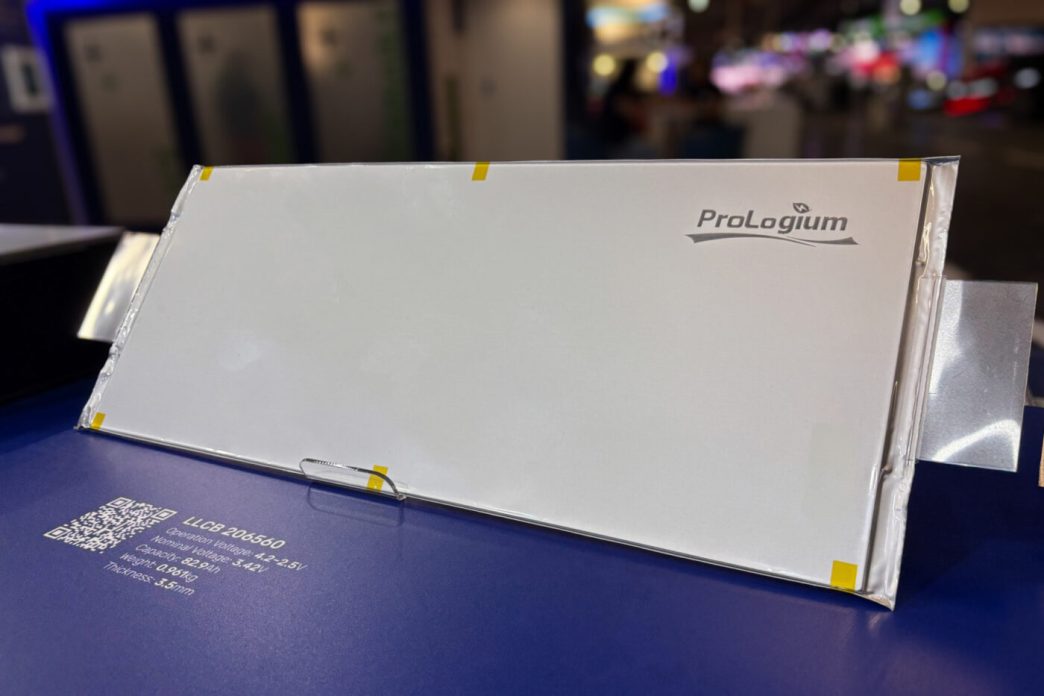

At the Paris Motor Show, Taiwanese company ProLogium showcased its latest innovation: a pure silicon composite anode designed to significantly enhance the performance of electric vehicle (EV) batteries. This development is part of a collaborative effort with a partner from Germany and falls within ProLogium’s specialization in solid-state batteries featuring ceramic electrolytes, referred to as lithium-ceramic batteries (LCB).

ProLogium claims that its new silicon anode technology has achieved an impressive volumetric energy density of 749 Wh/l and a gravimetric energy density of 321 Wh/kg, with expectations to reach 823 Wh/l and 355 Wh/kg later this year. Importantly, these figures represent the system level rather than the individual cell level. To validate its claims, ProLogium engaged TÜV Rheinland to test the new batteries. According to TÜV Rheinland, the battery can charge from 5% to 60% in just five minutes and reach 80% in 8.5 minutes, marking a significant advancement in reducing charging times and improving vehicle range.

Despite these promising specifications, ProLogium has not disclosed specific details regarding the construction of its silicon composite anode. Typically, while silicon anodes can enhance energy density and fast-charging capabilities, they face challenges due to significant expansion and contraction during use, which can lead to shorter battery life. Most commercial EVs currently utilize anodes with lower silicon content, primarily relying on graphite as the active material. ProLogium has yet to clarify how it has addressed the durability concerns associated with its pure silicon anode.

The company emphasizes that the aim of increasing energy density is not solely to achieve longer driving ranges but to create smaller and lighter batteries that maintain similar performance. For instance, an electric vehicle using ProLogium’s battery technology could travel the same distance with a 55 kWh battery as a conventional car with an 83 kWh battery, resulting in a weight reduction of 300 kilograms. This reduction not only lowers energy consumption but also enhances overall range and minimizes the vehicle’s CO2 footprint. Furthermore, ProLogium indicates that the smaller battery design could also lower manufacturing costs, although specifics on cost reductions were not provided. The fast-charging capability of the battery allows for an additional 300 kilometers of range to be added in just five minutes of charging.

While ProLogium has not set a specific launch date for this technology, earlier reports suggested a potential release in 2024. At the Paris Motor Show, the company also demonstrated how its battery packs could be integrated into electric vehicles. This integration has been supported by its partnership with the German FEV Group, established in 2022. ProLogium states that this collaboration represents a shift from merely producing EV components to developing complete battery modules and packs, highlighting its advancements in commercializing its technology.

Thomas Hülshorst, Global Vice President of Electric Powertrain at FEV, commented on the partnership, stating, “Due to the significantly increased energy density of the LLCB cell of 321 Wh/kg, the energy storage system can be designed to be smaller and lighter for a vehicle with a targeted driving range, thus reducing power and space requirements. By combining ProLogium’s visionary technology with FEV’s engineering strengths, we are paving the way for the future of sustainable mobility.”