A semiconductor shortage has become a nightmare for automakers worldwide, and sadly there is no sign that this crisis will end anytime soon.

However, starting in 2024, this problem will see a gradual recovery, mainly thanks to massive investments in production capacity.

In other words, after two or three years of planning and millions of dollars ready to be poured into new factories and equipment, the chip industry should certainly be able to produce enough semiconductors for the automotive market.

Sony also seems to want to help overcome this problem, the company from Sakura Country recently decided to invest no more, no less than $ 70 million for the creation of a new semiconductor factory in Thailand.

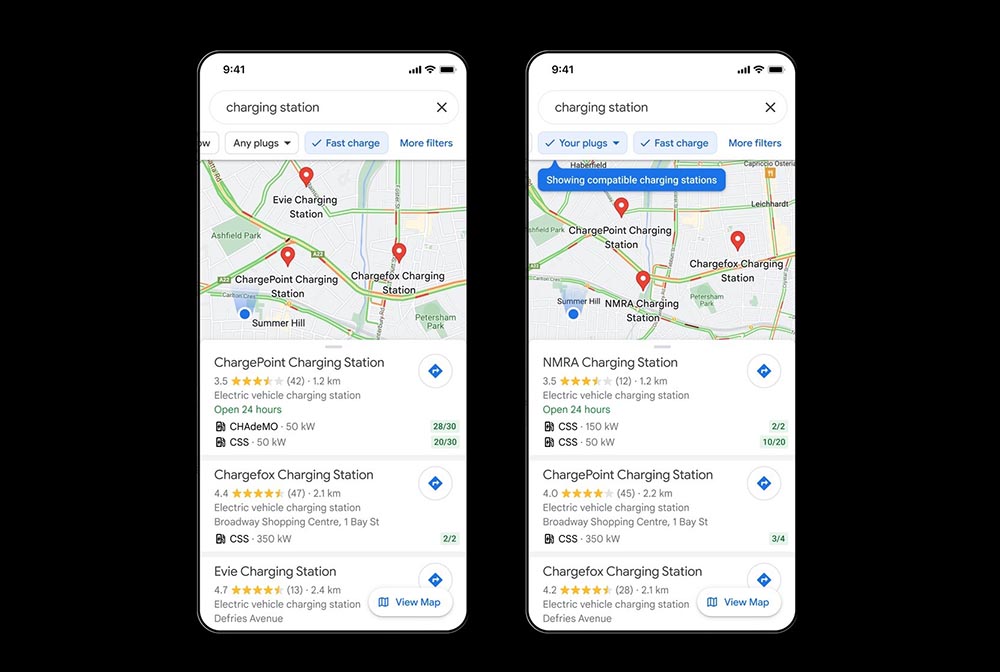

According to reports, the new facility will be responsible for manufacturing image sensors specifically intended for technologies installed in new generations of vehicles, including here self-driving vehicle models.

Image sensors will be used to automatically identify pedestrians and obstacles, and Sony believes this could be one of the most important factors in this area.

Sony aims to supply the new chips to automakers from around the world, with the factory to employ at least 2,000 people, starting with the fiscal year ending March 2025.

For Sony, this investment is a major step towards expanding its operations in Thailand. When the new production plant is operational, the company’s local manufacturing strength will grow by as much as 70 percent.

In the long term, the new factory in Thailand will help increase image sensor production and help Sony grow in the automotive industry, although the company will still rely on multiple facilities to complete the process.

For example, the new factory in Thailand will be tasked with producing chips using “wafers” it receives from Sony’s factory in Japan, but the parent company hopes local operations will grow to become a key part of its global production network.