Electric vehicle manufacturer Rivian has reportedly undergone a substantial restructuring within its long-range battery cell development team, leading to the departure of approximately 20 team members, including lead cell engineer Victor Prajapati—a former senior manager at Tesla. This development has sparked speculation regarding Rivian’s future plans for in-house battery production.

Currently headquartered in California, Rivian sources its battery cells from Samsung SDI in South Korea, integrating them into packs at its manufacturing facility in Normal, Illinois. The decision to streamline the battery cell development team has raised inquiries about the company’s earlier commitments to manufacture its own batteries at a forthcoming facility in Georgia, potentially indicating an increased reliance on third-party suppliers (via The Information).

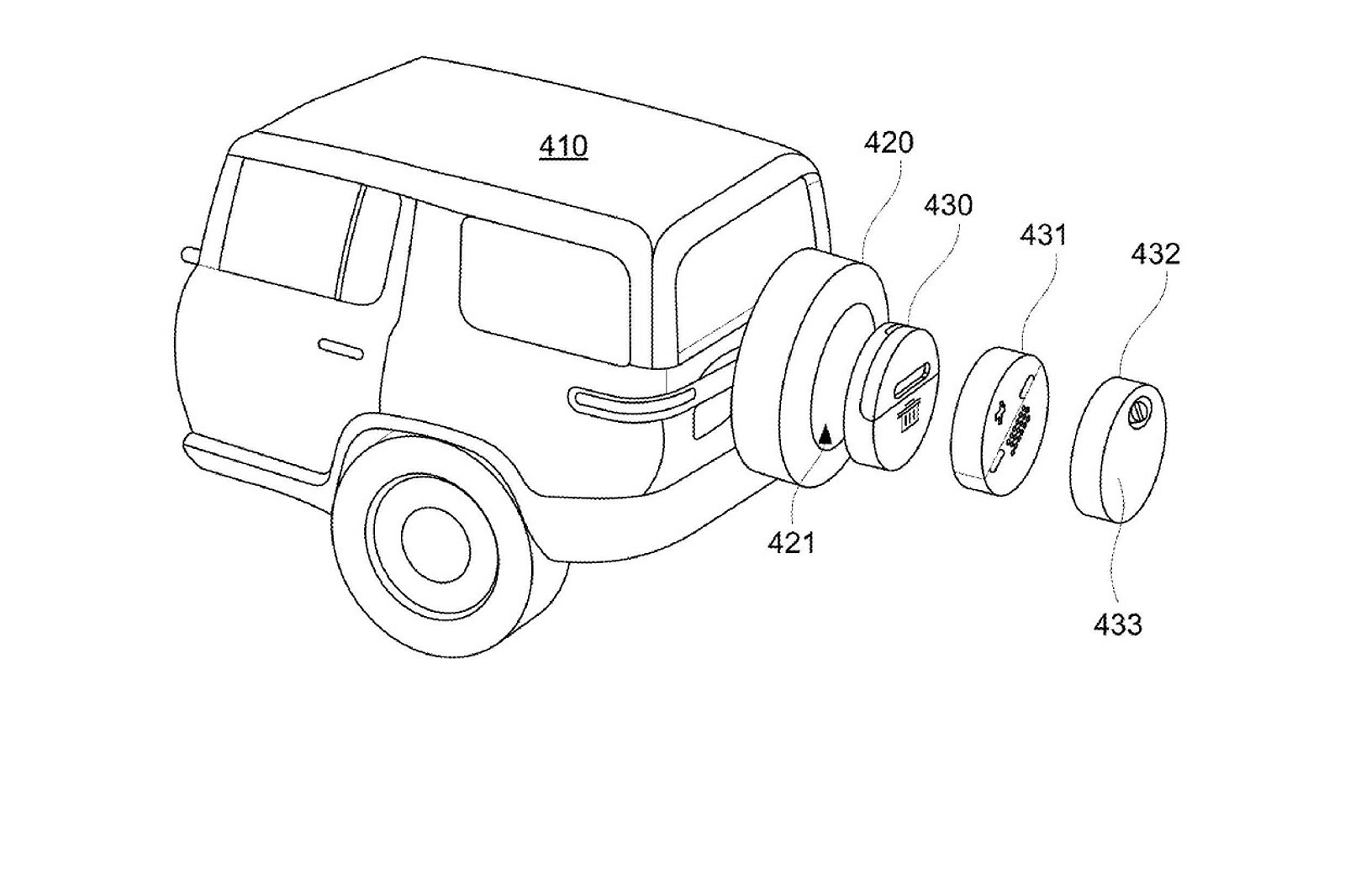

Scheduled to commence production of Rivian’s R2 platform in 2026, the Georgia-based factory is anticipated to unveil a prototype soon. The R2 platform’s initial release is expected to feature a smaller SUV in the $50,000 price range. Simultaneously, Rivian has disclosed plans to incorporate lithium-iron-phosphate (LFP) cells for entry-level batteries and delivery vans, aiming to enhance affordability.

In November, Rivian revised its production forecast, surpassing earlier guidance by aiming to deliver 54,000 vehicles in 2023, up from the initial projection of 52,000 deliveries. The company also announced alterations to its exclusivity agreement with Amazon, permitting the sale of commercial vans to other customers.