very well become a pivotal milestone in the journey towards sustainable transportation.