Redwood Materials has achieved notable progress at its Nevada campus. Over the past year, the company has intensified its hydrometallurgical operations, inaugurated a large-scale recycling rotary calciner, and commenced production of battery anode copper foil.

These developments signify a pivotal advancement in Redwood’s mission to create a sustainable source of battery materials for the domestic electric vehicle industry. The company’s hydrometallurgical facility, the first commercial-scale nickel “mine” to open in the US in years, not only recycles battery scrap but also represents a new source of domestic lithium supply.

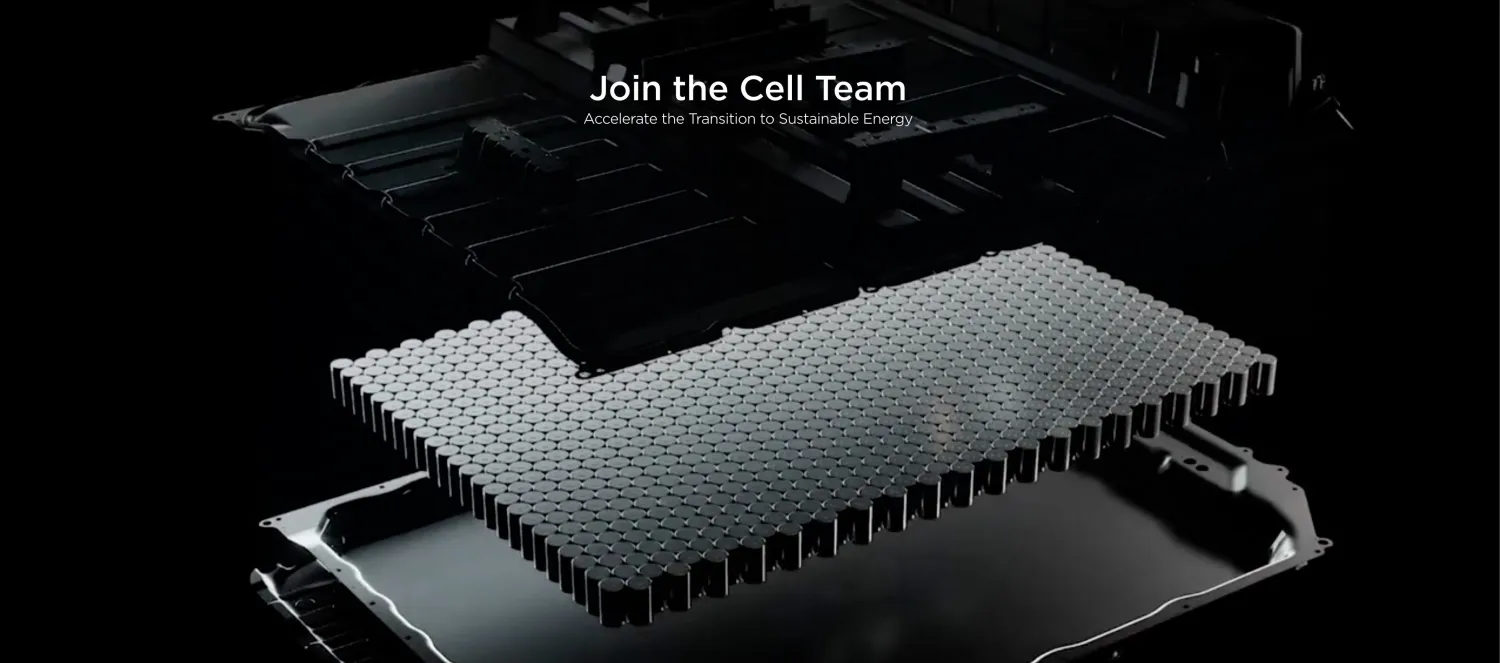

Emphasizing environmental responsibility, Redwood’s hydrometallurgical process achieves a remarkable 95% lithium recovery rate from scrap batteries. The recovered materials are subsequently purified for use in cathode active materials, effectively reducing environmental impact and bolstering domestic supply chains in the US.

We’re building America’s battery supply chain:

✅ First commercial-scale nickel "mine" and only lithium supply to come online in the US in decades.

✅ @Stanford shows we cut CO2 by 40% compared to other recyclers and, at a 15-20 GWh processing scale already!

✅ Environmental…

— Redwood Materials (@RedwoodMat) April 18, 2024

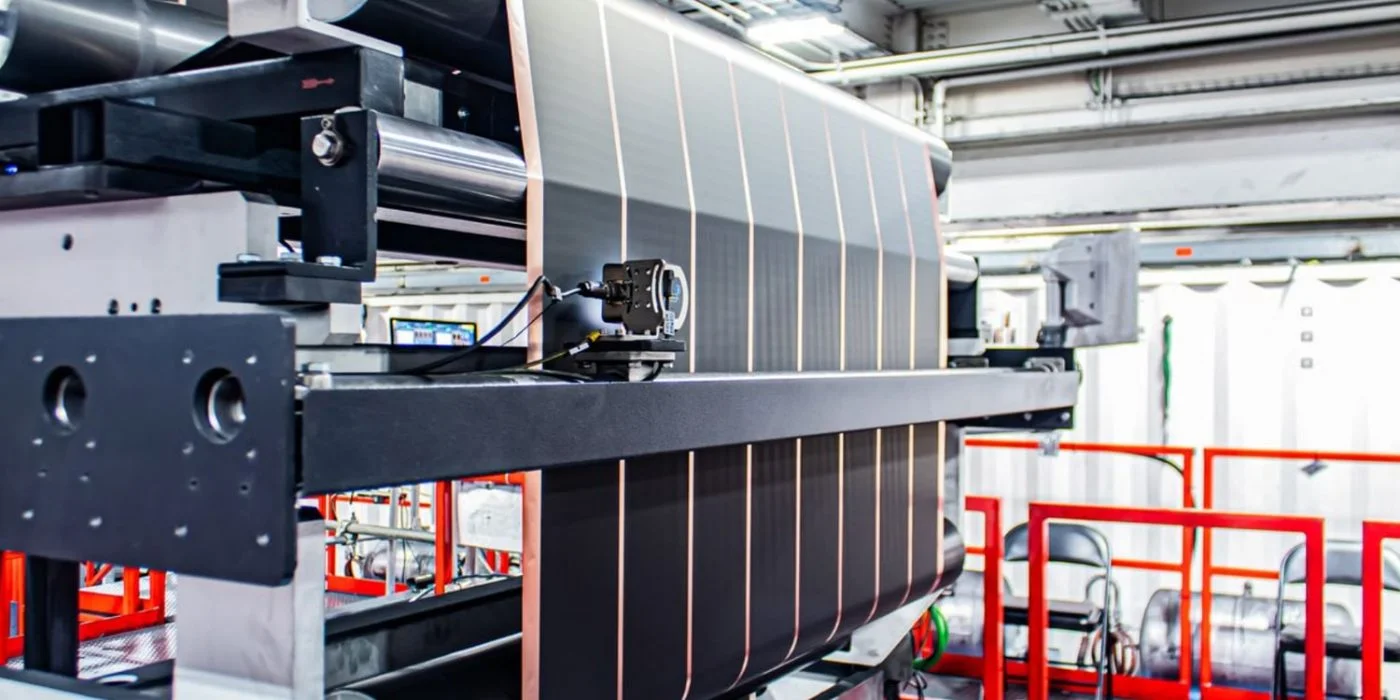

On the other hand, Redwood’s innovative reductive calciner processes various battery feedstocks, including live battery cells, consumer electronics, and electric vehicle modules. The facility is capable of processing more than 40,000 metric tons (approximately 15-20 GWh) of materials annually.

In a statement on its official website, Redwood revealed that it engaged a multidisciplinary team from Stanford University to quantify the environmental footprint of its flowsheet. The study compared Redwood’s lithium-ion battery recycling processes to other recycling technologies, yielding noteworthy findings.

The analysis highlighted a substantial reduction in the environmental impact associated with extraction and transport, a significant concern with conventional mining. Redwood’s closed-loop system was found to reduce this impact to less than 5%, compared to over 30% in conventional mining cycles, showcasing the efficiency of its circular supply chain.

Furthermore, Redwood’s processes were lauded for their energy and resource efficiency. “Compared to traditional methods of processing mined ore into battery-grade materials, our approach is significantly more sustainable. We use 80% less energy, generate 70% less CO2 emissions, and require 80% less water, setting new standards in resource efficiency,” the company stated.