Hyundai Motor Group is trying to overcome the semiconductor chips that have occurred in recent times. One of the ways used to overcome this crisis is to seek the production of homemade Semiconductor Chips.

According to Hyundai, this is important to do to overcome the Semiconductor Chip crisis. Especially considering that many Hyundai car products, especially electric cars, use Semiconductor Chips in the components used.

The move was spearheaded by Hyundai’s auto parts division, Hyundai Mobis.

“This move is part of a strategy to address the risk of shortages in semiconductor supply and strengthen competitiveness in future mobility,” a Hyundai official said in a statement.

The official added that the internal production of Semiconductor Chips will be important for many things in the future.

One of them is for the transition process to electric vehicles which will happen in the near future.

Semiconductor chips have become a key determinant in the competitiveness of future cars as EVs and autonomous vehicles require from 500 to 1,000 semiconductors, three times the amount used by internal combustion cars.

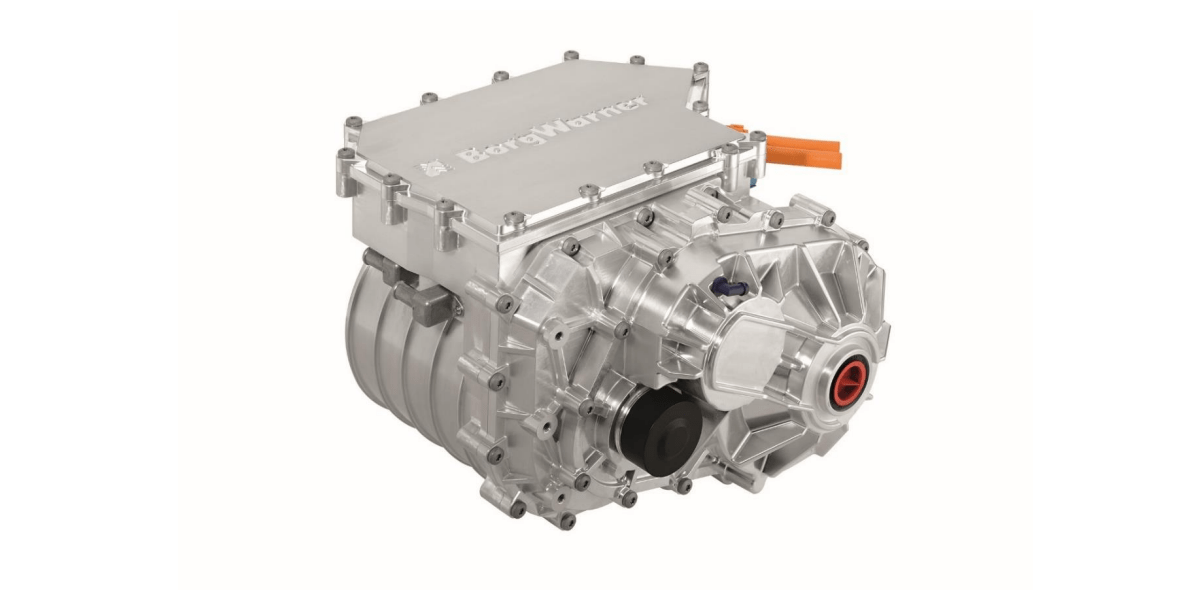

The power semiconductor chip, developed and manufactured by Hyundai Mobis, is one of the key components that can expand the range of EVs.

These high-performance components are becoming an important part of autonomous driving and artificial intelligence (AI).

Around the end of 2020, Hyundai Mobis acquired the semiconductor division of Hyundai Auton, an affiliate of the group. In March last year, the company announced the promotion of semiconductor internalization.

Semiconductor systems must be manufactured in person or shipped via foundry, and Hyundai Mobis will most likely opt for consignment production, as it takes a lot of money and time to build a semiconductor chip factory.