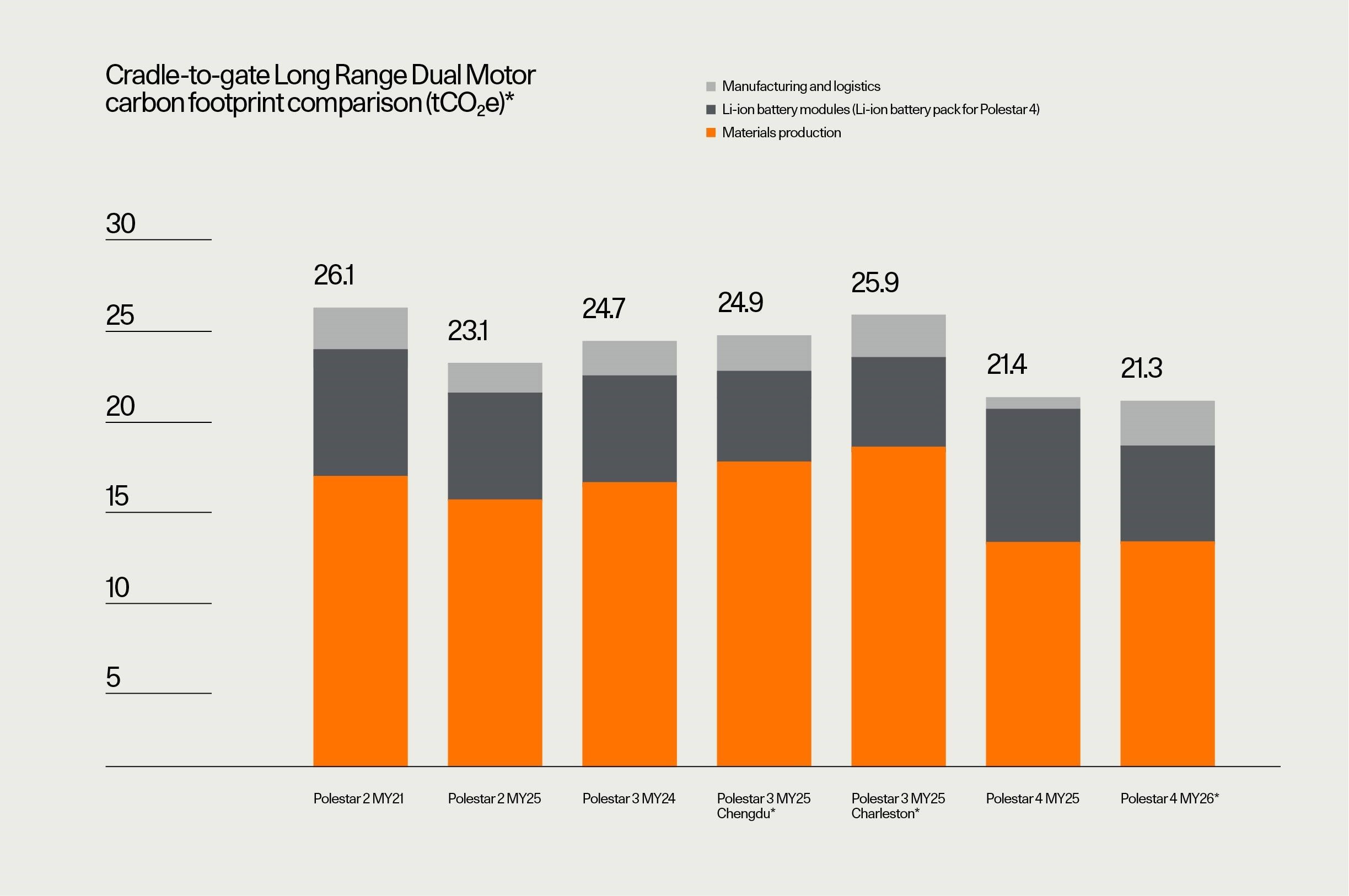

Swedish electric vehicle maker Polestar said it has cut its per-vehicle carbon emissions by nearly 25% since 2020, driven by improvements in materials, battery production, and logistics, according to its fourth Annual Sustainability Report published on Tuesday.

Since it began measuring emissions five years ago, the company said it has achieved a 24.7% reduction in greenhouse gas (GHG) emissions per car sold. Key contributors include a greater use of low-carbon aluminium, renewable electricity across all manufacturing operations, improved battery production processes, and logistics strategies such as incorporating biofuels on select ocean freight routes.

See also: Polestar Cuts Back Retail Network in China as It Shifts Focus to Western Markets

“Polestar has shown that it is possible to decouple growth from climate impact,” CEO Michael Lohscheller said in a statement. “In simple terms, we aim to continue to cut emissions as we accelerate sales. Even though much in the world seems to be going in the wrong direction, we are doubling down on our commitments. When the world zigs, Polestar zags.”

The report also highlighted new developments in the Polestar 0 project — a climate-neutral car initiative launched in 2021 — noting that low-carbon material solutions identified through the project have enabled a potential reduction of 10 tonnes in the cradle-to-gate carbon footprint of the Polestar 2 compared to earlier figures. Steel and aluminium, which make up around 45% of the model’s production emissions, were key focus areas for decarbonisation.

See also: Polestar Q1 Sales Surge 76% as Incentives Bolster Demand Amid Economic Uncertainty

Polestar said the next phase of the Polestar 0 project would involve closer collaboration within the Mission 0 House, a Gothenburg-based research centre combining academic scientists and industry engineers. The facility aims to eliminate GHG emissions in materials and processes, with the potential to commercialise the solutions developed.

The company also reported progress in ethical sourcing and circularity. It has joined the Initiative for Responsible Mining Assurance (IRMA), expanded onsite audits in high-risk sourcing regions, and now tracks materials such as manganese. The Polestar 4 model includes 10% recycled material, reflecting efforts to increase the use of recycled content and boost traceability.