Japan, a former leader in electric vehicle technology, now trails behind China, which has taken the lead in the global EV market. In an effort to understand the advancements driving this shift, Japan’s Central Economic and Trade Bureau recently held a seminar to examine the technology in popular Chinese EVs, focusing on the BYD Atto 3.

Known as the Yuan Plus in China, the Atto 3 impressed Japanese attendees for its affordability and capabilities. In China, this compact electric SUV starts at under $20,000 and offers a 201-horsepower motor paired with a 50-kilowatt-hour battery, providing up to 267 miles (430 km) of range.

For an additional $1,400, customers can upgrade to a 60.5-kWh battery, extending the range to 317 miles (510 km), though European buyers face higher prices due to markups and import tariffs.

The Atto 3 teardown revealed how BYD keeps costs low, achieving savings by producing most of its components in-house and integrating them into a single “E-Axle” system that consolidates multiple elements, including the motor, inverter, AC charger, and battery management system.

This vertical integration, combined with economies of scale, allows BYD to sell a high-performing EV at a competitive price. Kenichi Ito, a seminar organizer, noted that Chinese manufacturers prioritize cost-effective production, though with differing quality standards compared to Japanese automakers.

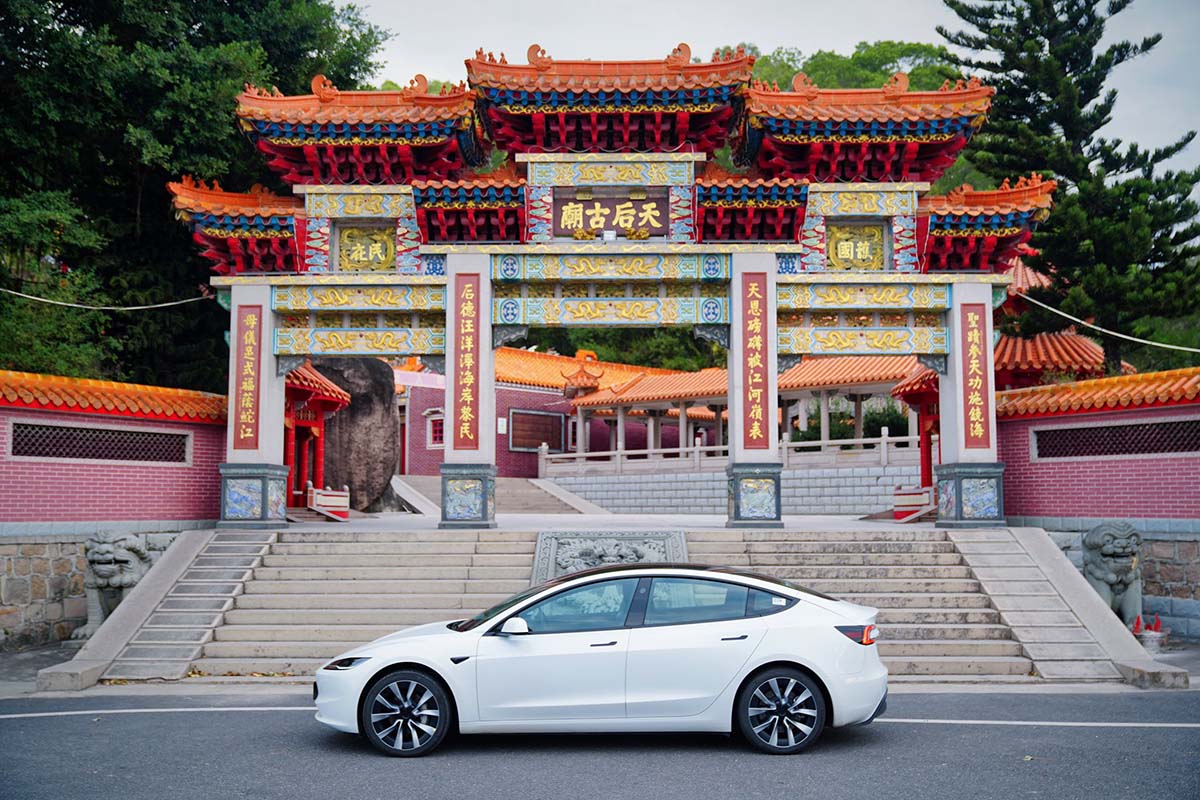

BYD’s success echoes Tesla’s approach, which also emphasizes production efficiency. For example, the Model Y’s frame consists of only two large cast pieces instead of multiple parts, a design that minimizes production complexity and costs.

However, Tesla’s primary focus has shifted toward advancing self-driving technology rather than further streamlining car-building techniques, even as BYD and other Chinese automakers capitalize on cost-effective, high-scale manufacturing to expand their EV market reach.

Source: Nikkei