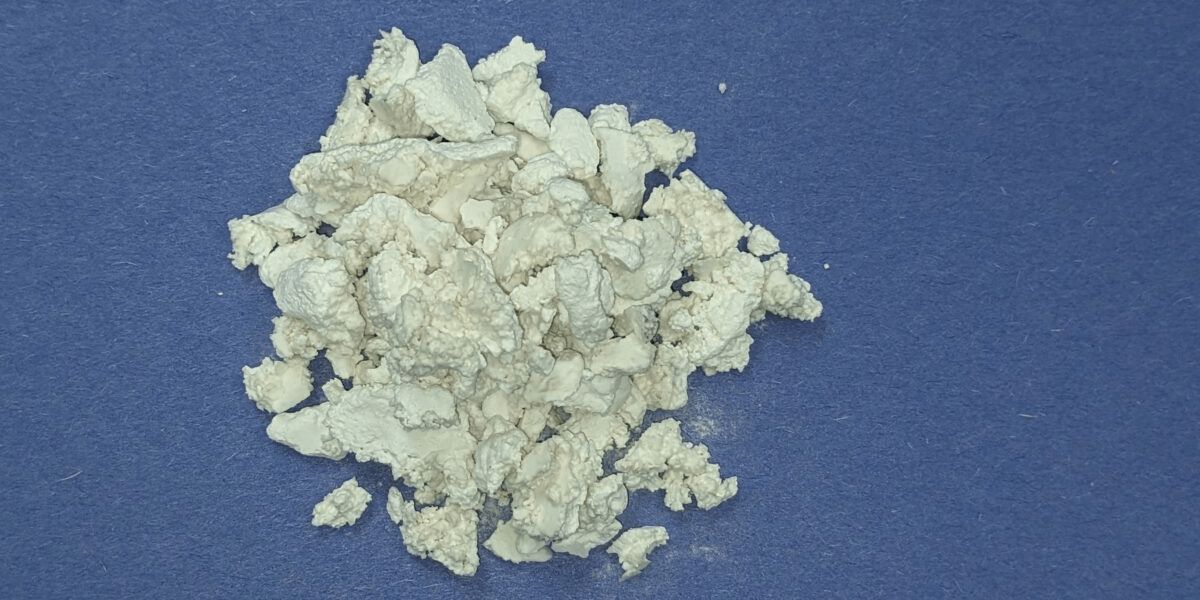

A research team at TU Bergakademie Freiberg in Germany is utilizing a new shredder plant to enhance the efficiency of battery cell recycling, aiming to maximize the recovery of valuable raw materials. This initiative seeks to make battery recycling more economically viable by employing a shredder capable of processing used battery cells weighing up to 2.5 kilograms in a single step, producing particles ranging from 0 to 20 millimeters, particularly fine particles known as black mass. This black mass contains essential materials such as nickel, cobalt, and lithium.

Professor Urs Peuker, Director of the Institute of Mechanical Process Engineering and Processing Technology, emphasized the goal of recovering these materials as completely as possible. The upcoming revisions to the European Battery Regulation, expected to take effect between 2027 and 2031, will require improved standards for the disposal and recycling of battery waste. Ensuring the quality of the black mass while minimizing contamination from other battery components is crucial to this effort. The new shredder technology facilitates extensive experimental studies to optimize the quality of the black mass.

The shredder system incorporates sensors and cameras to monitor processes, and it is equipped with online capabilities to compile results in a specialized research database. This database integrates findings from the shredder along with data from TU Bergakademie and its partners, including the Helmholtz Institute Freiberg and Fraunhofer THM.

This innovative shredder technology is versatile, applicable to batteries from power tools and e-bikes, as well as larger cells from electric and hybrid vehicles. Additional processing steps such as sieving, sifting, and magnetic separation further refine the black mass.

The system’s closed design allows for the recovery of volatile electrolytes released during shredding, enhancing process reliability and overall recycling rates. The research facility was acquired through the ‘InfraDatRec’ project, receiving approximately 7 million euros in funding from the Federal Ministry of Education and Research until September 2024.

Initial tests commenced in the summer, and future enhancements will incorporate new sensors to connect the shredder system to databases for data analysis using artificial intelligence. Professor Peuker noted the increasing complexity of battery recycling, stating that traditional methods are becoming insufficient. He highlighted the importance of live data acquisition, big data, and AI in developing and demonstrating advanced recycling technologies, particularly in the context of electromobility, a vital industry for Saxony.