Tesla, the electric vehicle giant, has recently hired a battery manufacturing expert, Matt Tyler, to help the company overcome the challenges it has been facing with its dry electrode project. According to Electrek, Tyler has over a decade of experience working on battery cells, and most recently, he held the role of Vice President of Advanced Manufacturing at 24M, a battery manufacturer that specializes in “semisolid electrodes” for lithium-ion batteries.

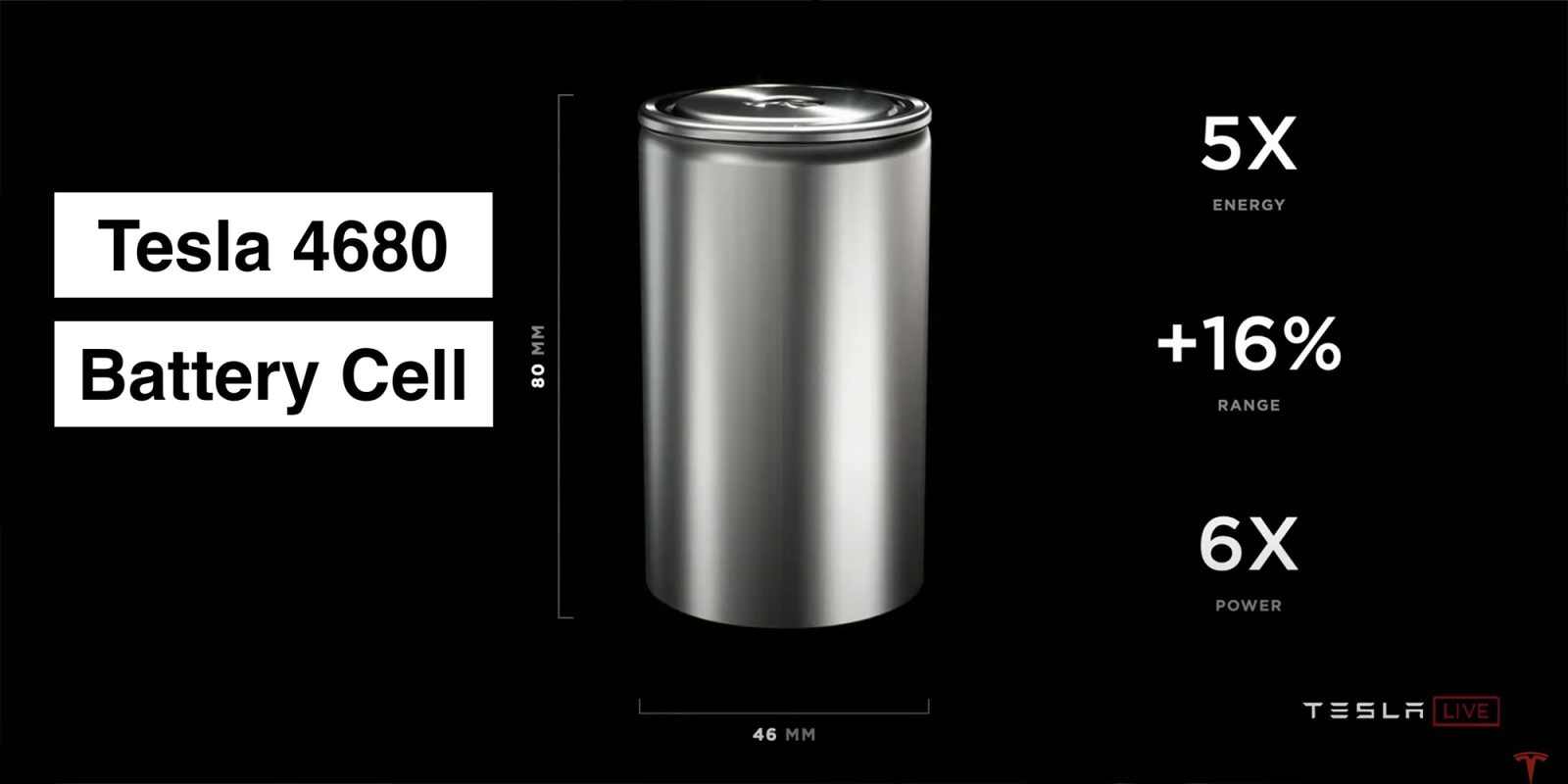

Tyler’s expertise in developing “semisolid electrodes” is particularly relevant to Tesla’s dry electrode project, which the company acquired through its acquisition of Maxwell. The dry electrode technology is a key advancement in battery cell manufacturing, and Tesla claims that it can significantly reduce the manufacturing footprint and energy usage by 10 times. This reduction could result in significant cost savings for the company and enable it to scale production of its 4680 battery cell.

However, the dry electrode technology has been identified as one of the main bottlenecks for Tesla’s 4680 battery cell production. The technology needs further development before Tesla can ramp up production to high volume. Recent teardowns of Tesla’s 4680 cells in Model Y vehicles showed that the dry electrode factor is still not where Tesla needs it to be.

Tyler’s appointment suggests that Tesla is committed to solving the dry electrode challenge and ramping up production of its 4680 battery cell. His LinkedIn profile reveals that he was responsible for managing the development of semi-solid lithium-ion battery manufacturing engineering, leading the overall manufacturing concept design, equipment vendor/partner selections, in-house equipment and tooling development, and process development to be competitive in cost and product quality in the lithium base rechargeable battery market.

Regarding his previous role, Tyler wrote on his LinkedIn profile, “Working closely with the VP Product Development to select and implement analytical equipment, as well as design and develop processes to meet the tolerances defined in product and process specifications. Also working closely with Director of Product Launch, and the Director of Operations, to define and execute against milestones and product delivery schedules.”

Tyler’s experience in developing semi-solid lithium-ion battery manufacturing engineering, coupled with his responsibilities at 24M, make him an excellent addition to Tesla’s team. His appointment demonstrates Tesla’s commitment to improving its battery cell manufacturing technology and achieving its goal of producing more efficient and cost-effective electric vehicles.