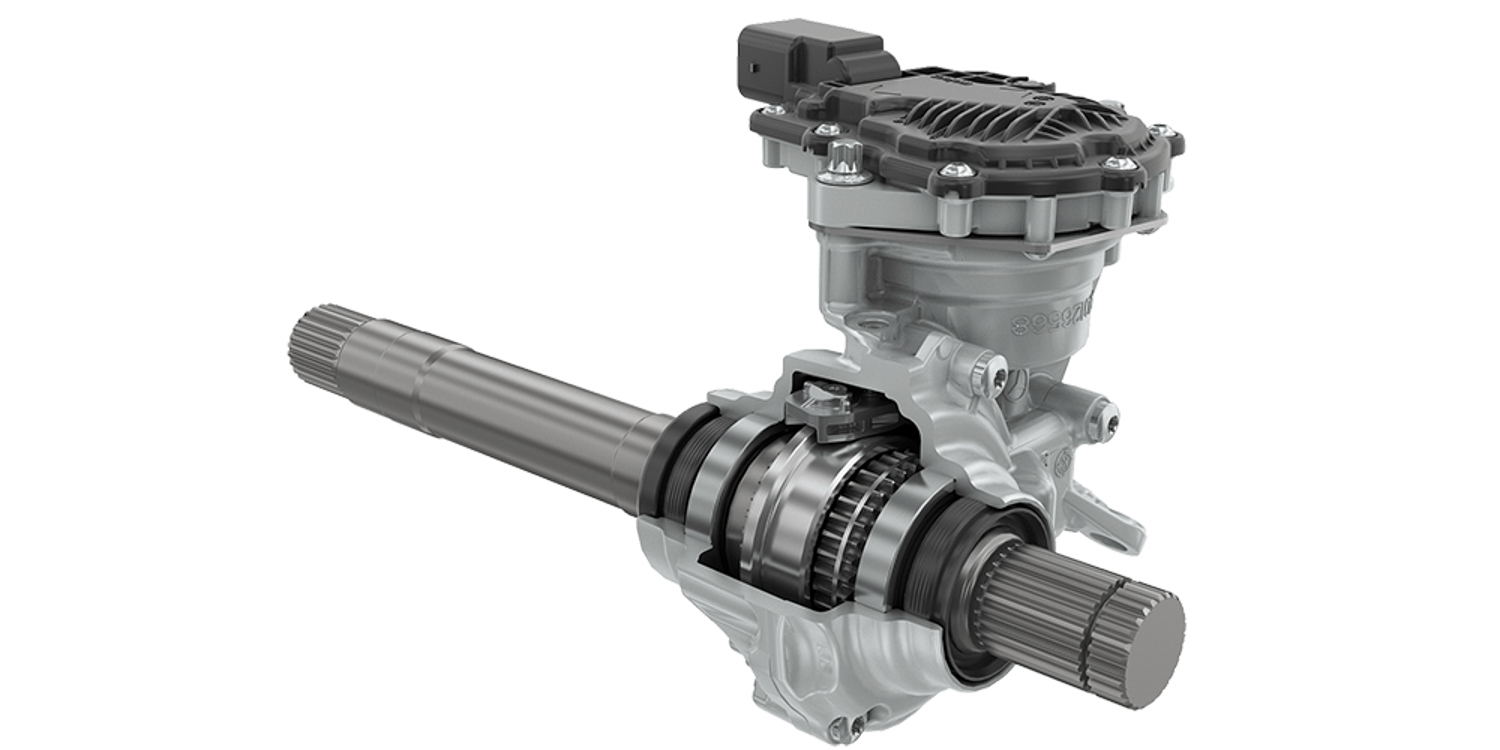

Canadian automotive supplier, Magna, has recently initiated the production of a cutting-edge modular eDecoupling unit designed for battery-electric vehicles (BEVs) from a prominent German premium OEM, which is believed to be Mercedes-Benz. The innovative eDecoupling technology, integrated into BEVs as a complete module, facilitates the disconnection of the electric motor from the drive shaft when propulsion is not required. This energy-saving mechanism reduces consumption and enhances overall efficiency, contributing to an impressive increase in electric range of up to nine per cent.

While Magna has refrained from explicitly disclosing the name of the customer, customary practice for most suppliers, the concept suggests potential applications within the VW Group for the PPE platform used by Audi and Porsche, or Mercedes-Benz. Specifically, the eDecoupling unit is particularly useful in permanently excited synchronous motors (PSM), where the rotating magnetic field generated by the permanent magnets in the rotor induces voltage in the magnetic coils of the stator, allowing energy recovery during deceleration through recuperation. However, this recuperation effect may not be desirable in all-wheel drive electric vehicles with a second electric motor on the front axle, as the front PSM could potentially work against the rear drive unit.

Porsche’s Taycan, for instance, employs a “zero torque control” mechanism for the front PSM, neutralizing its recuperation effect. Other manufacturers like Hyundai implement a mechanical clutch on the front PSM in their E-GMP models. On the other hand, vehicle configurations with different motor concepts, such as asynchronous machines or separately excited synchronous machines, do not require an eDecoupling unit since the aforementioned recuperation challenge does not occur.

Given these considerations, BMW is excluded as a potential customer, as the company utilises externally excited synchronous machines for its current generation of drives. Meanwhile, Mercedes-Benz has already begun production of the EQS and EQE with PSM on the front axle, which would make Magna’s eDecoupling unit delivery too late. However, the unit appears to align perfectly with the upcoming MMA platform’s production start-ups in 2024, where rear-wheel drive is standard, but all-wheel drive options with a second front drive unit will be offered.

The Magna eDecoupling unit is currently manufactured at the company’s facility in Lannach, Austria. Notably, the company plans to extend the technology beyond premium vehicles, as the compact design of the unit allows for scalability across electric and hybrid vehicles ranging from the B segment to SUVs and light commercial vehicles. According to Diba Ilunga, President of Magna Powertrain, the innovative eDecoupling unit complements OEMs’ in-house manufacturing strategies for electric drive systems, providing added package space and weight optimization.